Novel full-automatic digital controlled lathe

A CNC lathe, fully automatic technology, applied in the field of CNC lathes, can solve problems such as poor work continuity, reduced production efficiency, and low production efficiency, and achieve the effects of improving machining accuracy, improving machining efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

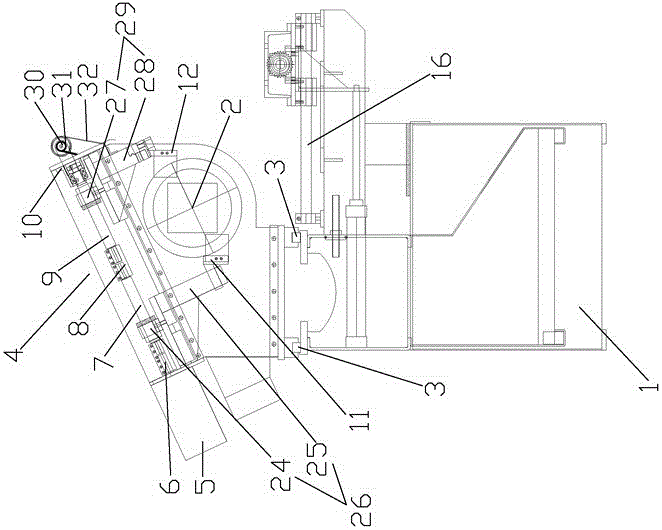

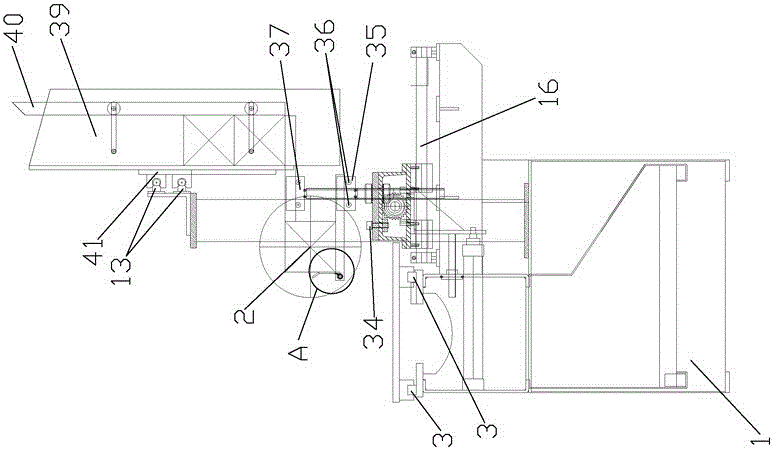

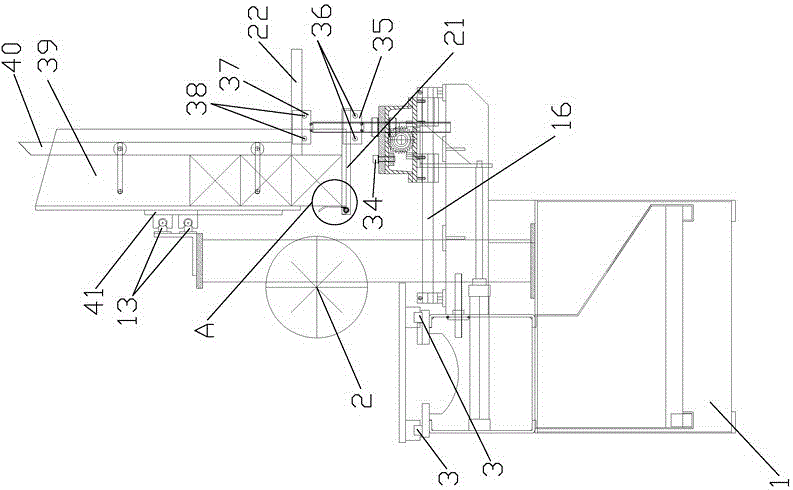

[0044] Below in conjunction with accompanying drawing and implementation the present invention is further described: as Figures 1 to 5 As shown, a new type of full-automatic numerical control lathe includes a frame 1, a main shaft thimble 2, a tool rest 4 slide rail 3 is provided on the frame 1, and it is characterized in that a tool rest 4 is slid on the slide rail 3 of the tool rest 4 , the tool rest 4 is provided with a center frame suitable for workpieces to pass through, the tail end of the tool rest 4 is provided with a servo motor 5, and the servo motor 5 drives one end of the first connecting device 6 through the rotation of the rotating shaft, and the other end of the first connecting device 6 One end is rotatably connected to one end of the reverse screw mandrel 7, the other end of the reverse screw mandrel 7 is rotatably connected to one end of the second connecting device 8, and the other end of the second connecting device 8 is rotatably connected to one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com