Double blade expansion pipe slotting machine

An expansion tube and double-blade technology, which is applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc., can solve the problems of damage and injury, high cost of use and maintenance, low labor efficiency, etc., and achieve safe and convenient use and easy operation. The effect of convenient maintenance and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

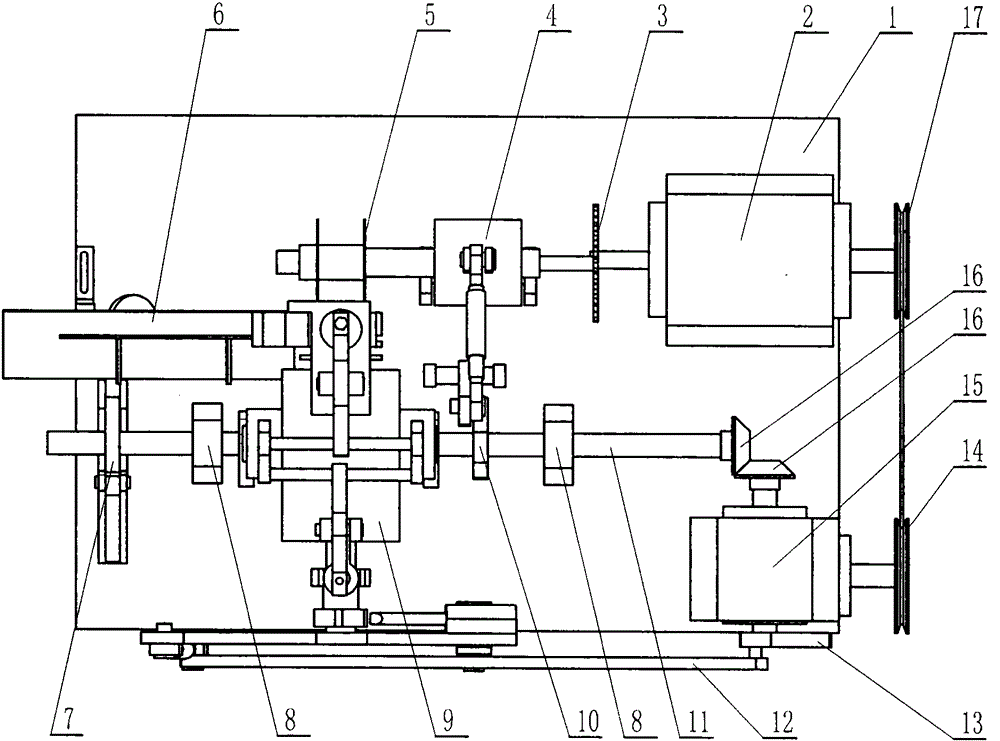

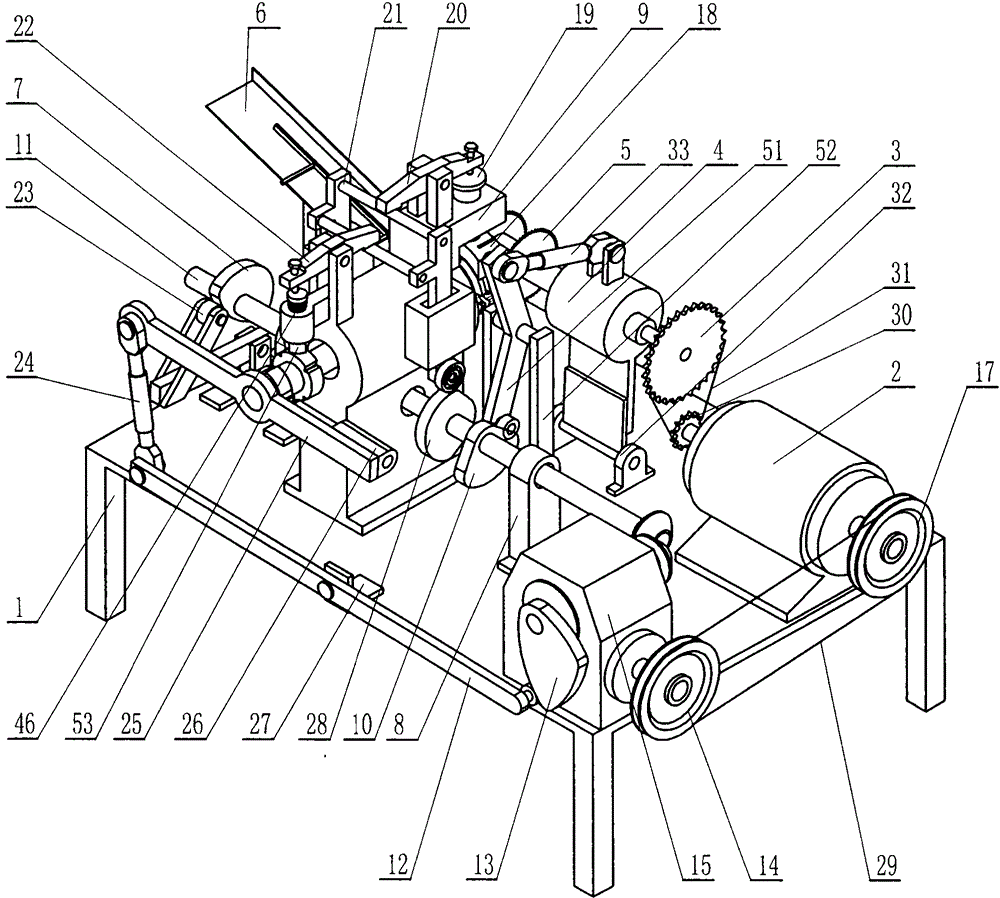

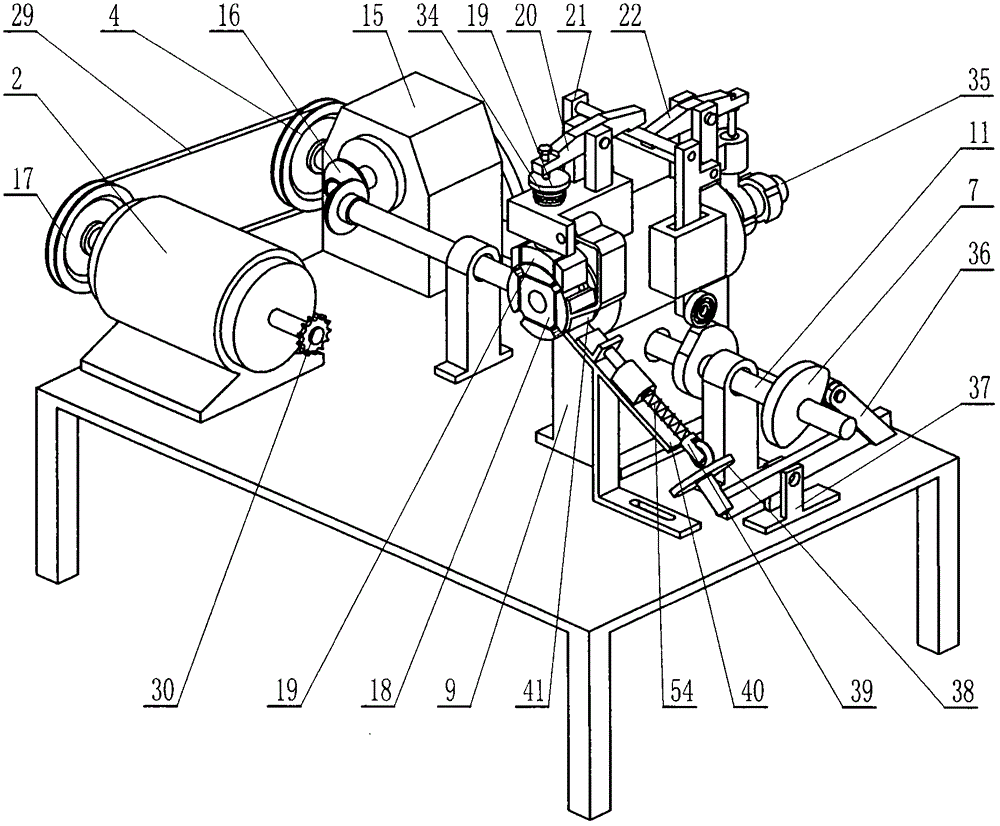

[0032] Specific embodiments of the present invention will be further described below in conjunction with accompanying drawings

[0033]The labels of each component or combination of components in the figure are as follows: 1. Frame; 2. Motor; 3. Sprocket; 4. Double saw blade cutting saw; 5. Saw blade; 6. Feeding slide; 7. Feeding cam; 8 , bearing seat; 9, main base; 10, notch cam; 11, main transmission shaft; 12, long rocker; 13, indexing cam; 14, reducer pulley; 15, reducer; 16, bevel gear; 17 , motor pulley; 18, workpiece fixture; 19, workpiece pressing block; 20, pressing plate; 21, double slider; 22, positioning pressing plate; 23, loading rocker roller; 24, short rocker; 25 , indexing push rod; 26, pawl mechanism; 27, indexing bracket; 28, positioning cam; 29, belt; 30, motor sprocket; 31, chain; 32, cutting machine bracket; 33, cutting push rod; 34 , compression spring; 35, working spindle; 36, loading rocker; 37, loading rocker frame; 38, pushing flat cam; 39, pushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com