A kind of automatic retrieving platform and its transportation method

An automatic retrieving and platform technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of unresolved grasping and playback of specified parts, tedious labor intensity, poor repeatability, etc., and achieve large market development value and can be achieved Enhanced control and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

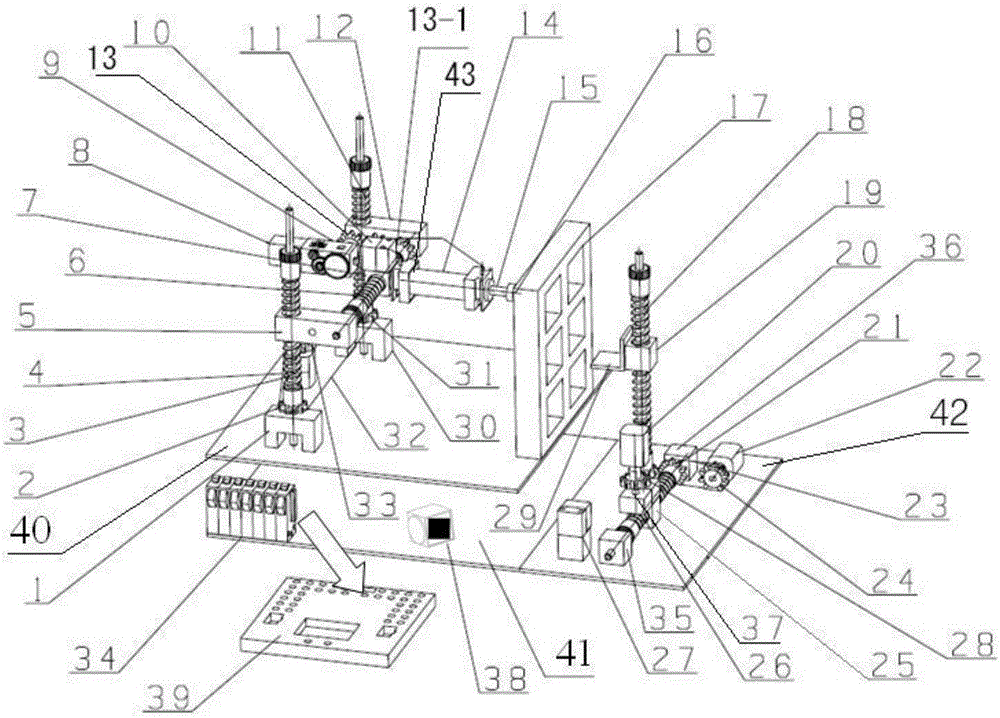

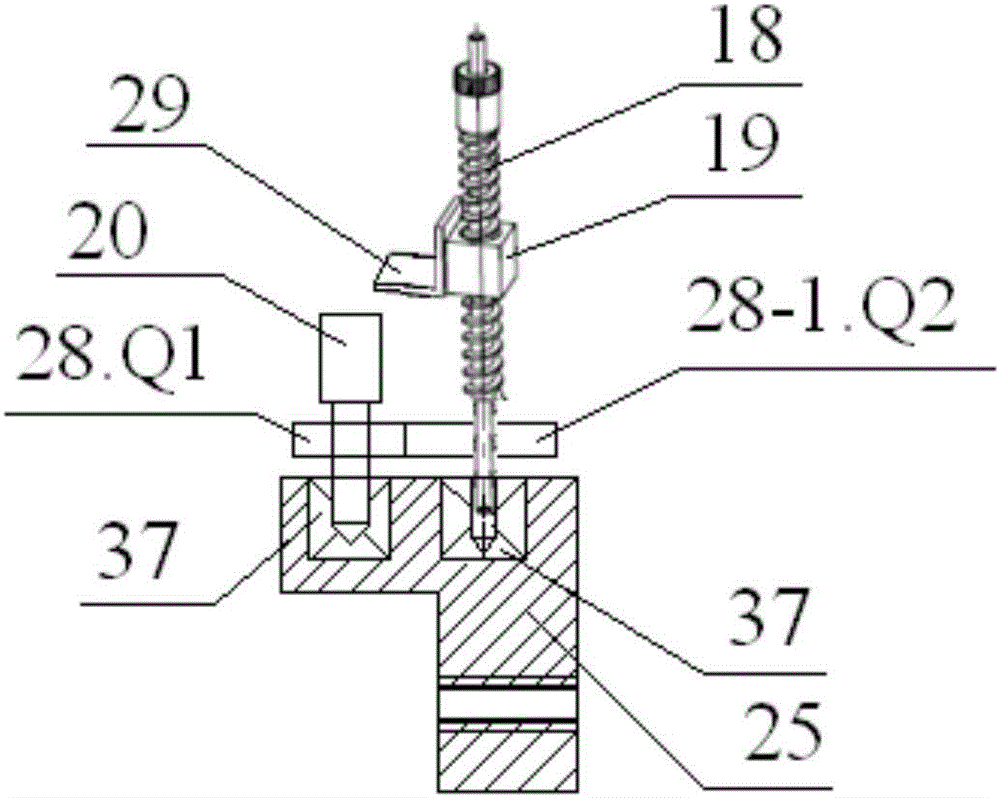

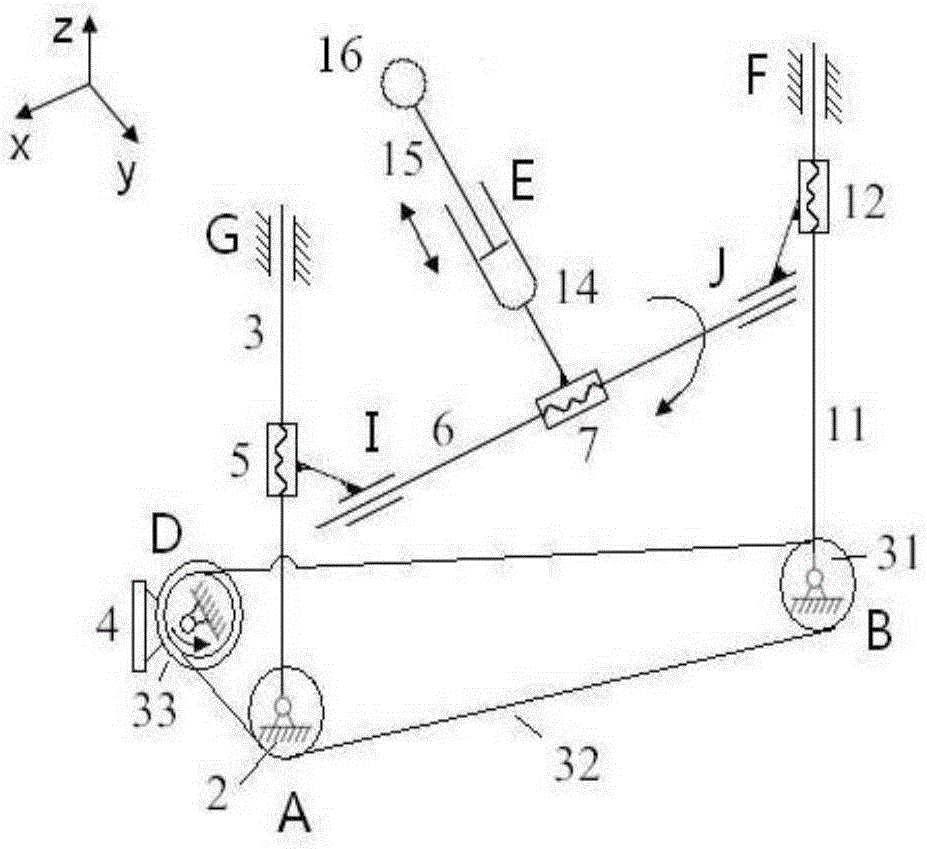

[0036] Such as figure 1 Shown, a kind of automatic retrieving platform comprises upper platform 40, lower platform 41, magnetic force manipulator 43, material cabinet 17, loading moving platform 42, switch 34, controller 39, bar code scanner 27, described upper platform 40 Set directly above the lower platform 41, the lower platform 41 is provided with a switch 34 and an article frame 38; one end of the upper platform 40 is provided with the magnetic manipulator 43, and the other end is provided with the material cabinet 17; The object-carrying platform 42 is connected to the lower platform 41 and is arranged at one end where the material cabinet 17 is located, and the barcode scanner 27 is arranged on the object-carrying platform 42 . The material is packed in the article frame 38, and when picking up the object, it is sucked and placed on the moving platform 42 by pushing the magnetic force manipulator 43, and is transported to the designated position by the moving platform ...

Embodiment 2

[0050] Taking the intelligent warehouse as the realization plan, set the material cabinet 17 to paste red / blue barcodes on the materials at No. 2, white / green barcodes on the materials at No. 4, and white / black barcodes on the materials at No. 6. The color parameters reflected in the color sensor are black, green, blue.

[0051]When picking up the object, press the No. 4 travel switch in the switch 34, the magnetic force manipulator 43 receives the "entry" command, and goes to the No. 4 position of the material cabinet. After the object stage of the platform, the magnetic manipulator resets; at the same time, the object-carrying moving platform transports the No. 4 material to the exit point. When returning the material, place the material (white / green) at the No. 4 position on the barcode scanner 27 at the exit point to wait for scanning, press the electronic switch in the switch 34, and the barcode scanner 27 scans the color barcode at the No. 4 position Identification, whe...

Embodiment 3

[0054] Press the No. 6 travel switch in the switch 34, the magnetic manipulator 43 receives the "entry" command, and moves to the No. 6 matrix grid of the material cabinet 17, and the materials in the No. 6 matrix grid are sucked by the magnetic manipulator 43 and pushed to the load. After moving the platform 42, the magnetic manipulator 43 resets; at the same time, the moving platform 42 carries the material to the exit point. When returning the material, the material (white / black) at the No. 6 position in the moving platform 42 is waiting to be scanned at the exit point, and the electronic switch in the switch is pressed, and the barcode scanner 27 scans and recognizes the color bar code at the No. 6 position. Judging that the color parameter 240≤value≤280, the travel switch No. 6 is triggered, and the magnetic manipulator receives the feedback command of "hand return 6". At this time, the M1 motor 4 and the M2 motor 8 are started, and the magnetic manipulator 43 returns to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com