Air permeable plate and manufacturing method thereof

A manufacturing method and technology of air-permeable panels, applied in chemical instruments and methods, flexible coverings, lamination, etc., can solve the problems of polluting the working environment, shortening the service life, and being unable to use, so as to reduce thermal deformation and reduce heat The effect of accumulation and service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

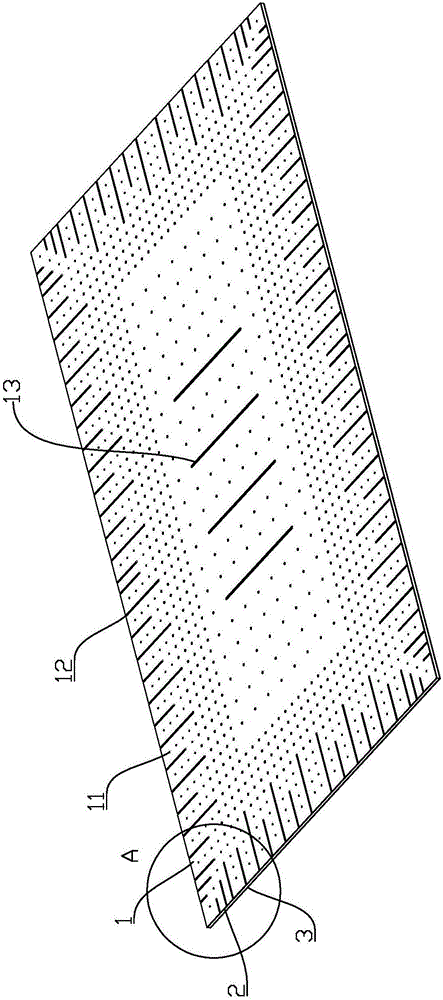

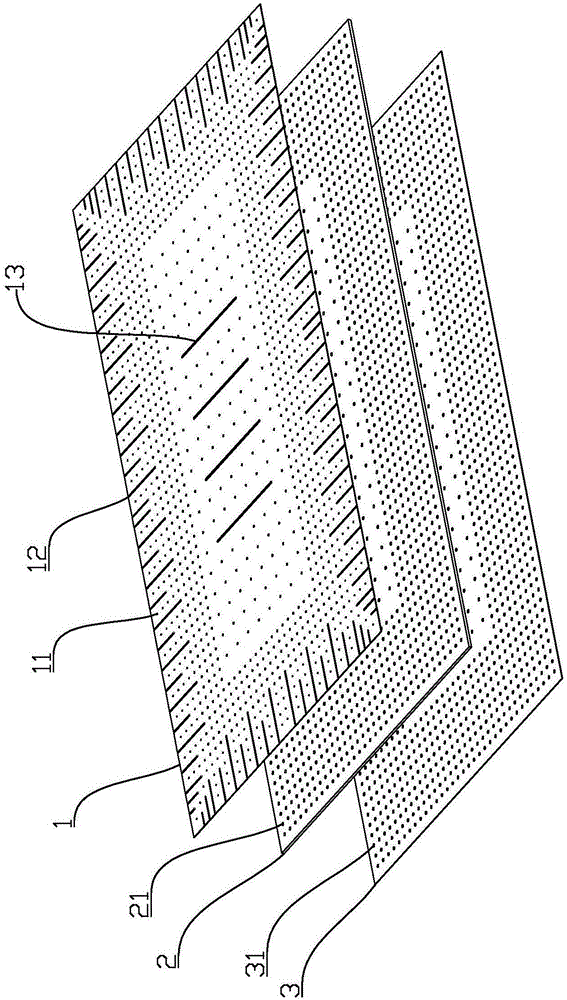

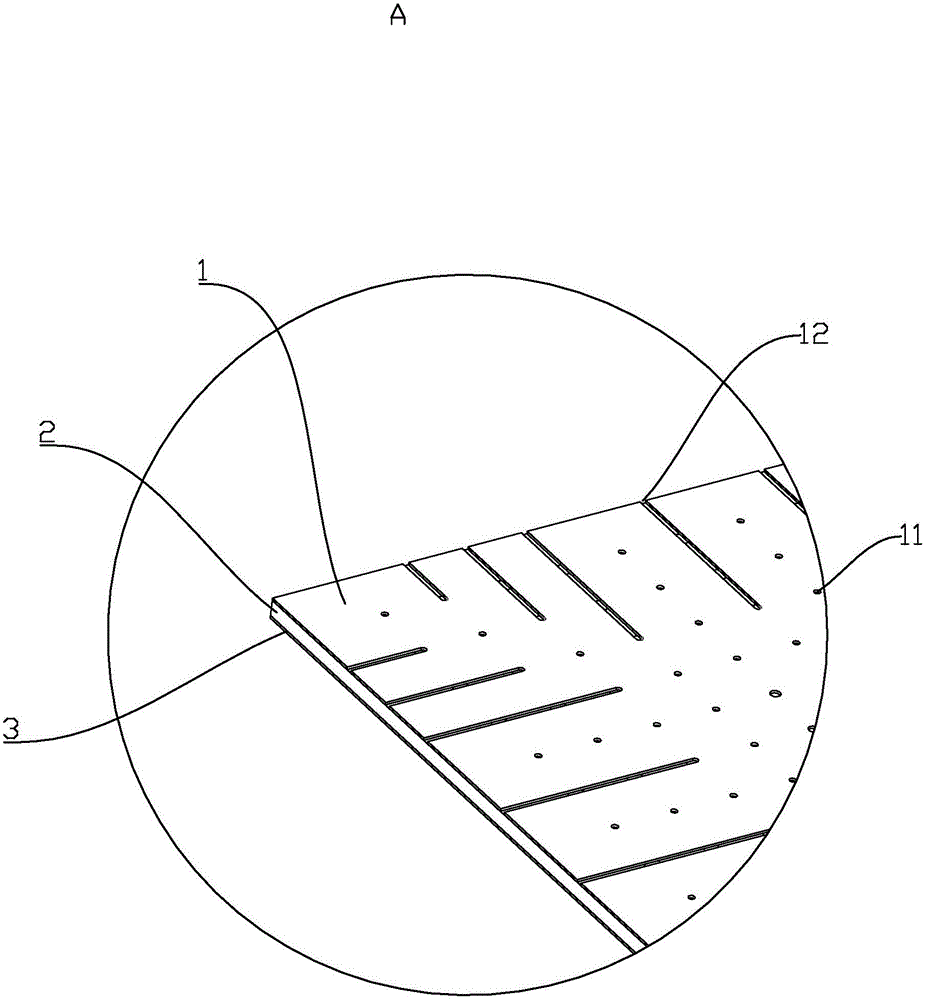

[0023] refer to Figure 1 ~ Figure 3 , the present invention is a kind of air-permeable board, comprises upper board 1, middle board 2 and lower board 3 in layered structure, upper board 1 and lower board 3 are made of wear-resistant materials, middle board 2 adopts high heat dissipation performance and heat resistance Made of deformed material; the upper plate 1 is provided with a number of first air holes 11 and a number of first air grooves 12, the first air grooves 12 are distributed on the periphery of the upper plate 1 and towards the middle of the upper plate 1, and extend out On the upper board 1, the first ventilation groove 12 runs through the upper board 1 in the depth direction; a second ventilation groove 13 is arranged in the middle of the upper board 1, and the second ventilation groove 13 runs through the upper board 1 in the depth direction; on the middle board 2 A second air hole 21 corresponding to the first air hole 11 and the second air groove 13 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com