Exhaust waste heat returning system of lithium methoxide battery series-parallel type hybrid electric vehicle

A technology for hybrid vehicles and exhaust waste heat, which is applied to hybrid vehicles, motor vehicles, power plants, etc., to achieve the effects of saving non-renewable energy and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention, not to limit the present invention.

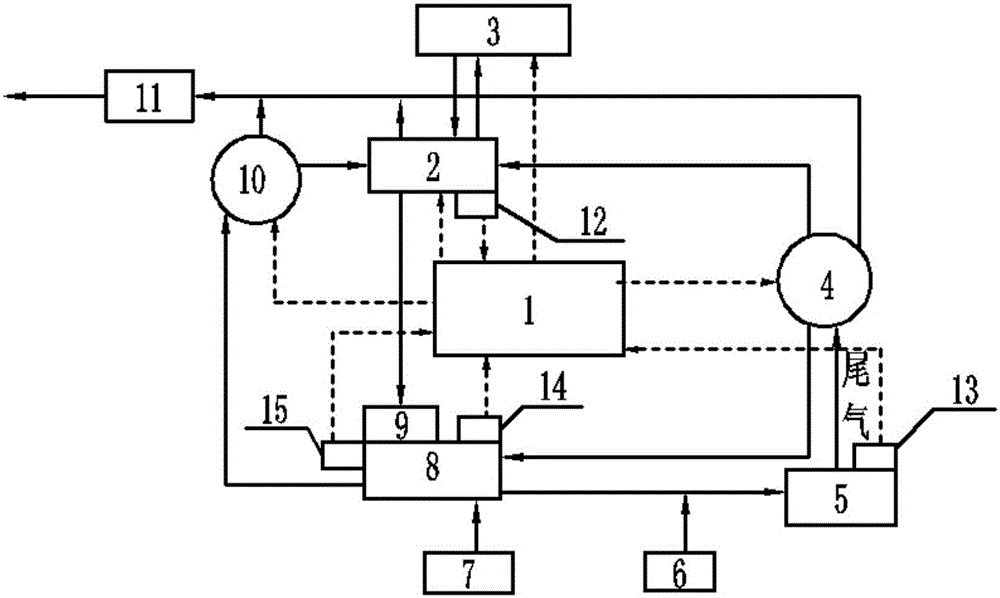

[0015] Such as figure 1 Shown:

[0016] The relatively mature lithium battery 2 power supply device in the electric vehicle market is used to provide power for the small working conditions of the car on the one hand; on the other hand, it provides heat for the methanol gas reforming device, and uses the temperature sensor installed in the gas reforming device 8 to monitor the device. Temperature monitoring, sensors 14, 15 transmit signals to the controller 1, when the temperature in the reformed gas device 8 exceeds the upper-line temperature of the reaction, the controller 1 sends a signal to stop the lithium battery pack 2 from heating the reformed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com