Submachine distributing device of dried noodle packaging machine

A technology of noodle packaging and cloth distributing device, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of high manufacturing cost and high failure rate, and achieve the effect of low manufacturing cost, low work failure rate, simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

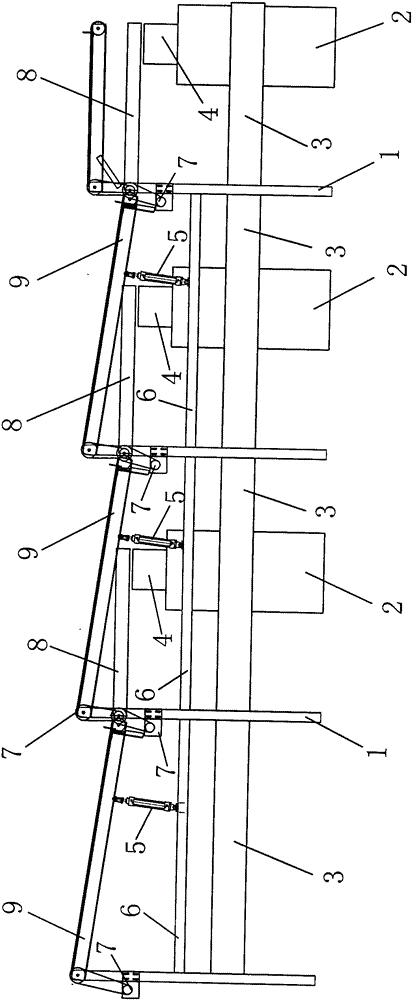

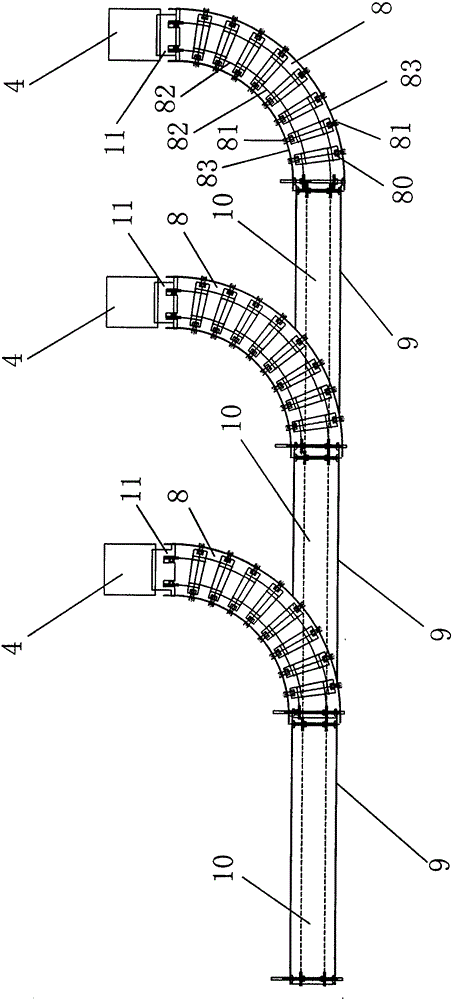

[0009] As shown in the figure, the noodle packaging machine extension distribution device consists of a frame 1, several noodle packaging extensions 2, a noodle slot 3, a cylinder 5, a bracket 6, a motor drive device 7, and several 90-degree arc-shaped guide rails 8 , a plurality of conveyor belt guide rails 9; it is characterized in that, the frame 1 is connected and fixed with a joint groove 3 and a bracket 6, and the upper part of the frame 1 is equipped with a conveyor belt guide rail 9 and a motor drive device 7 matched with it, and the bracket 6 and the conveyor belt guide rail 9 are connected with a cylinder 5; one end of the arc guide rail 8 is also connected to the frame 1, and this end is matched with the motor drive device 7, and the other end of the 90-degree arc guide rail 8 is installed with a slide Panel 11, sliding panel 11 is connected with the face loading port 4 of vermicelli packaging extension 2; Conveyor belt guide rail 9 is provided with transmission belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com