An organic compound fertilizer suitable for sticky soil

A compound fertilizer and cohesive soil technology, applied in the direction of organic fertilizer, organic fertilizer preparation, fertilizer mixture, etc., can solve the problems of increasing plant planting costs, affecting nutrient absorption, poor respiration, etc., to achieve full absorption, improve Absorption effect, effect of improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

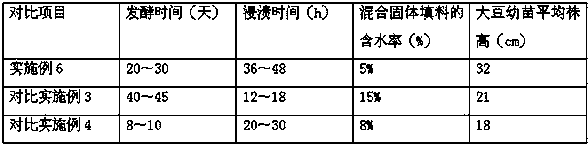

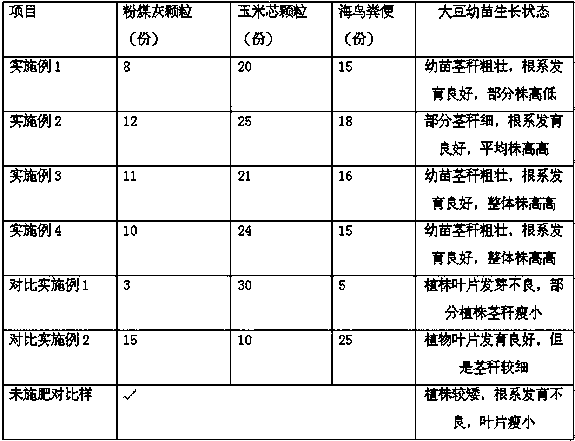

Examples

Embodiment 1

[0025] Embodiment 1: a kind of organic compound fertilizer that is applicable to cohesive soil, the parts by weight of each component in the described organic compound fertilizer are as follows: 8 parts of fly ash particles, 20 parts of soybean cake fertilizers, 15 parts of seabird droppings, corn 20 parts of core particles, 3 parts of potassium sulfate, 2 parts of ammonium phosphate, 5 parts of urea, 0.5 parts of sodium borate, 5 parts of egg shells, and 120 parts of distilled water.

Embodiment 2

[0026] Embodiment 2: a kind of organic compound fertilizer that is applicable to cohesive soil, the parts by weight of each component in the described organic compound fertilizer are as follows: 12 parts of fly ash particles, 30 parts of soybean cake fertilizers, 18 parts of seabird excrement, corn 25 parts of core particles, 4 parts of potassium sulfate, 3 parts of ammonium phosphate, 8 parts of urea, 1 part of sodium borate, 8 parts of egg shells, and 160 parts of distilled water.

Embodiment 3

[0027] Embodiment 3: a kind of organic compound fertilizer that is applicable to cohesive soil, the parts by weight of each component in the described organic compound fertilizer are as follows: 11 parts of fly ash particles, 28 parts of soybean cake fertilizers, 16 parts of seabird droppings, corn 21 parts of core particles, 3.2 parts of potassium sulfate, 2.6 parts of ammonium phosphate, 6 parts of urea, 0.65 parts of sodium borate, 7 parts of egg shells, and 135 parts of distilled water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com