Wafer fixing device for evaporator

A technology of wafer fixation and vapor deposition machine, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc. It can solve the problems of difficult locking, many parts to be cleaned, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

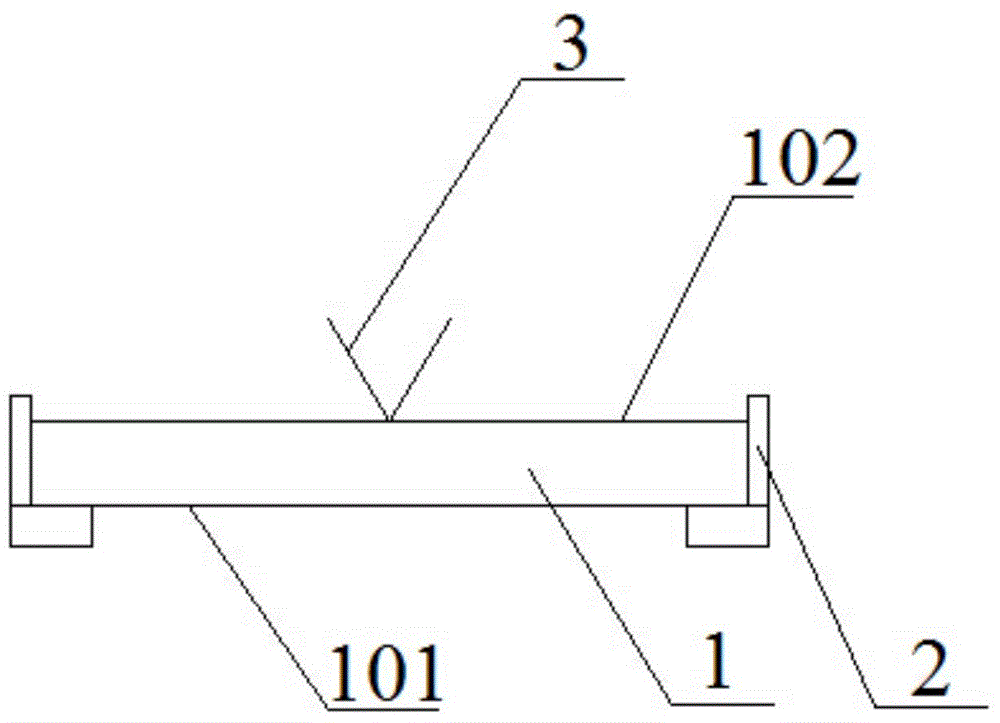

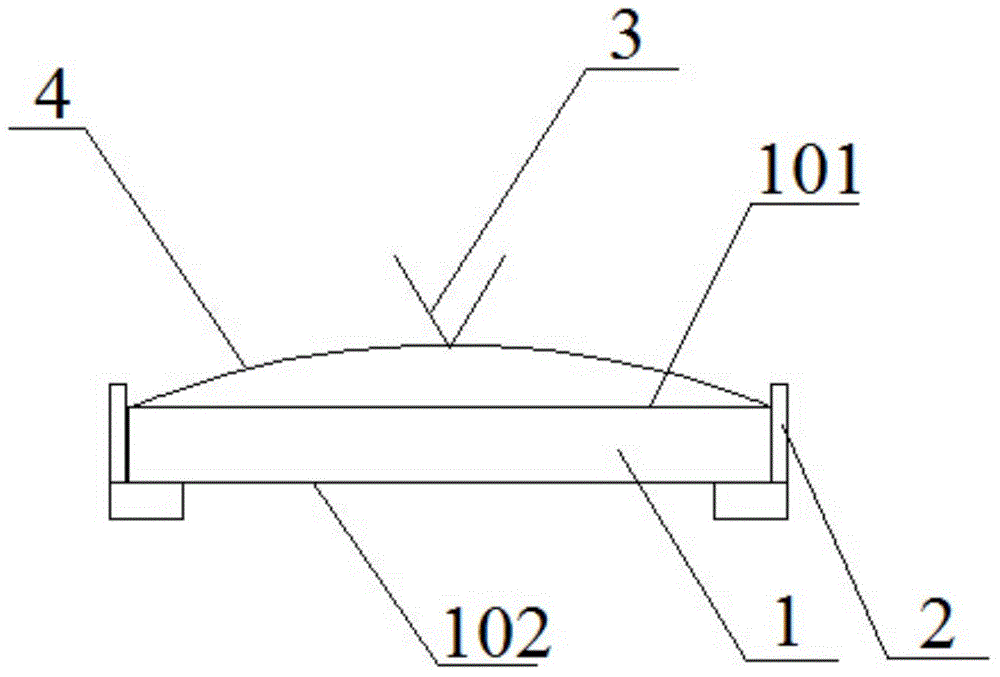

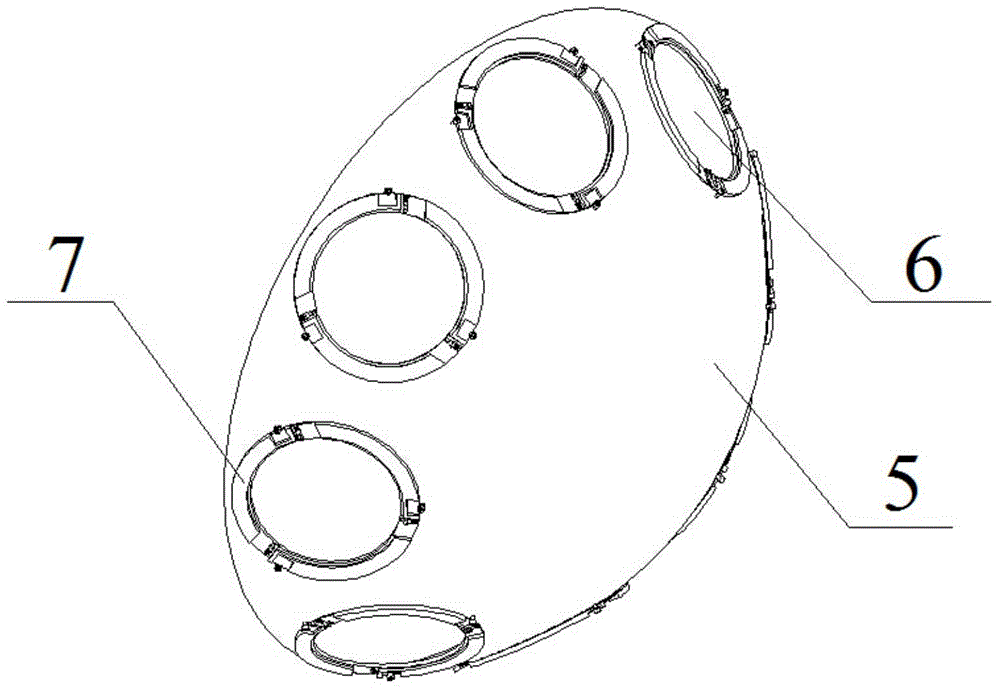

[0032] Attached below image 3 to attach Figure 5 As well as examples, specific embodiments of the present invention are described in further detail. The following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention.

[0033] A wafer fixing device for a vapor deposition machine, comprising a hemispherical support 5, which can also be called a planetary support, and a plurality of through holes 6 are arranged at intervals on the support 5, in order to better implement the present invention In this specific embodiment, the through-holes 6 are evenly spaced along the circumference of the radial section of the bracket 5 and the through-holes 6 are symmetrically arranged in pairs.

[0034] A wafer ring 7 is fixed on each of the above-mentioned through holes 6 , and in this specific embodiment, the wafer ring 7 can be fixed to the through holes 6 through threaded connectors such as screws. The inner ring of the wafer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com