Belt type automatic sisal hemp scutching machine

A hemp machine and sisal technology, applied in mechanical processing, fiber mechanical separation, textiles and papermaking, etc., can solve the problems of unsatisfactory stripping quality, high labor intensity, and finger injury, so as to achieve clean sisal fiber and labor The effect of low strength and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with specific embodiment, further illustrate the present invention.

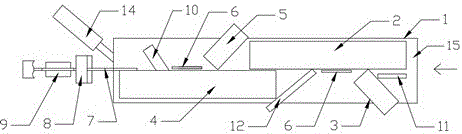

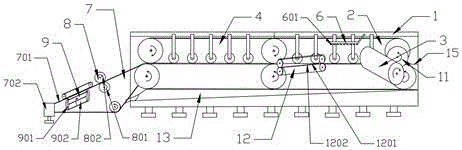

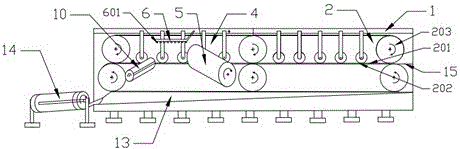

[0023] Such as Figure 1-3 Shown, the belt-type automatic sisal hemp beating machine includes frame 1, feeding hemp platform 15, conveying mechanism, hemp beating mechanism and collection mechanism, and the collection mechanism includes degumming mechanism 6, water pressure mechanism 8, polishing mechanism 9 and Hemp collection mechanism7. There are two groups of the conveying mechanism and the beating mechanism. The first conveying mechanism 2 is provided with the second conveying mechanism 4 at the left rear. The first conveying mechanism 2 and the second conveying mechanism 4 are on the same horizontal plane and are parallel to each other with an interval of 4 cm. , in the conveying direction, the feeding end of the second conveying mechanism 4 is located in front of the discharging end of the first conveying mechanism 2, and the ends of the two conveying mechanisms overlap by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com