Circulation washing system

A technology of circulating washing and circulating pump, applied in the field of washing, can solve the problems of reducing the available space of the washing chamber, the space required for rotation is large, and the spray arm cannot be rotated, so as to achieve a good washing effect, save installation space, and save space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

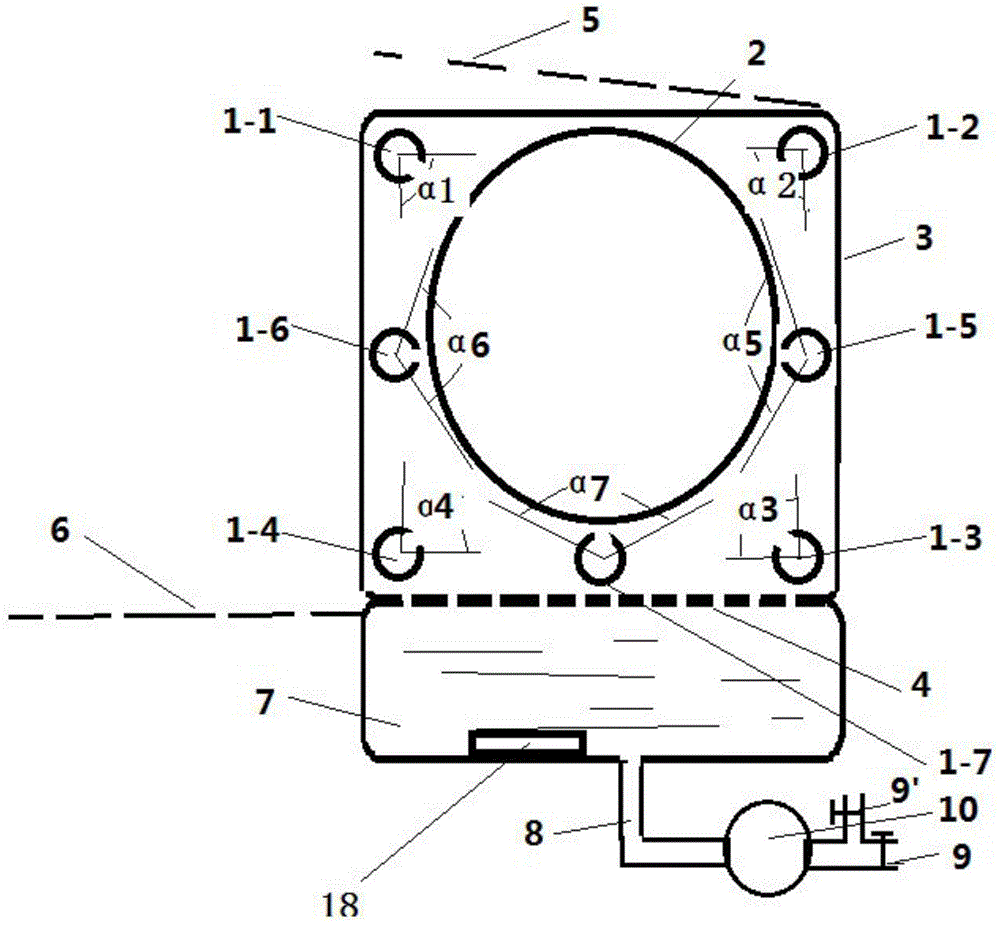

[0055] This example is a dishwasher, intended to illustrate the cycle washing system:

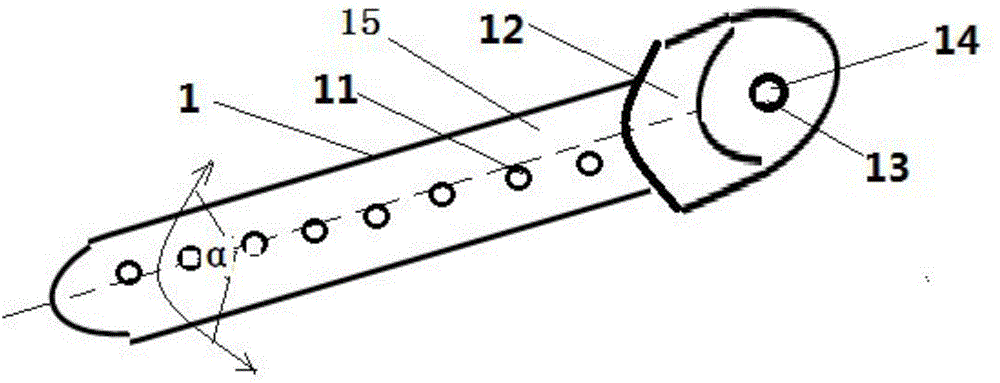

[0056] refer to figure 1 , figure 2 , a dishwasher, comprising: 7 water-driven injection pipes (1-1, 1-2, 1-3, 1-4, 1-5, 1-6, 1-7), the corresponding water-driven injection Spray arm 15 swing angle of pipe (α1, α2, α3, α4, α5, α6, α7), tableware 2, box body 3, water surface 4, upper opening door 5, front opening door 6, water tank 7, connecting pipe 8, solenoid valve (9, 9'), circulation pump 10, heating device 18.

[0057] The box body 3 is relatively closed to prevent water from flowing out or splashing out; the tableware 2 is placed in the middle of the box body 3 . At least one water-driven injection pipe is set around the casing 3, and seven water-driven injection pipes (1-1, 1-2, 1-3, 1-4, 1-5, 1-6, 1-7), the swing angle of the spray arm 15 of each hydraulically driven spray pipe can be set independently, in this embodiment, the corresponding swing angle of the spray arm 15 (α1, ...

Embodiment 2

[0065] Refer to attached Figure 2-4 ,

[0066] This embodiment is a washing machine, and is intended to describe in detail the cycle washing system of the present invention with the washing machine:

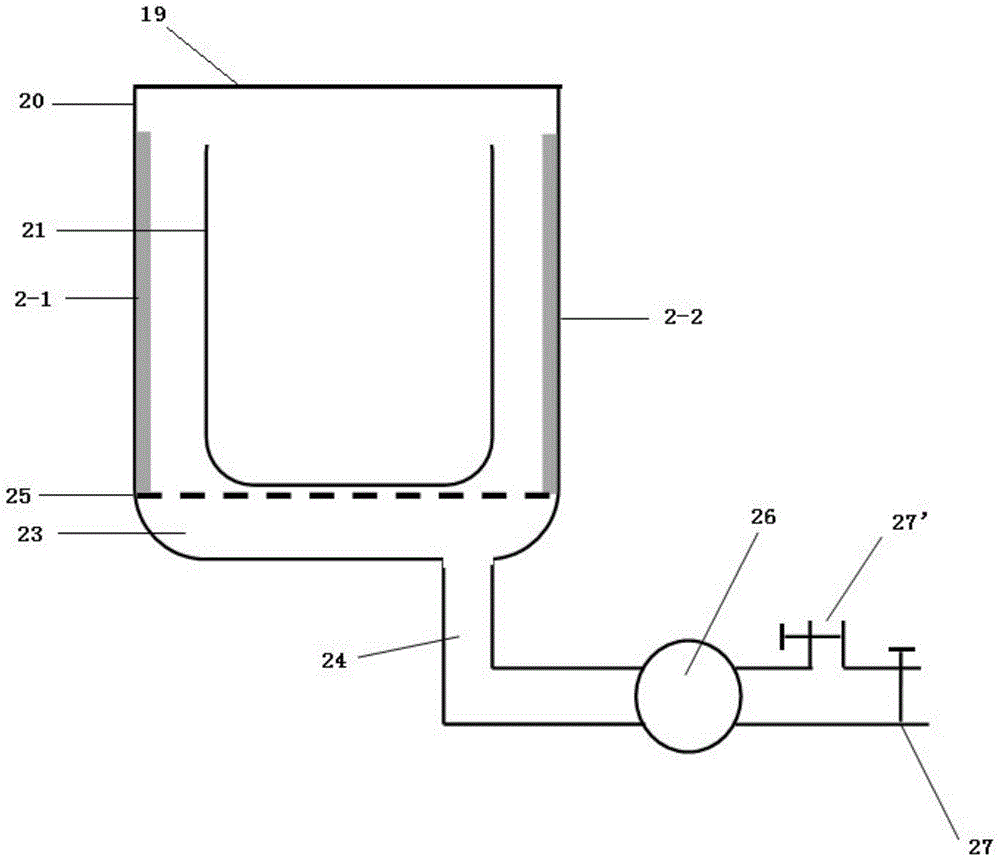

[0067] A washing machine includes an outer tub cover 19, an outer tub 20, an inner cylinder 21, a water tank 23, a connecting pipe 24, a circulation pump 26, a washing machine solenoid valve (27, 27'), and hydraulically driven injection pipes (2-1, 2- 2, 2-3, 2-4).

[0068] The outer barrel cover 19 and the outer barrel 20 are equivalent to the box body, and at least one hydraulic drive injection pipe is arranged around the inner wall of the outer barrel, and the water inlet 13 of the hydraulic drive injection pipe is connected with the drain of the washing machine electromagnetic valve 27'. Ensure that under the hydraulic drive, the spray arm 15 of the hydraulically driven spray pipe 1 can swing around the virtual axis 14 of the hydraulically driven spray pipe, so that the sp...

Embodiment 3

[0076] Refer to attached figure 2 , with Figure 5 , with Image 6

[0077] The present embodiment is a car washing machine, and is intended to describe in detail the cycle washing system of the present invention with the car washing machine:

[0078] The car washing machine comprises a carport 28, a column 29, a water-driven jet pipe (29-1, 29-2), a shed surface 30, a door 31, a drainage pipe 32, a car washing machine tank 33, a car washing machine circulation pump 34, and a car washing machine solenoid valve ( 35,35 '), car washing machine heating device 36, bottom wheel 37.

[0079] The carport 28 includes a column 29 around the column, a retaining surface around the column and a shed surface 30 covered above the column. Carport 28 is relatively closed to prevent water from flowing out or splashing out. There is a door 31 on one side of the carport 28 , and the vehicle can enter into the carport 28 through the door 31 . Around the shed 28, at least one water-driven i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com