A non-destructive assembly and disassembly of double-layer steel casing group structure and construction method of bored pile in deep water area

A technology of bored piles and construction methods, which can be applied to foundation structure engineering, sheet pile walls, buildings, etc., which can solve the problems of increasing project cost, difficulty in ensuring the stability of steel casings, and loss of steel, so as to reduce the difficulty of construction and cost, improve the apparent quality of the pile body, and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. While the invention will be described in conjunction with the preferred embodiments, it will be understood that it is not intended to limit the invention to the described embodiments. On the contrary, the invention is to cover alternatives, modifications and equivalents, which may be included within the scope of the invention as defined by the appended claims.

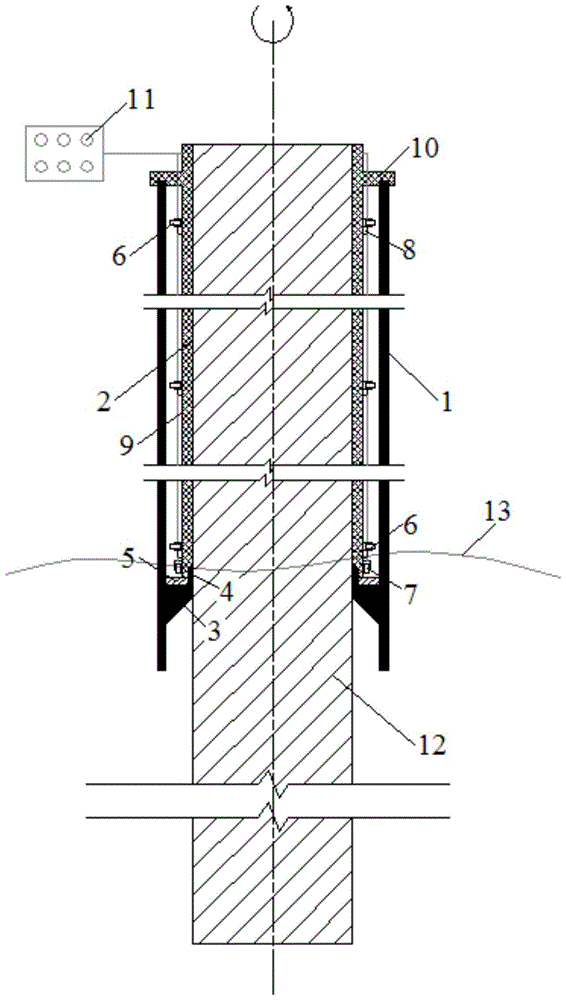

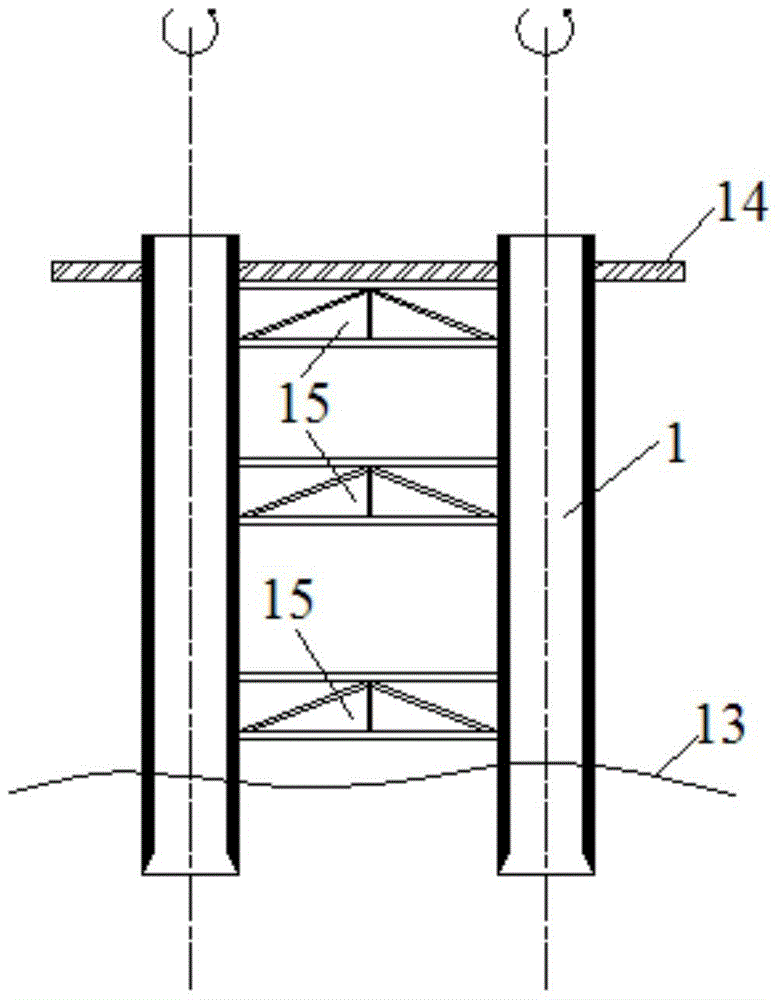

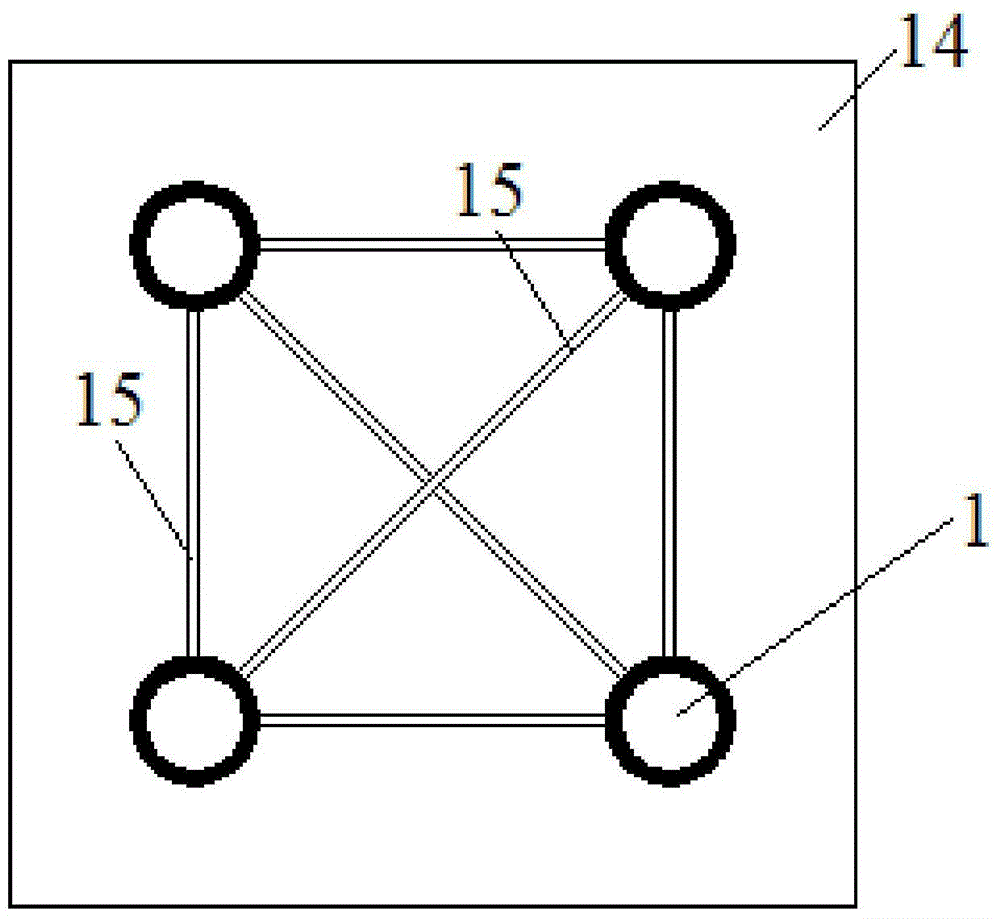

[0030] Such as Figure 1 to Figure 5 As shown, the non-destructive assembly and disassembly of the bored piles in the deep water area is composed of the outer steel casing group and the inner steel casing integrated system. The outer steel casing group is fabricated and lowered as a whole, and the inner steel casing is closed. Hoisting into place, separation, lifting and hoisting out, complete non-destructive assembly and disassembly construction.

[0031] Large-diameter bored cast-in-situ piles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com