Bottom-sealing water-stop structure for deep foundation pit in highly permeable stratum and construction method thereof

A construction method and deep foundation pit technology, which is applied in the direction of infrastructure engineering, excavation, protection devices, etc., can solve the problems of difficult targeted compensation grouting, difficulty in judging leaking parts, high grouting costs, etc., to solve the problem of pit bottom Uplift, ensure water isolation effect, increase earth pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

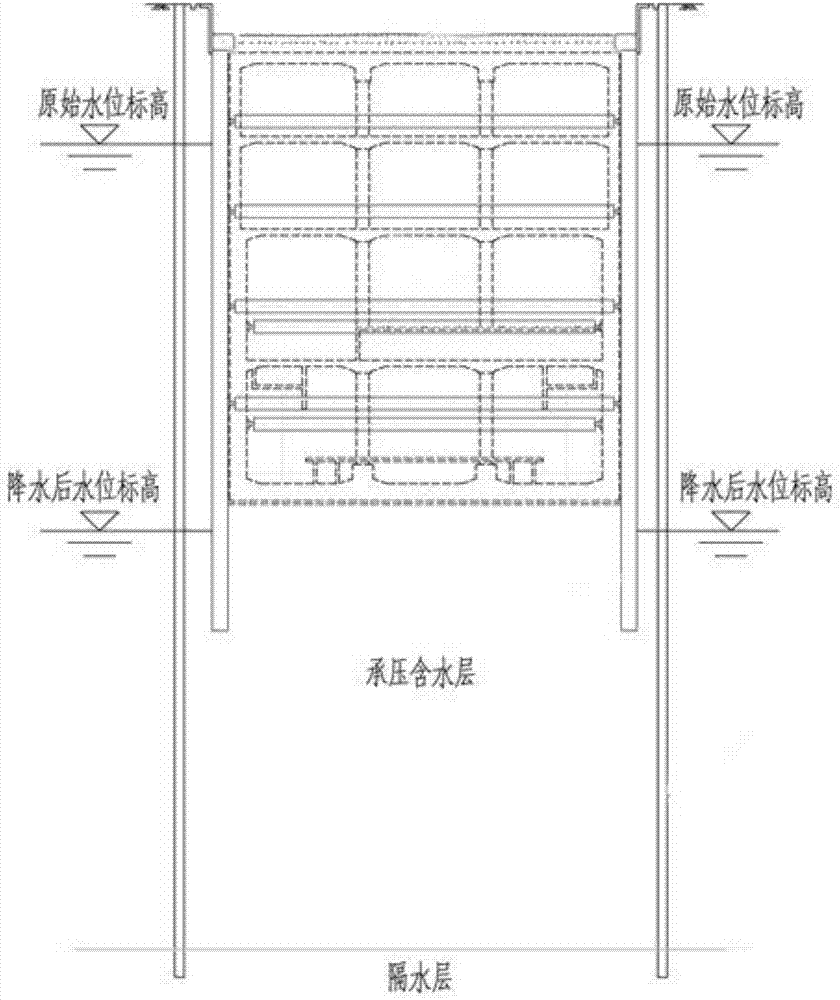

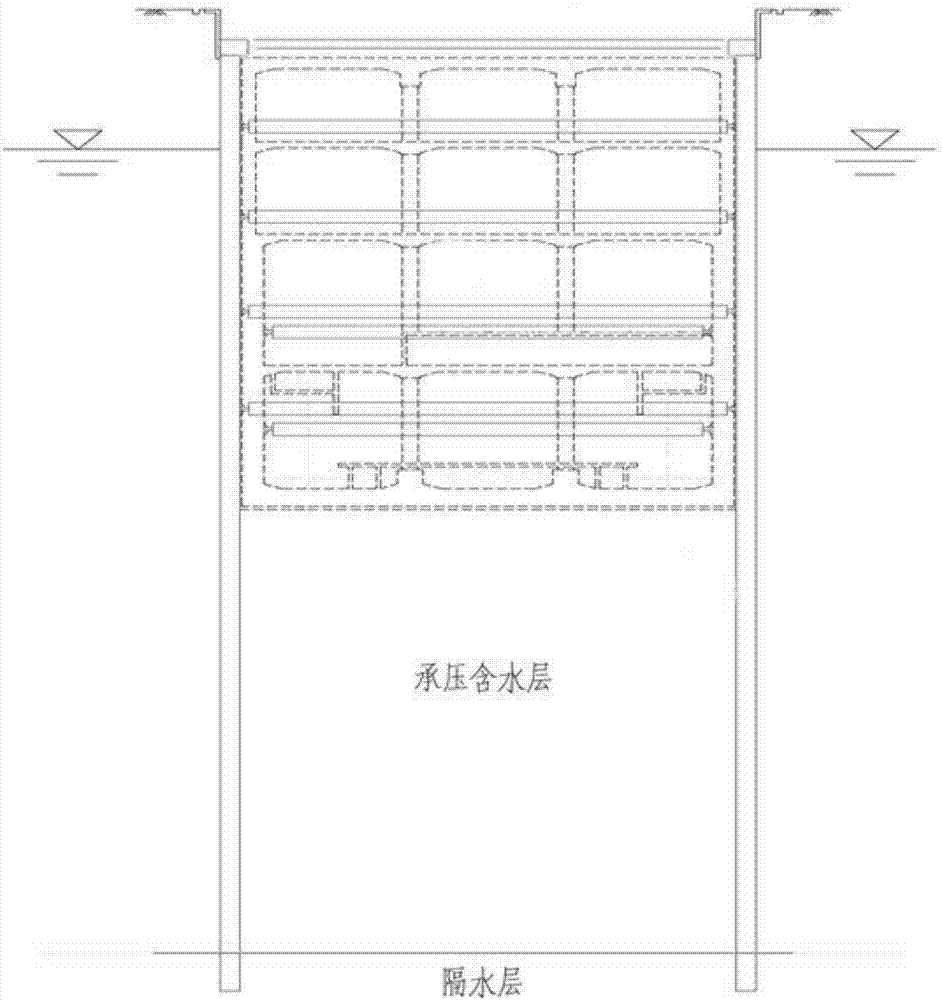

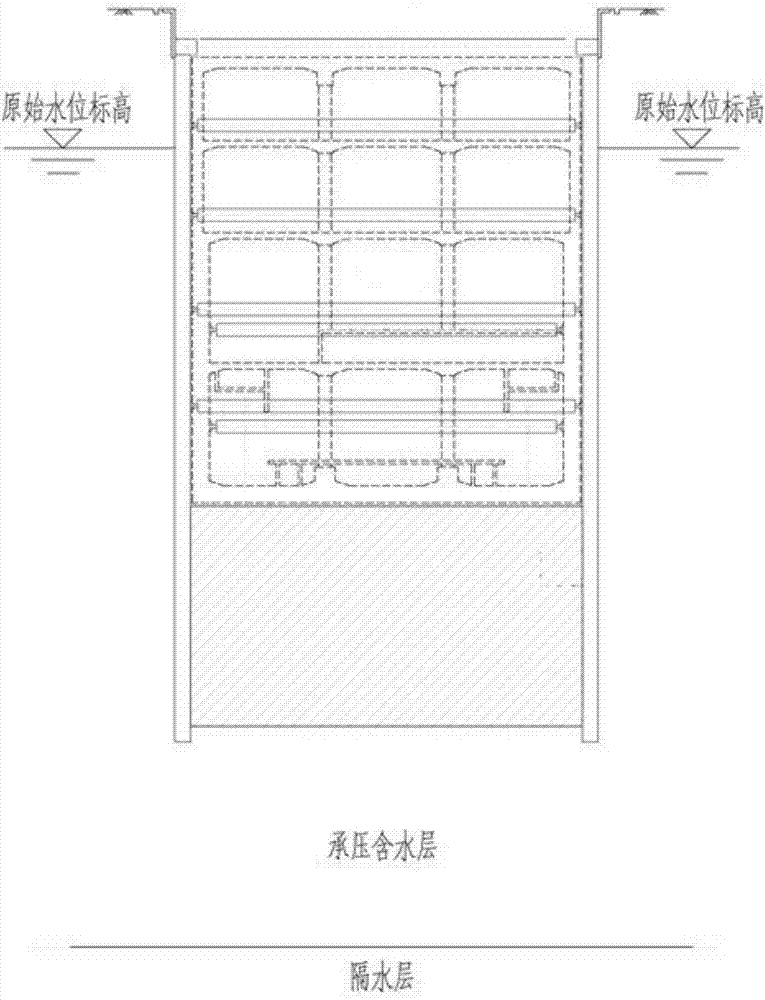

[0046] like Figure 4~5A deep foundation pit bottom seal and water-stop structure in strong permeable stratum is shown, including an underground diaphragm wall 1, an underwater plain concrete board 2, a reinforced concrete partition wall 3, an uplift pile 4 and an inner support 6, and the underground diaphragm wall 1 (equivalent to The water-stop curtain) is placed around the foundation pit by pouring, the inner support 6 is supported on the underground diaphragm wall 1, and the reinforced concrete partition wall 3 is arranged between the underground diaphragm walls 1, and the reinforced concrete partition wall 3 is formed through the underground diaphragm wall Formed by construction, the reinforced concrete partition wall 3 on each two sides and the underground diaphragm wall 1 are enclosed at the base to form a pouring warehouse, and an uplift pile 4 is poured under the base in the warehouse, and the reinforced concrete partition wall 3 and the underground diaphragm wall 1 A...

Embodiment 2

[0048] like Figure 4~5 In the bottom-sealing and water-stopping structure of a deep foundation pit in a strong water-permeable formation, on the basis of Example 1, a 0.5m-thick crushed stone layer 5 is laid on the underwater plain concrete slab 2, and a drainage blind pipe is arranged in the crushed stone layer. Eliminate the seepage water in the warehouse by separate warehouses to ensure the dry operation of the floor construction.

Embodiment 3

[0050] like Figure 4~5 In the bottom-sealing and water-stopping structure of a deep foundation pit in a strong water-permeable stratum, on the basis of Example 1, a groove is provided at the joint between the reinforced concrete partition wall 3 and the underwater plain concrete board 2; A groove is provided at the connection between the pile 4 and the underwater plain concrete board 2; a groove is provided at the connection between the underground diaphragm wall 1 and the underwater plain concrete board 2. In order to increase the shear resistance between the underwater plain concrete slab 2 and other support interfaces and ensure the waterproof effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com