Multi-functional diaphragm vacuum pump

A multi-functional, vacuum pump technology, applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of cumbersome vacuum degree and pumping rate, reduce operating and maintenance costs, small size, stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

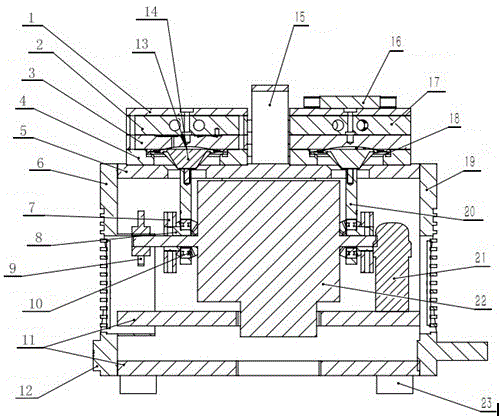

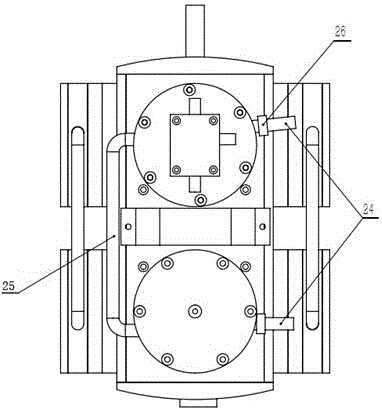

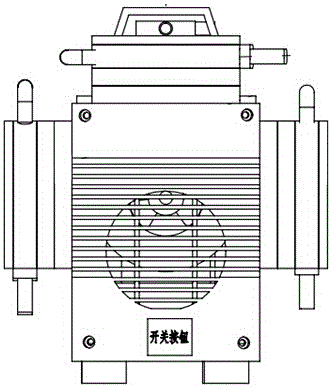

[0014] like figure 1 , 2 As shown in , 3, the multifunctional diaphragm vacuum pump includes a ventilation top plate 1, a ventilation middle plate with inlet and outlet air pipe joints 24 left 2 and a ventilation middle plate right 17, a ventilation bottom plate 3, and an elastic rubber 18 inside. The air exchange seat 4, the upper cover 5, the control switch 12 below and the housing composed of the control switch cover 6, the control wire cover 19, and the middle and lower bottom plates 11 are installed. The pipe connecting pipe 25 is connected, the top of the casing is provided with a handle 15 and the ventilation top plate is provided with a branch controller multi-directional joint 16, the bottom of the casing is provided with a foot pad 23, and the interior of the casing is driven by a motor 22 connected to a capacitor 21 The three-way eccentric wheel 20 drives the rubber diaphragm 14 through the three-way eccentric wheel connecting rod 7. The three-way eccentric wheel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com