Surrounding type continuous drying machine

A dryer and wrap-around technology, which is applied in strip, sheet, wrap-around continuous dryers, drying of granular materials, lumps, and air-drying fields, which can solve the problem that ecological water cannot be recycled and continuous operation cannot be performed. , single use and other problems, to achieve the effect of beautiful appearance, compact structure design and wide use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

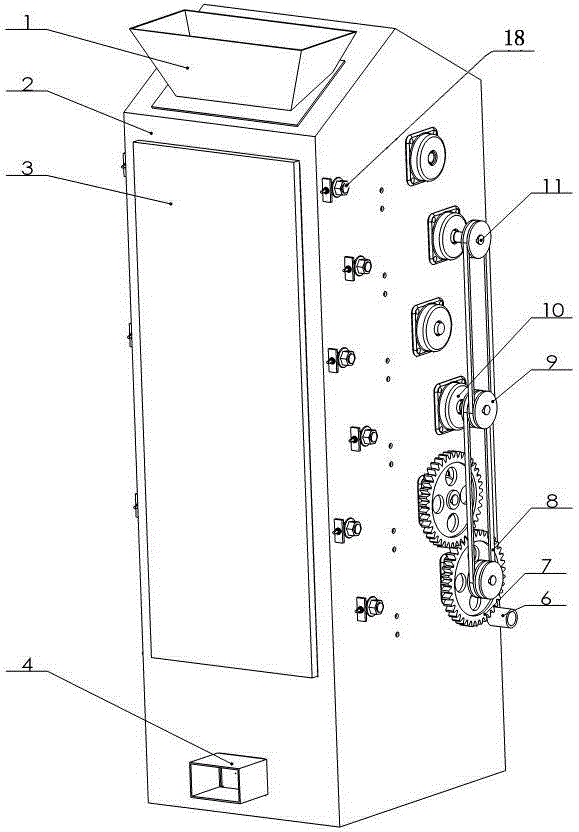

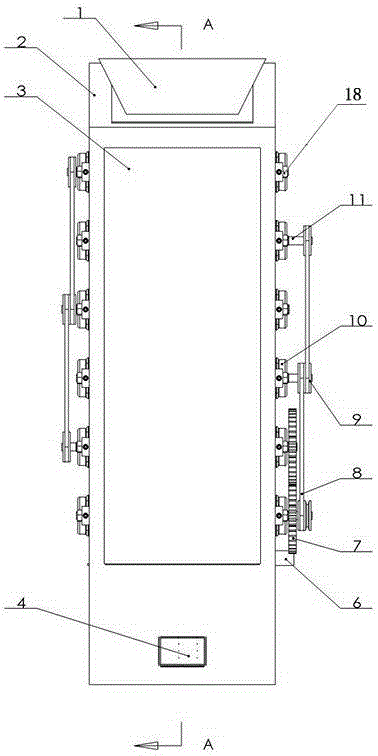

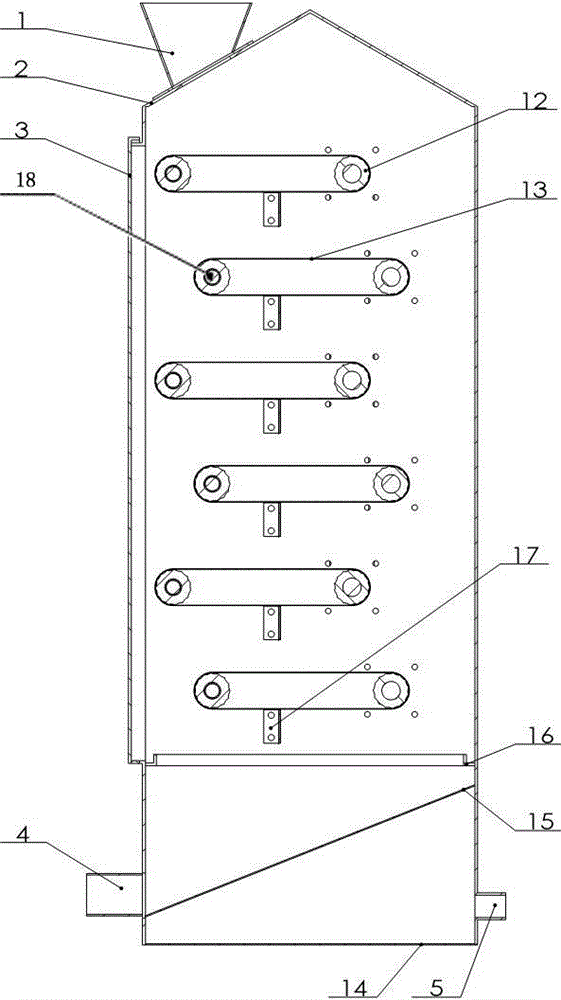

[0018] Example 1: as attached figure 1 , figure 2 , image 3 As shown, the present invention installs the casing 2 on the lower bottom 14; an inclined air guide plate 15 is installed in the lower inner part of the casing 2; A discharge port 4 is installed in parallel on the outer casing 2 on the inclined side; a plurality of groups of parallel transport pulleys 12 are installed in the upper part of the air guide plate 15; the transport pulleys 12 are driven by a transport belt 13; There are multiple sets of bearings 10 and the main transport pulley shaft 11 and the slave transport pulley shaft 18 installed on the left and right sides of the belt; the bearing 10 of the slave transport pulley shaft 18 is installed inside the transport pulley; the main transport pulley shaft 11 and the bearing 12 is used together; it is fixed on the housing 2 from the transport pulley shaft 18; two gears 7 are installed on any two adjacent main transport pulley shafts 11 outside the casing 2, ...

Embodiment 2

[0019] Example 2: as attached image 3 As shown, a cleaning window 3 is installed in front of the casing 2, which can quickly clean the materials inside the machine that stick to the conveyor belt 13 and the inside of the casing 2, and clean the machine.

Embodiment 3

[0020] Example 3: as attached image 3 As shown, a scraper plate 17 is fixedly installed on the lower casing of the conveyor belt 13, which can scrape off the materials adhered to the conveyor belt 13 when the machine is running.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com