Dropping impact test platform

An impact testing and platform technology, applied in impact testing, testing of machine/structural components, measuring devices, etc., can solve the problems of limited application range, difficulty in accurate impact speed, simple structure, etc., to achieve a wide range of applications and ensure accuracy , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

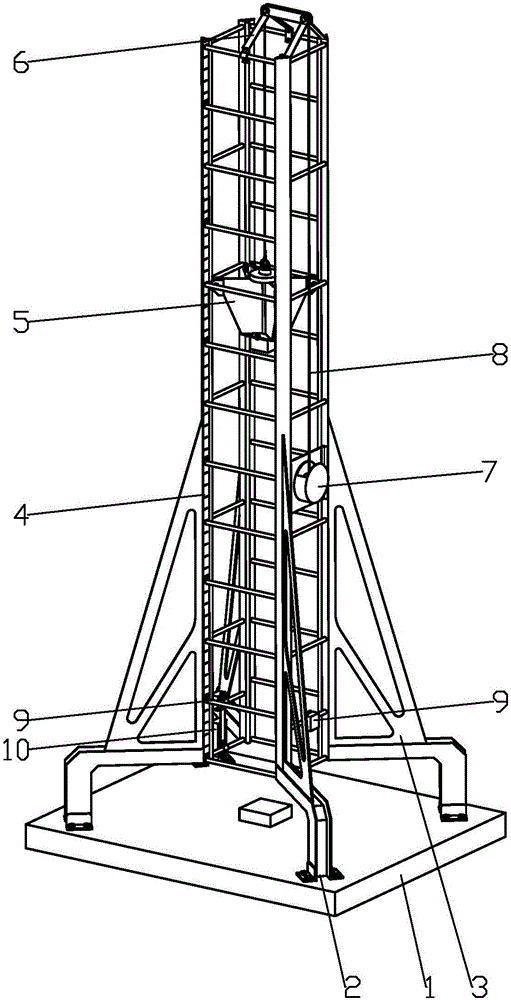

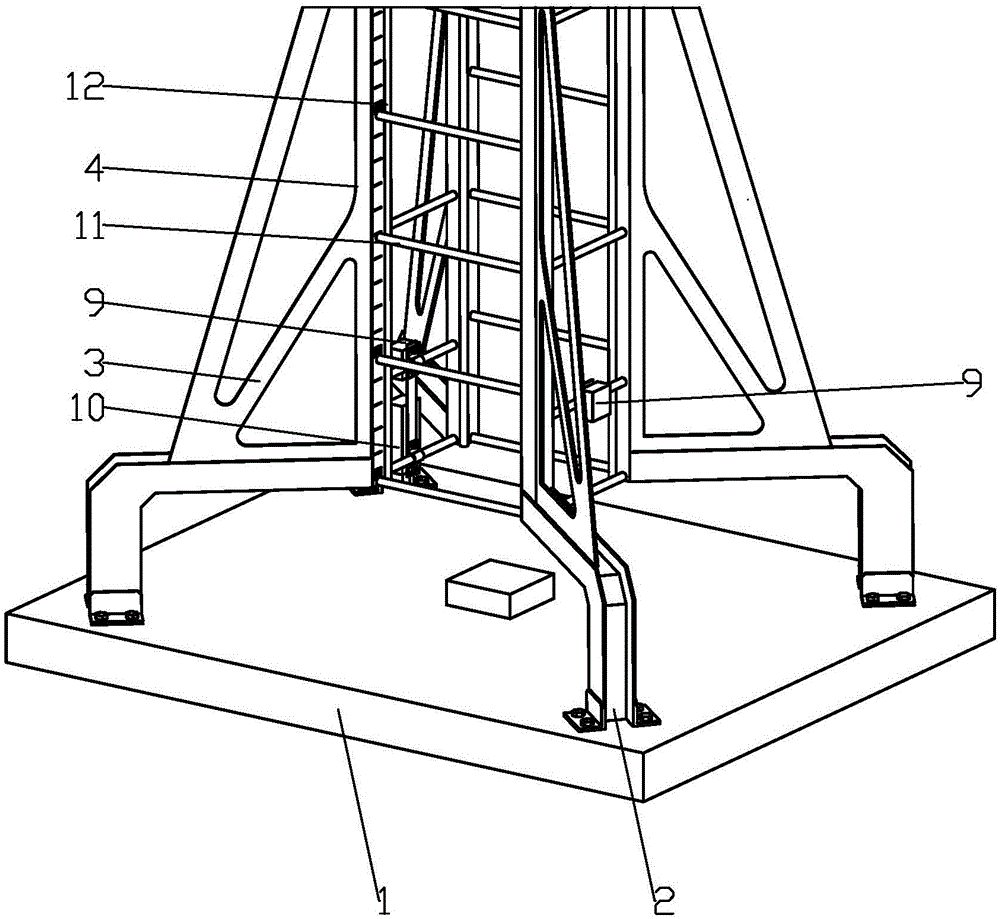

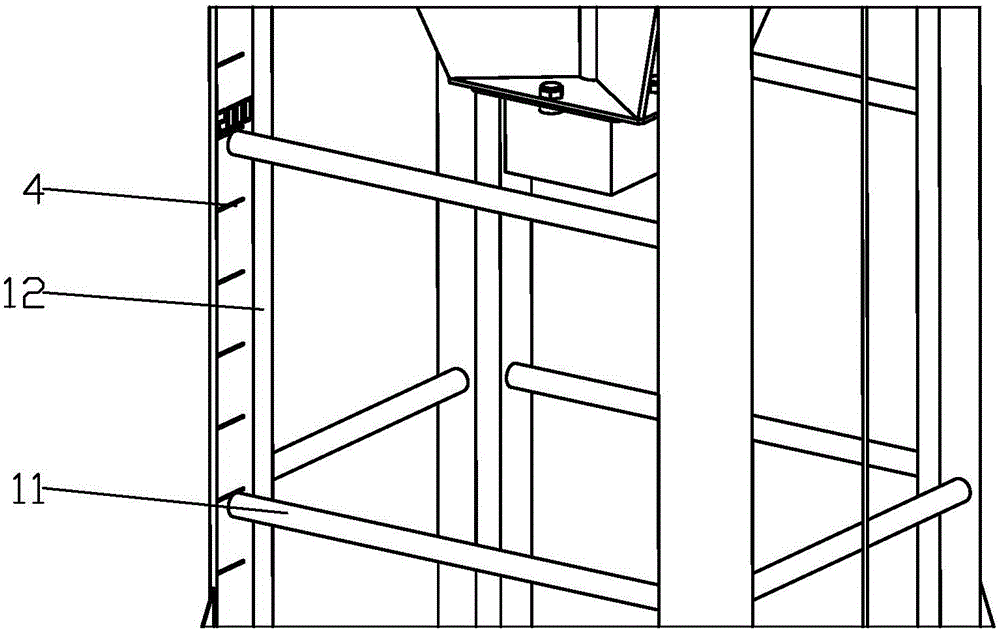

[0020] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0021] Such as Figure 1~6 As shown, the present invention mainly includes a base 1 on which four base supports 2 are connected by bolts, and the four base supports 2 are evenly distributed at the four corners of the base 1 . The front end of each base bracket 2 is connected with a guide rail bracket 4 , and every two adjacent guide rail brackets 4 are connected by a plurality of transverse connecting rods 11 , and four guide rail supports 4 are connected into a rectangular body through the transverse connecting rods 11 .

[0022] The base 1 is provided with a two-dimensional coordinate line, and the origin of the two-dimensional coordinate line is set directly below the punch assembly 5 .

[0023] The space (length, width, height) between the base bracket 2 and the base 1 should be large enough to meet the structural impact test requirements of certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com