Point contact type rectifier diode

A rectifier diode and point contact technology, applied in electrical components, electric solid devices, circuits, etc., can solve the problems of affecting the service life of the diode, unstable welding, and easy insertion of pins too deep.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

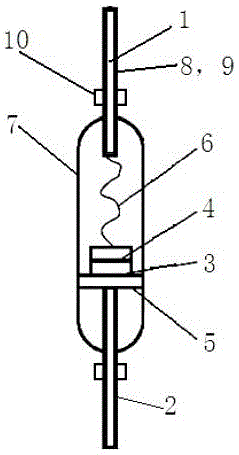

[0016] like figure 1 As shown, the point-contact rectifier diode of the present invention includes an anode lead (1), a cathode lead (2), a PN junction (3), an N-type germanium sheet (4), a bracket (5), and a metal contact wire (6) and the shell (7), the anode lead (1) and the N-type germanium sheet (4) are connected to both ends of the metal contact wire (6), and the N-type germanium sheet (4) is connected to the bracket (5) At both ends of the PN junction (3), the cathode lead (2) is connected to the support (5), the PN junction (3), the N-type germanium sheet (4), the support (5) and the metal contact wire (6) Both are arranged in the casing (7), and the outside of the anode lead (1) and the cathode lead (2) are sequentially covered with an adhesive layer (8) and a copper-nickel alloy layer (9). The anode lead (1) and the cathode lead (2) are provided with positioning blocks (10).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com