Olefin polymerization process with continuous discharging

A process, polymer technology, applied in the field of olefin polymerization processes with continuous discharge, can solve the problems of insufficient reliability and lack of flexibility, and achieve the effect of improving efficiency, reducing complexity, and avoiding polymer stagnation

Active Publication Date: 2015-10-28

TOTAL RES & TECH FELUY

View PDF14 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] However, the above equipment and processes have the disadvantage that the suspension discharged from the reactor still contains a large amount of diluent and a large amount of other reactants such as monomers, which must then be separated from the polymer particles and treated to remove them. used in the reactor

Another disadvantage of the above-mentioned equipment and processes is their lack of flexibility in terms of phase or reaction start-up or in response to large disruptions in the normal behavior of the reactor (such as a sudden interruption of one of the feed streams)

Furthermore, the reliability of the discharge of polymer slurry from the loop reactor is not high enough

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

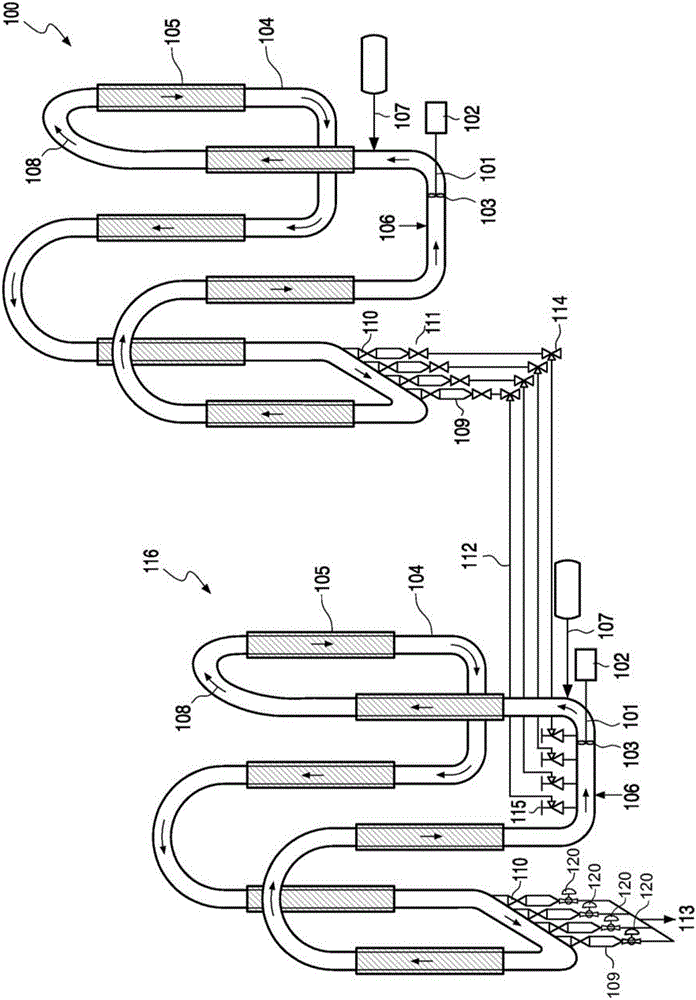

[0165] Ethylene-hexene copolymers were produced in the presence of Ziegler-Natta catalysts in double loop reactors in which the discharge portion of the second reactor had various configurations. The results are summarized in the table below:

[0166]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to a process for the preparation of a polyolefin in at least one slurry loop reactor provided with one or more settling legs, comprising the steps of: - introducing into said loop reactor one or more olefin reactants, diluents, polymerization catalyst and optional ingredients and while circulating said olefin reactants, diluents and polymerization catalyst in said loop reactor; - polymerizing said one or more olefin reactants to produce a polymer slurry comprising liquid diluent and solid olefin polyolefin particles; - continuously withdrawing polyolefin slurry comprising polyolefin particles and diluent from said reactor, via said one or more settling legs and transferring said withdrawn solid olefin polymer particles from said loop reactor to a recovery section; wherein each settling leg has an inlet connected to the reactor and an outlet connected to the recovery section, and wherein at least one settling leg is continuously open allowing continuous withdrawal of said polyolefin slurry from said loop reactor, and wherein each outlet of said one or more settling legs is connected to the recovery section by means of at least one conduit provided with a pressure control device, and wherein the pressure in said loop reactor is controlled by operating said pressure control device.

Description

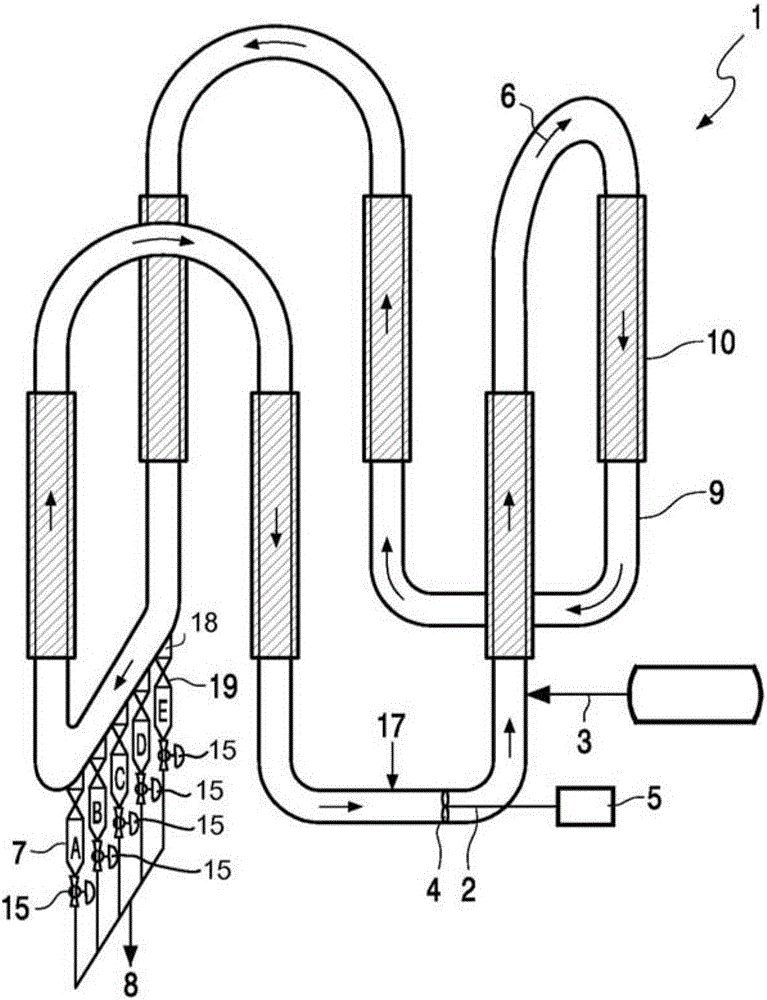

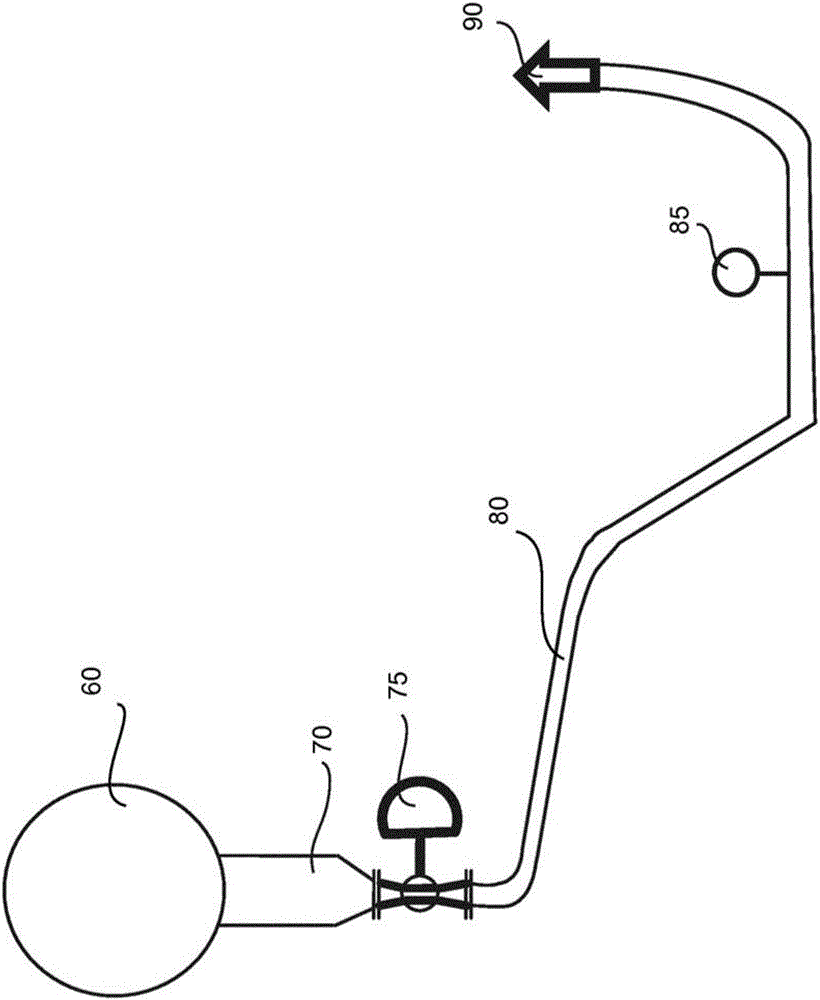

technical field [0001] The present invention relates to improvements in the removal of polymer slurry from reactors for the slurry polymerization of olefins. Background technique [0002] Olefin polymerisation, such as ethylene polymerisation, is often carried out in a loop reactor using monomer, diluent and optionally catalyst and optionally comonomer. The polymerisation is usually carried out under slurry conditions, where the product usually consists of solid particles suspended in a diluent. The slurry contents of the reactor are continuously circulated by pumps to maintain an efficient suspension of polymer solid particles in the liquid diluent and the product is often taken off for product recovery by settling legs, usually operating on a batch principle. The settling in the settling legs is utilized to increase the solids concentration of the slurry which is finally recovered as product slurry. The product is further sent to another reactor or discharged through a f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F10/00C08F2/14C08F2/01

CPCC08F210/16C08F2/14C08F210/14C08F2/01

Inventor L.福阿格A.霍雷G.诺韦莱特斯R.坦赫J.詹森斯S.比克莱斯M.里切特P.怀尔德里安

Owner TOTAL RES & TECH FELUY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com