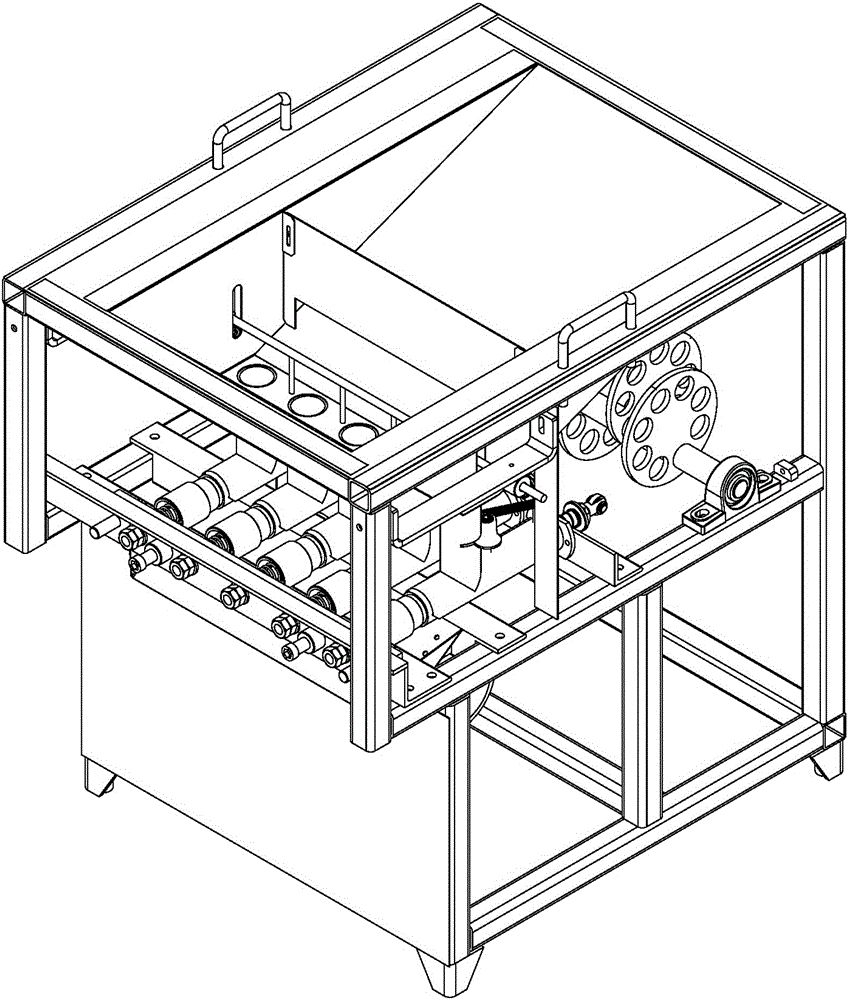

Laser circumferential cutting type hickory nut shell crushing machine

A pecan and shell breaking machine technology, applied in the direction of shelling, pod removal, food science, etc., can solve the problems of low shell breaking quality, affecting shell breaking efficiency, shell breaking, etc., and achieve good shell breaking quality and shell breaking. The effect of high success rate and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In this embodiment, the structure of the present invention is described in detail with reference to the drawings.

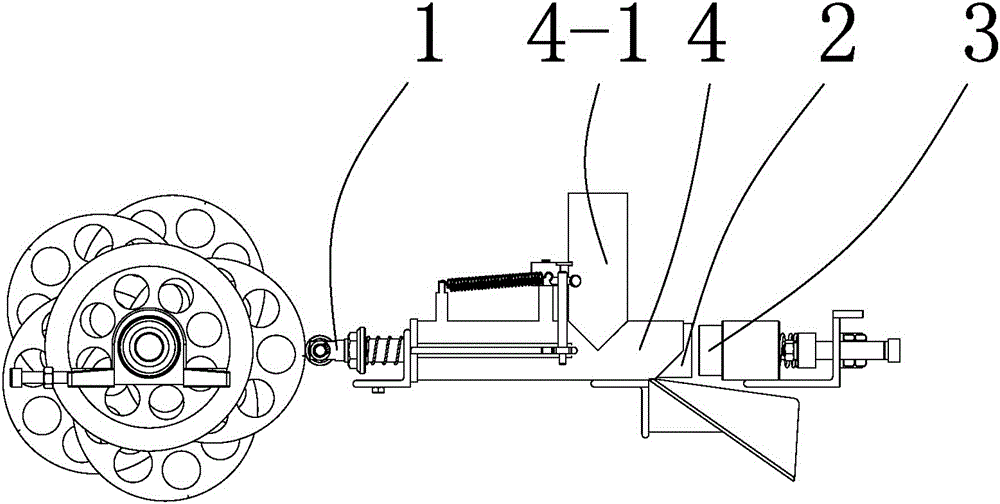

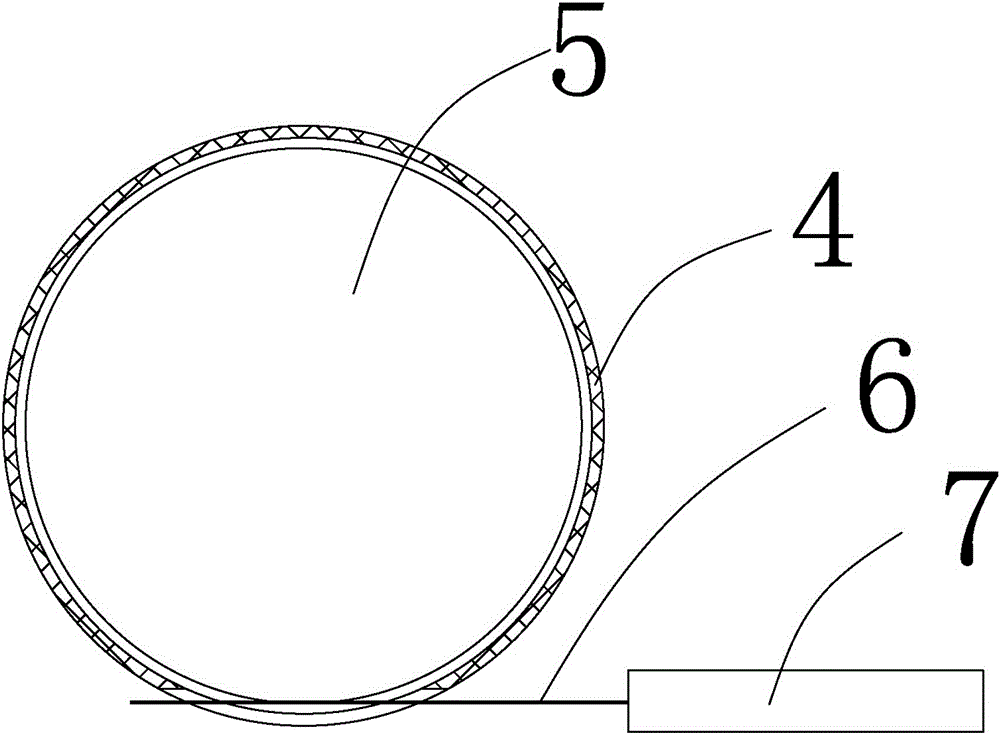

[0019] As shown in the figure, the laser circumferential cutting type hickory cracker provided by the present invention includes a frame and a gun barrel, and the gun barrel includes a T-shaped connected vertical drop tube 4-1 and a horizontal extruder. Pressure tube 4, the horizontal extrusion tube 4 is provided with a reciprocating gun shaft 1, the gun shaft 1 is provided with a shell breaking cutter head 2, the front of the shell breaking knife head 2 is provided with an extrusion rod 3, and the horizontal extrusion tube 4 The bottom is evenly distributed with gaps 8 and rolling components that make the hickory roll over. The bottom of the horizontal extrusion tube 4 is provided with gaps 8, and one side of the horizontal extrusion tube 4 is provided with a laser generator 7 facing the gaps 8. The laser light knife 6 emitted by the device 7 passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com