Resonant-type two-channel vibrating screen

A vibrating screen, dual-channel technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of high rigidity requirements of foundation and steel structure, large specifications of pipes and plates, inconvenient maintenance, etc., and achieves significant energy saving effect. , The effect of convenient screen accessories and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

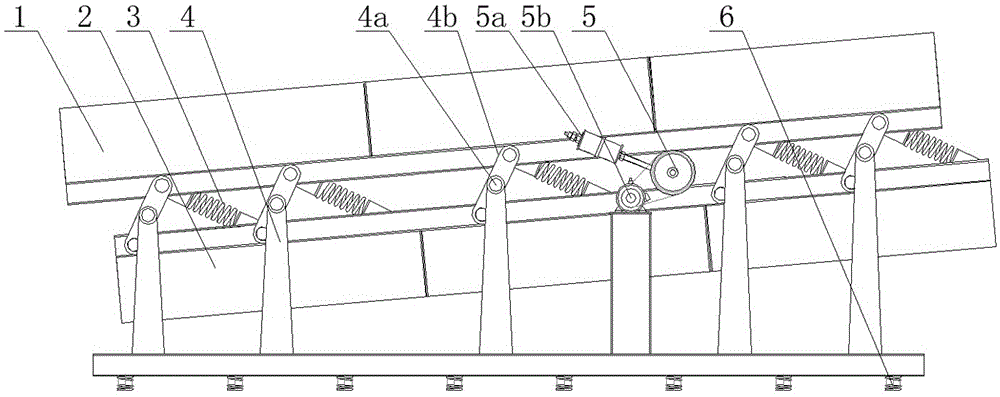

[0013] A kind of resonant dual-channel vibrating screen of the present invention, such as figure 1 As shown, it includes upper sieve body 1 and lower sieve body 2. Compared with traditional large-scale single-mass vibrating screening equipment, it has low energy consumption, light weight of the whole machine, high screening efficiency, large screening area, and convenient maintenance. , the advantage of little impact on the foundation vibration.

[0014] The present invention adopts elastic drive, resonance vibration system, such as figure 1 As shown, the upper sieve body 1 is located parallel above the lower sieve body 2, and the vibrating two-mass adopts a fully balanced upper and lower structure. On the rotating shaft 4a of the body support 4, the resonance spring 3 is connected between the lower bottom of the upper screen body 1 and the lower screen bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com