Technology method of overall forming of large curved surface composite material tool steel plate

A composite material, steel plate technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of inaccurate steel plate forming accuracy, inability to standardize, inaccurate forming accuracy, etc., to avoid mechanical equipment travel and worker skills. Dependence, reduce work intensity and safety hazards, improve the qualified rate of finished products and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] 1. A method for integral forming of a large-scale curved surface composite tooling steel plate, the steps of which are:

[0029] 1) According to the size of the overall steel plate used in the composite material tooling, the material is blanked, and the processing amount of one side is 20mm.

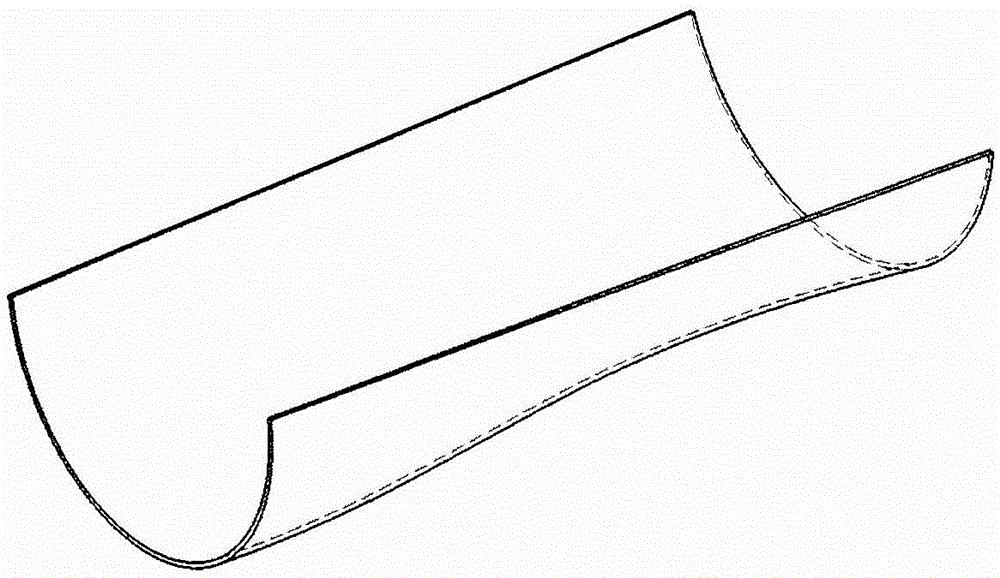

[0030] 2) Preforming: According to the minimum curvature of the overall steel plate, it is rolled into an arc-shaped steel plate.

[0031] 3) Heat treatment to remove stress, and then use vibration to remove residual stress and heat treat oxidation products.

[0032] 4) Manually remove the oxidation products on the stubborn tooling preforming surface to ensure that the preforming surface is smooth and free of impurities.

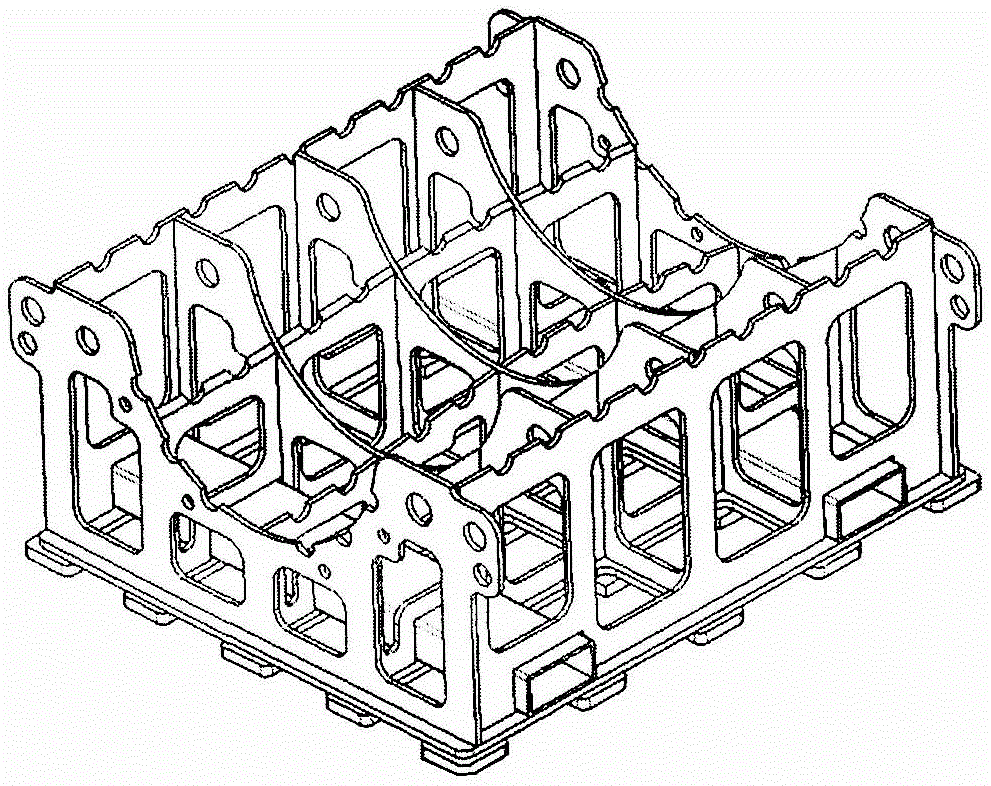

[0033] 5) Put the curved steel plate after roll bending and stress relief on the support frame of the tooling. The support frame is as follows: figure 1 As shown, the two sides of the curved steel plate are sealed with a steel plate with a thickness of 40mm an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com