Anti-swing control method for crane

A control method and technology of cranes, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of increasing response rise time and reducing operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing of description, the present invention will be further described.

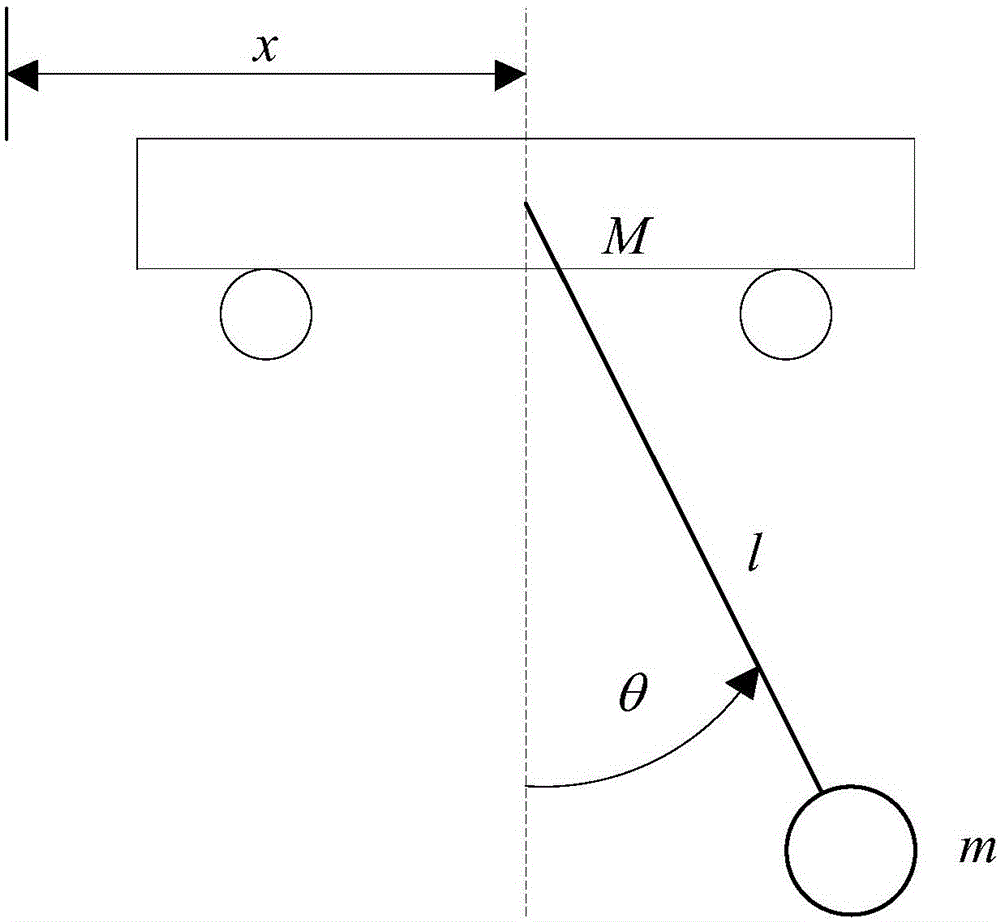

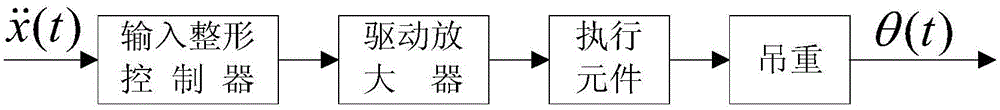

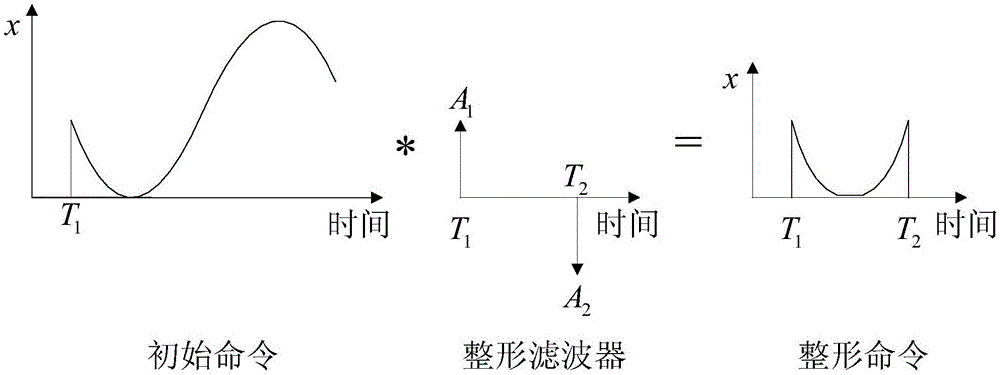

[0033] like figure 1 As shown, the trolley runs horizontally along the boom, x(t) is the displacement of the trolley, l is the length of the wire rope, m is the mass of the hoist, θ(t) is the swing angle of the hoist; the mathematic model of the hoist swing of the crane is adopted B for in is the damping ratio, ω n is the natural frequency of hoisting swing, t is the acceleration time; when the damping ratio The mathematical model of hoisting swing can be simplified as according to in is the acceleration; and the natural frequency of the hoisting swing inferred And then come to θ · · ( t ) + ω n 2 θ ( t ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com