Dry quenching primary deduster fragment hoisting method

A piece-by-piece hoisting and deduster technology, which is applied in coke ovens, coke cooling, furnace prevention/removal of fouling, etc., can solve the problems of inconvenient installation, complicated installation process, and high installation cost of CDQ primary dust collectors, and achieve Reduce the time of high-altitude operations and safety risks of high-altitude operations, the effect of fast construction progress and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The coke CDQ primary deduster fragmentation hoisting method of the present invention is characterized in that it comprises the following steps:

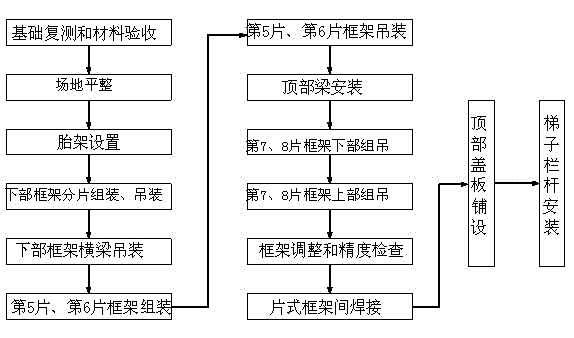

[0070] figure 1 It is a block diagram of the piecewise hoisting process of the CDQ primary dust collector according to the embodiment of the present invention.

[0071] a. Preparatory measures for hoisting, including the following steps:

[0072] (1) Basic retest

[0073] Retest the longitudinal and transverse centerlines and elevation of the primary dust removal foundation according to the relevant specifications, and check the appearance quality and positioning dimensions of the anchor bolts;

[0074] (2) Acceptance of materials and semi-finished products

[0075] Before assembly, the team should carefully check and accept the semi-finished products and materials sent to the site, such as columns, beams, profiles, etc., especially requesting to check the straightness of each column, and make corrections if necessary. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com