Method used for reducing oxygen content of czochralski silicon

A technology of Czochralski single crystal and oxygen content, which is applied in the directions of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of difficulty in manufacturing silicon nitride crucibles, increase in manufacturing cost, and influence on the quality of single crystals, etc. Achieving the effect of low cost, less investment and lower oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

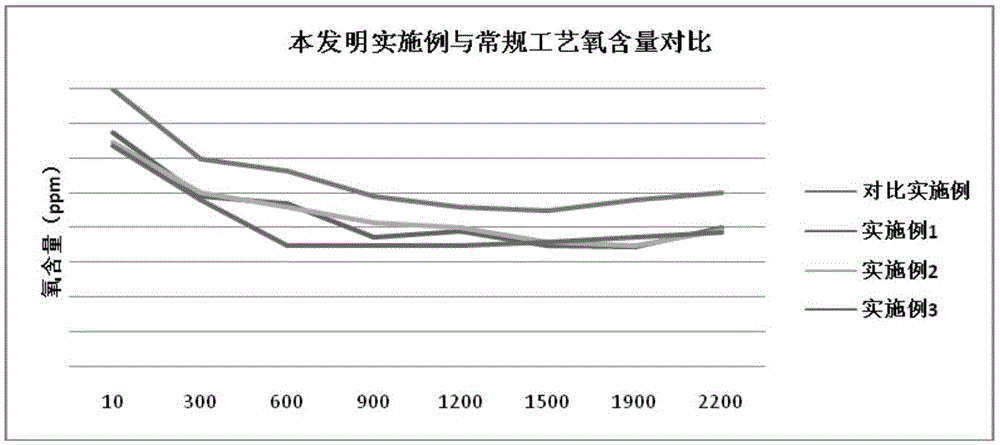

Embodiment 1

[0016] The method includes adjusting and changing the power of the auxiliary heater at the bottom, the rotating speed of the crucible, the flow of argon gas and the furnace pressure during the crystal pulling process. It is characterized in that: the power of the bottom auxiliary heater is reduced from 30-35kw to 15-20kw when the temperature is stable, and does not change when it is gradually reduced to 5kw in the later stage of equal diameter; the rotation speed of the crucible is instantaneous when it enters equal diameter Reduce 2-3r revolutions, and slowly decrease in the later stage of the equal diameter; use low furnace pressure to stabilize the temperature, the furnace pressure gradually increases at the equal diameter head, and the argon flow rate gradually decreases at the equal diameter head.

[0017] The adjustment and change of the power of the bottom auxiliary heater means that when the temperature is stable, the power of the bottom auxiliary heater is reduced from...

Embodiment 2

[0022] The method includes adjusting and changing the power of the auxiliary heater at the bottom, the rotating speed of the crucible, the adjusting and changing of the argon gas flow and the furnace pressure during the crystal pulling process. The specific implementation process is as follows:

[0023] The adjustment and change of the power of the bottom auxiliary heater means that when the temperature is stable, the power of the bottom auxiliary heater is reduced from 35kw when the material is formed to 20kw in an instant, and the power of the bottom auxiliary heater remains unchanged during the process of seeding, shouldering, and turning. , the power of the auxiliary heater at the bottom is reduced to 5kw at the speed of 2kw / h when the equal-diameter leftover material is 60kg, and it does not change until the end of the crucible. The power change process of the bottom auxiliary heater is accompanied by the automatic adjustment of the power of the main heater.

[0024] The...

Embodiment 3

[0028] The method includes adjusting and changing the power of the auxiliary heater at the bottom, the rotating speed of the crucible, the adjusting and changing of the argon gas flow and the furnace pressure during the crystal pulling process. The specific implementation process is as follows:

[0029] The adjustment and change of the power of the bottom auxiliary heater means that when the temperature is stable, the power of the bottom auxiliary heater is reduced from 30kw when the material is formed to 15kw in an instant, and the power of the bottom auxiliary heater remains unchanged during the process of seeding, shouldering, and turning. . When the equal-diameter remaining material is 50kg, the power of the bottom auxiliary heater is reduced to 5kw at a speed of 2kw / h, and does not change until the end of the finishing. The power change process of the bottom auxiliary heater is accompanied by the automatic adjustment of the power of the main heater.

[0030] The adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com