Method and device for automatically and intelligently piecing ring-spun yarn broken ends

A jointing method and automatic technology, which is applied to jointing devices, spinning machines, textiles and papermaking, etc., can solve the problems of many people in production, rising labor costs, and low profitability of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

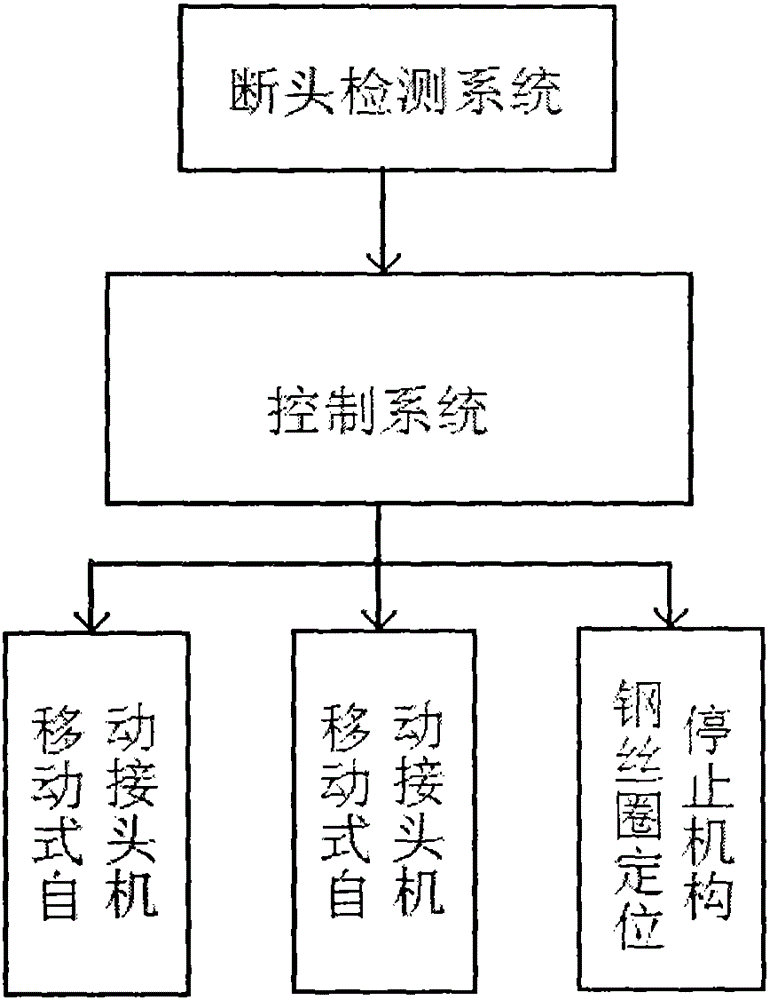

[0079] like figure 1 As shown, the device used for the automatic intelligent splicing method of ring spun yarn breakage in the present invention is composed of a broken end detection system, a mobile automatic splicing machine, a traveler positioning stop mechanism, a single-chip microcomputer or a control system composed of a PLC, and the broken end The detection system uses sensors to detect the spinning end-breakage signal of each single spindle in the whole machine in real time. The single-chip microcomputer or PLC control system receives the end-breakage detection system signal, and after program processing, sends out the end-breakage signal to the mobile automatic jointing machine and the traveler positioning stop mechanism. .

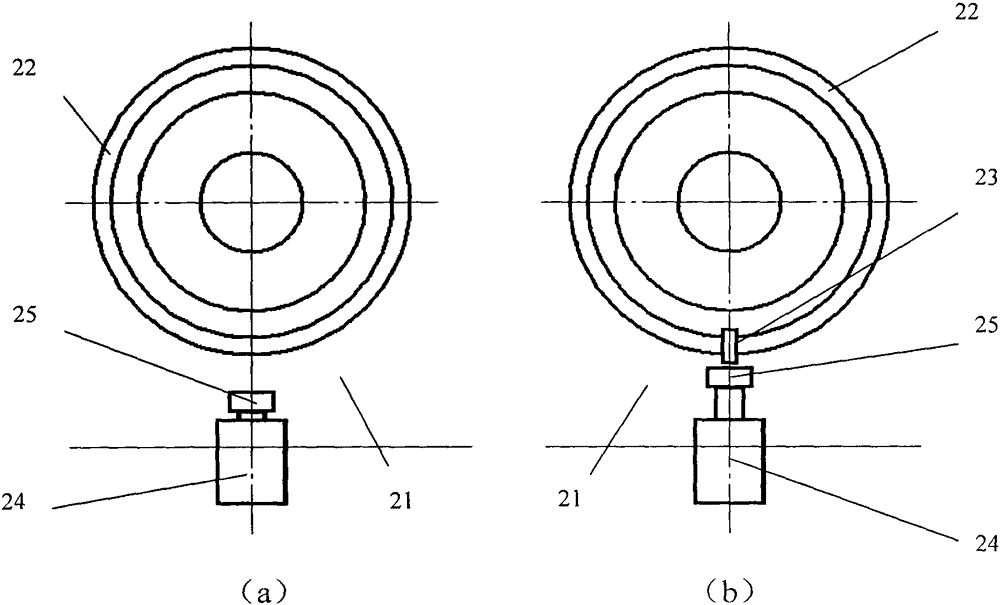

[0080] like figure 2 (a), figure 2 As shown in (b), the ring plate 21 has a ring ring 22 and a traveler 23. The traveler positioning stop mechanism is mainly composed of an electromagnet 24 and a magnet 25. The magnet 25 is installed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com