High-precision spindle of braiding machine

A knitting machine, high-precision technology, applied in woven fabrics, textiles and papermaking, etc., can solve the problems affecting product quality and production efficiency, cannot be adjusted steplessly, and the pay-off is not stable, so as to improve product quality and work efficiency, The effect of wide adjustment range and uniform payout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

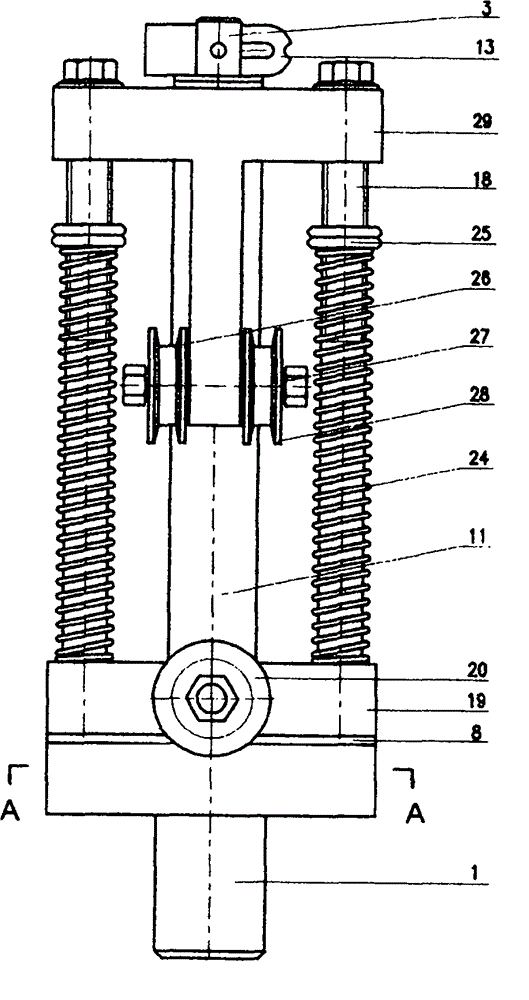

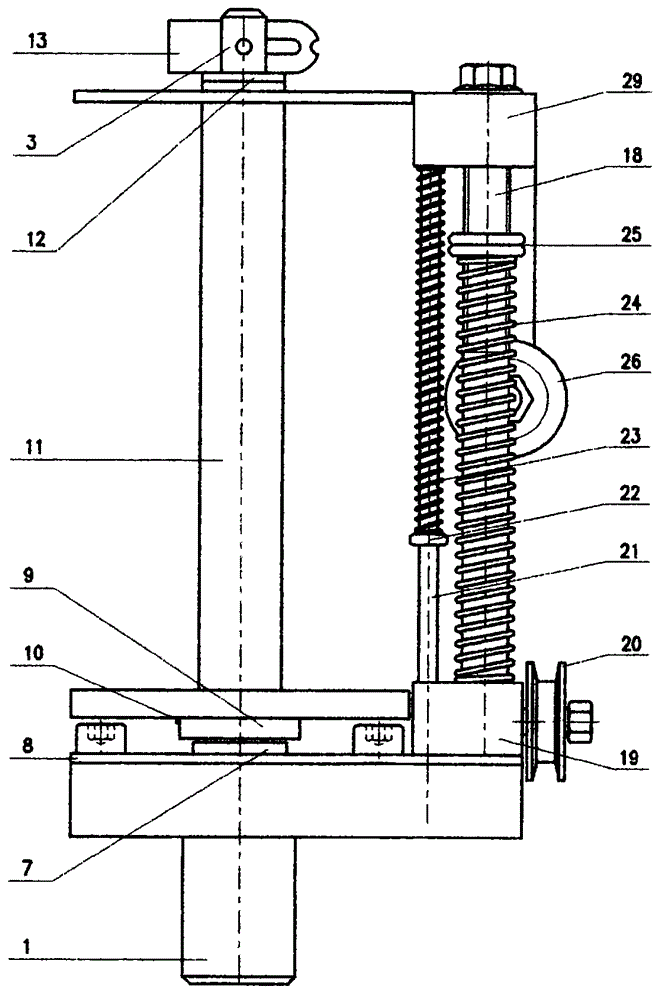

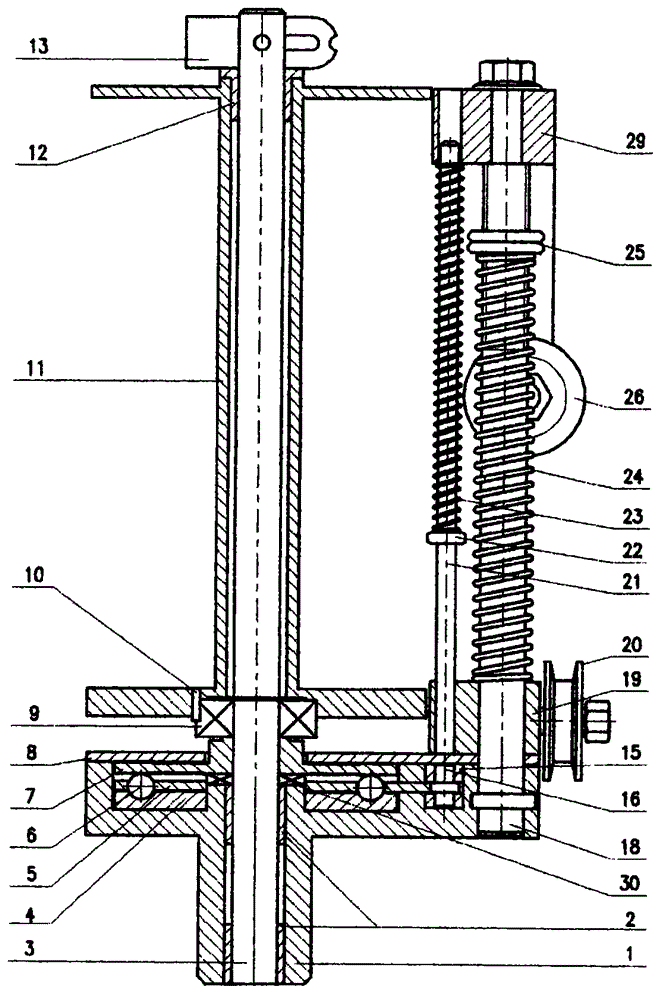

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 As shown, the present invention includes a spindle base 1, a needle bearing 2, a bobbin column 3, a cam disc 4, a ball dial 5, a ball 6, a friction disc 7, a friction cover plate 8, a one-way bearing 9, a pin shaft 10, Loading bobbin 11, nylon sleeve 12, shaft retaining plate 13, wedge 14, shift fork slider 15, shift fork shaft 16, shift fork spring 17, guide post 18, slide seat 19, movable pulley 20, slide rod 21, limit Block 22, back-moving spring 23, tension spring 24, tension adjustment nut 25, output wheel 26, wire crossing wheel shaft 27, guide wheel 28, holder 29 and plane bearing 30.

[0022] exist figure 1 , figure 2 , image 3 , Figure 4 , Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com