Flame-retarding composite floor leather resisting abrasion and skid and manufacturing technology and application thereof

A manufacturing process and floor leather technology, which is applied in flame-retardant, wear-resistant and non-slip composite floor leather and its manufacturing process and application fields, can solve the problems of not considering wear resistance and aging resistance, unsuitable floor leather, poor flame retardancy, etc. problem, to achieve the effect of excellent light aging performance, good anti-skid performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

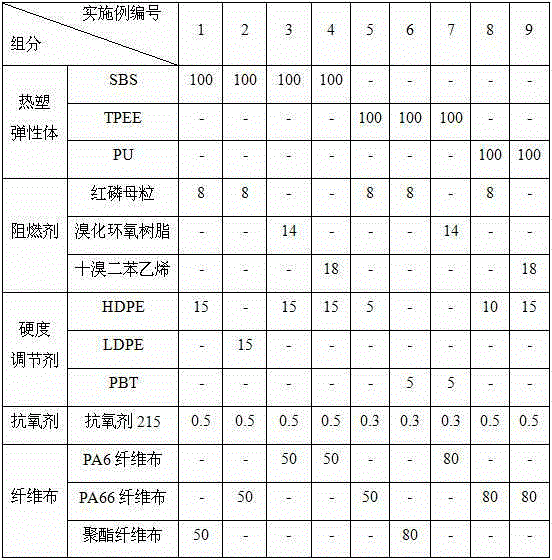

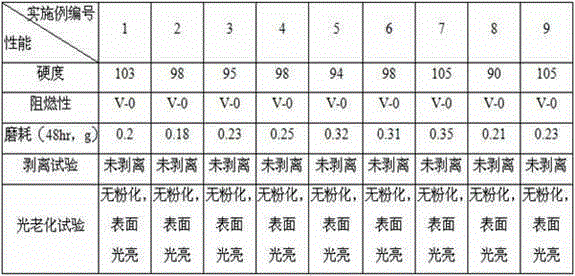

[0027] Embodiments 1 to 9 of the present invention are made of flame-retardant, wear-resistant and anti-slip composite floor leather, which are composed of fiber cloth as the skeleton material and flame-retardant thermoplastic elastomer material as the surface glue. Parts by weight are shown in Table 1:

[0028] Table 1 Components and parts by weight of flame-retardant, wear-resistant and non-slip composite floor leather in Examples 1-9

[0029]

[0030] Note: "-" in the table means not added.

[0031] Manufacturing process:

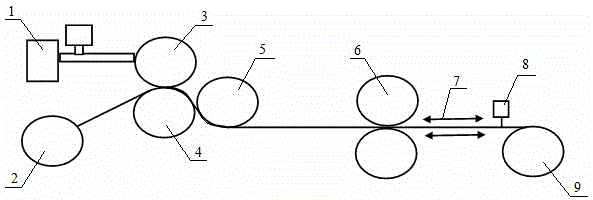

[0032] Such as figure 1 As shown, according to Table 1, the thermoplastic elastomer, flame retardant, hardness regulator and antioxidant were blended in the twin-screw extruder 1, and the fiber cloth wound on the base cloth roll 2 was stretched and fixed on the upper bonding Between the heating guide roll 3, the lower adhesive heating guide roll 4 and the right adhesive heating guide roll 5, the twin-screw extruder 1 winds the upper adhesive heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com