High efficient installation construction method for rowed cable boxes in hollow brick filled wall

A cable box and filling wall technology, which is applied in the field of efficient installation and construction method of hollow brick filling wall into a cable box, can solve the problems of low construction efficiency, line box displacement, difficulty in ensuring levelness, etc., and achieve labor cost reduction and consumption Save time and improve construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

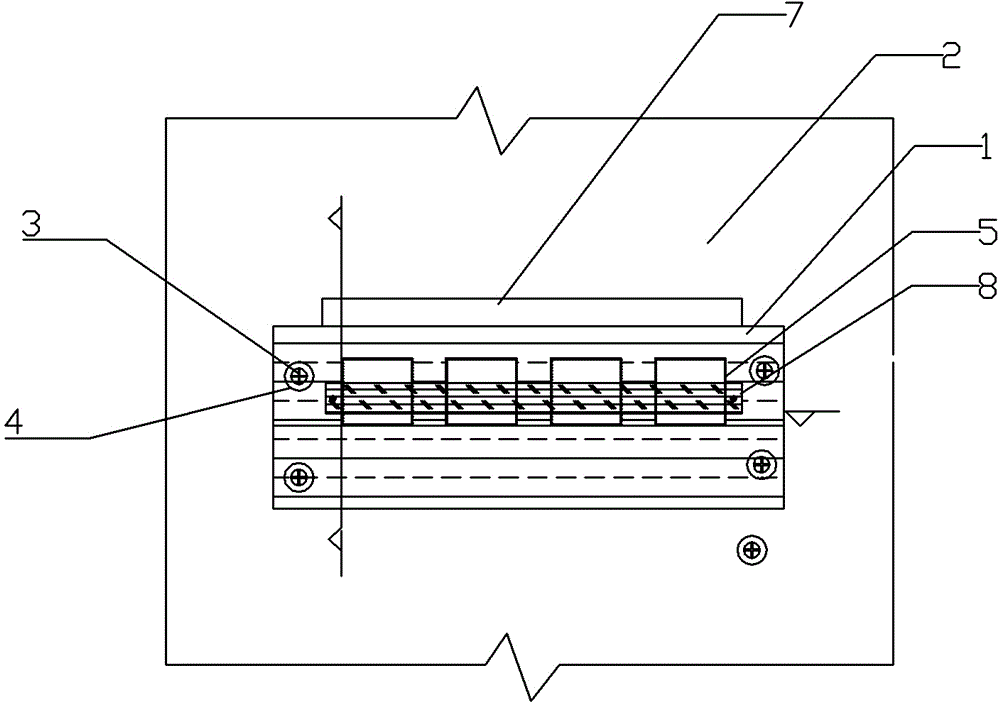

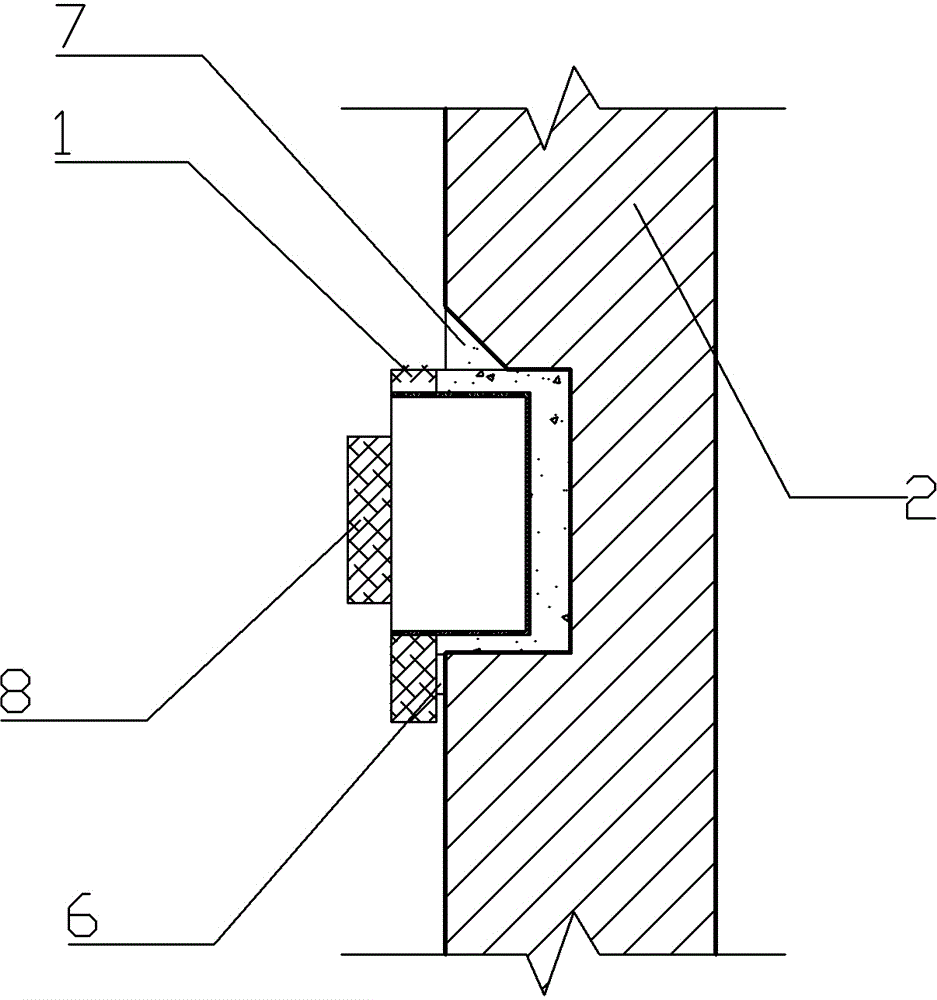

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

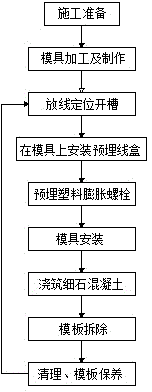

[0025] Such as figure 1 The construction method for the efficient installation of the hollow brick filled wall into the wiring box shown includes the following steps:

[0026] a. Construction preparation

[0027] The construction preparation is first to be familiar with the construction drawings, to determine the specifications and quantities of the line boxes installed in rows of strong and weak currents such as sockets and switches in the wall, to determine the batches of cable boxes installed on each layer, to determine the mold specifications and quantities, and then to draw the mold Processing drawings, and finally prepare the materials required for the mold.

[0028] b. Mold processing and production

[0029] Process flow: blanking→scribing→cutting wire box mounting holes→drilling mold fixing holes→installing positioning bars

[...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap