A bionic adaptive pdc drill bit

A self-adaptive, drill bit technology, applied in construction and other directions, can solve the problems of delamination or even peeling, low work efficiency, fast wear of cutting teeth, etc., to achieve the effect of improving efficiency and chip removal effect, improving drilling efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

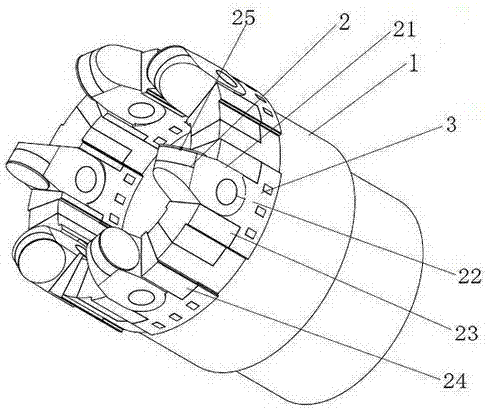

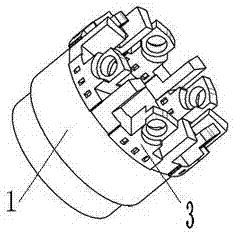

[0020] See figure 1 , figure 2 , Figure 4 with Figure 5 As shown, this embodiment is composed of a drill base 1, several cutting teeth 2 and several drill blade wings 3. The several drill wings 3 are fixedly arranged on the upper end of the drill base 1, and the several cutting teeth 2 are arranged through a pin 22. On several drill blades 3;

[0021] The polycrystalline diamond composite sheet 25 is fixedly arranged on the upper end of the cutting tooth cylinder 21 to form the cutting tooth 2. The cutting tooth cylinder 21 is hinged to the bit blade 3 through a pin 22, and the first elastic body 23 and the second elastic body 24 are respectively arranged On both sides of the cutting tooth cylinder 21 and matched with the inner wall of the bit blade 3;

[0022] The initial caster angle a of the cutting teeth 2 is 0°-30°, and the side turning angle β is 0°-15°;

[0023] The cutting tooth 2 is a superhard cutting material, which is a polycrystalline diamond composite sheet or a po...

no. 2 example

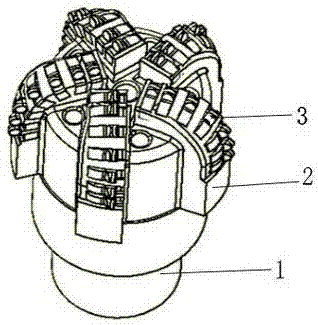

[0025] See figure 2 , image 3 , Figure 4 with Figure 5 As shown, this embodiment is composed of a drill base 1, several cutting teeth 2 and several drill blade wings 3. The several drill wings 3 are fixedly arranged on the upper end of the drill base 1, and the several cutting teeth 2 are arranged through a pin 22. On several drill blades 3;

[0026] The initial caster angle a of the cutting teeth 2 is 0°-30°, and the side turning angle β is 0°-15°;

[0027] The cutting tooth 2 is a superhard cutting material, which is a polycrystalline diamond composite sheet or a polycrystalline diamond sheet or a cemented carbide tooth.

[0028] The working principle and process of the present invention:

[0029] See figure 1 , figure 2 with image 3 As shown, the bionic prototype tiger claw bone of the present invention, when the tiger preys on its prey, its front paws can instantly penetrate the prey’s skin and flesh, but when the toe tip touches the prey’s hard bones and encounters resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com