Hard Rock Tunneling Machine Test Bench Support Steering Hydraulic System

A hard rock roadheader and steering hydraulic technology, which is applied in mechanical equipment, fluid pressure actuation devices, mining equipment, etc., can solve problems such as less research, reduce costs, improve flexibility and effectiveness, and realize support functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail with reference to the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, and are not used to limit the protection scope of the present invention.

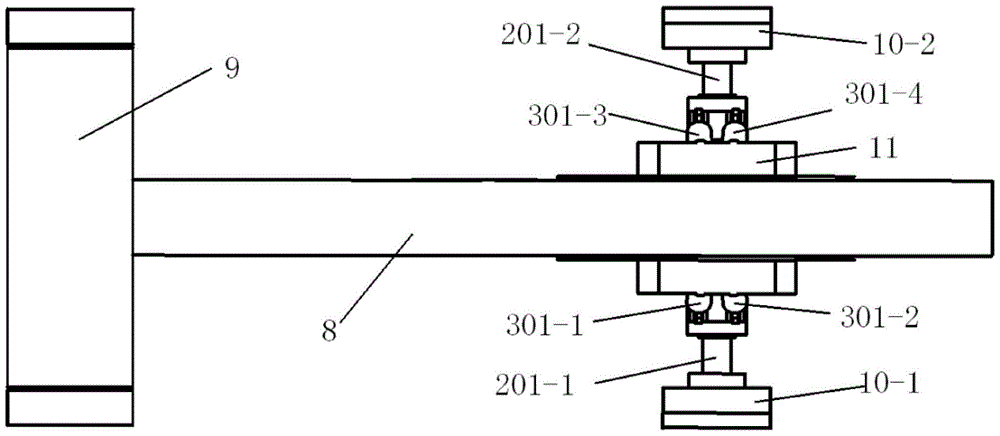

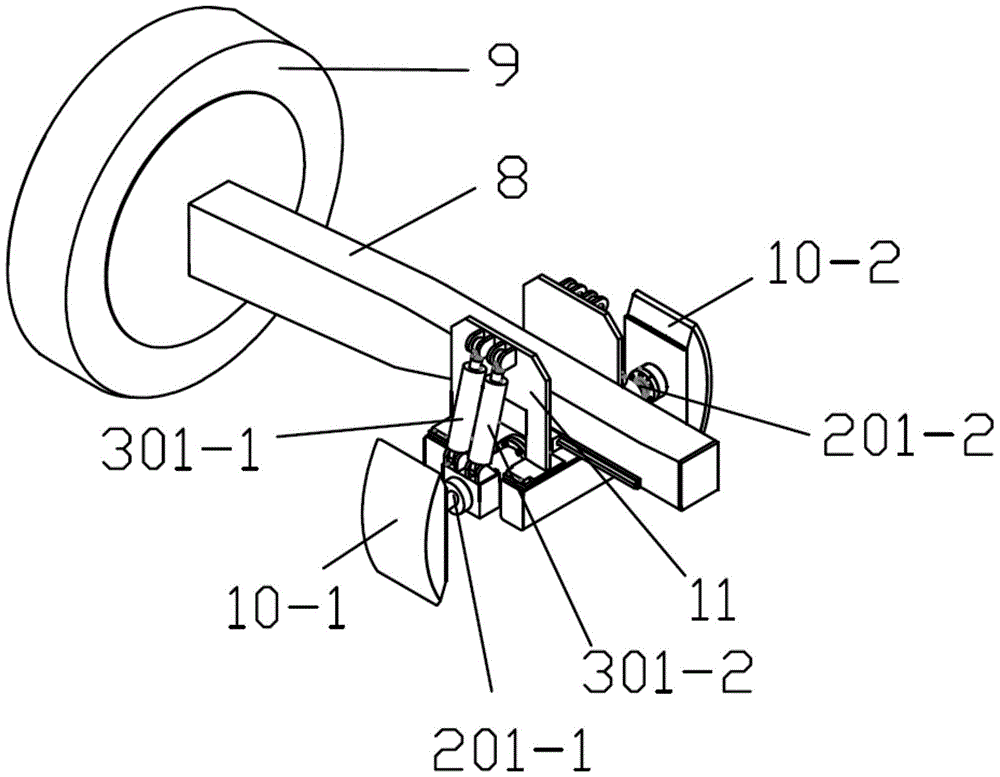

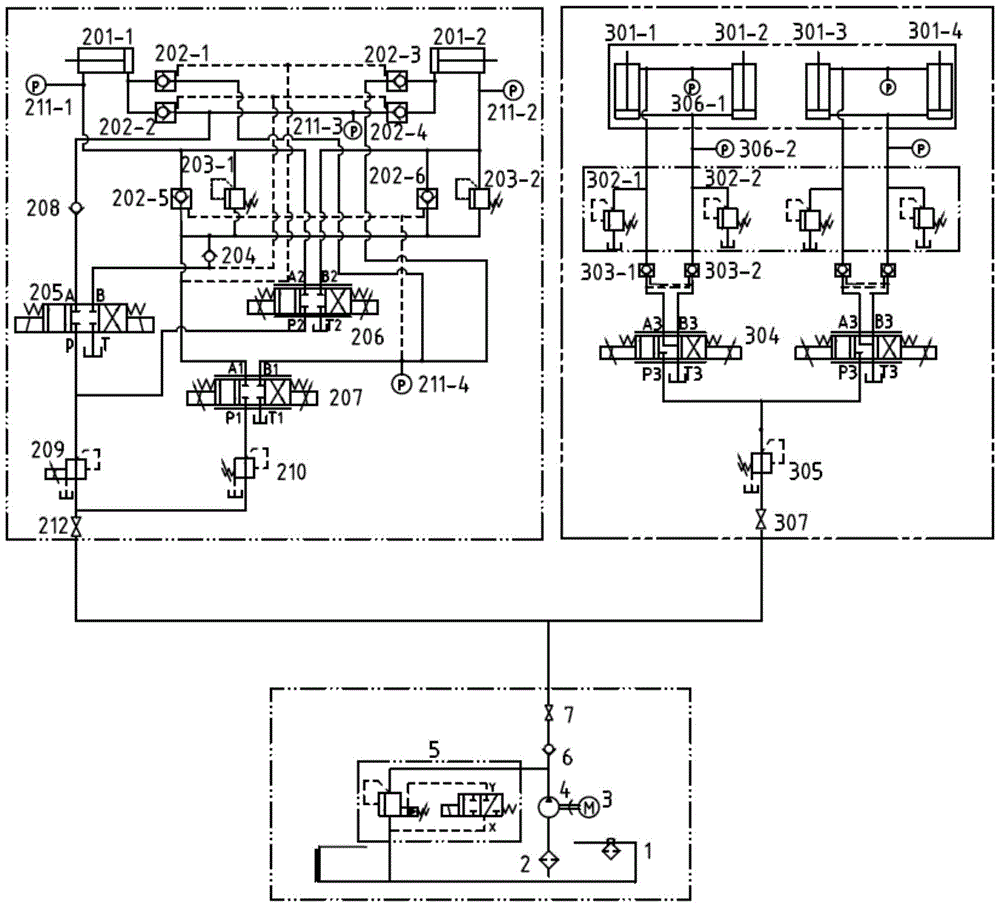

[0022] Such as figure 1 and figure 2 As shown, it is a schematic diagram of the installation and use of the supporting steering hydraulic system of the hard rock roadheader test bench of the present invention, the cutter head 9 is connected with the main beam 8; Side and located under the saddle frame 11, the cylinder rods of the first and second hydraulic cylinders 201-1, 201-2 are respectively connected with the first and second support shoes 10-1, 10-2, and the first and second hydraulic cylinders 201- 1. 201-2 are fixedly connected by two hydraulic cylinders, and the first and second hydraulic cylinders are connected to the saddle frame 11 through cross pins; there is one pitching modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com