Split internal combustion engine

A split-type internal combustion engine and combustion chamber technology, which is applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems that the internal combustion engine cannot further improve the compression ratio, the combustion temperature is difficult to control, and the internal combustion engine is harmful. Loss of energy, effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

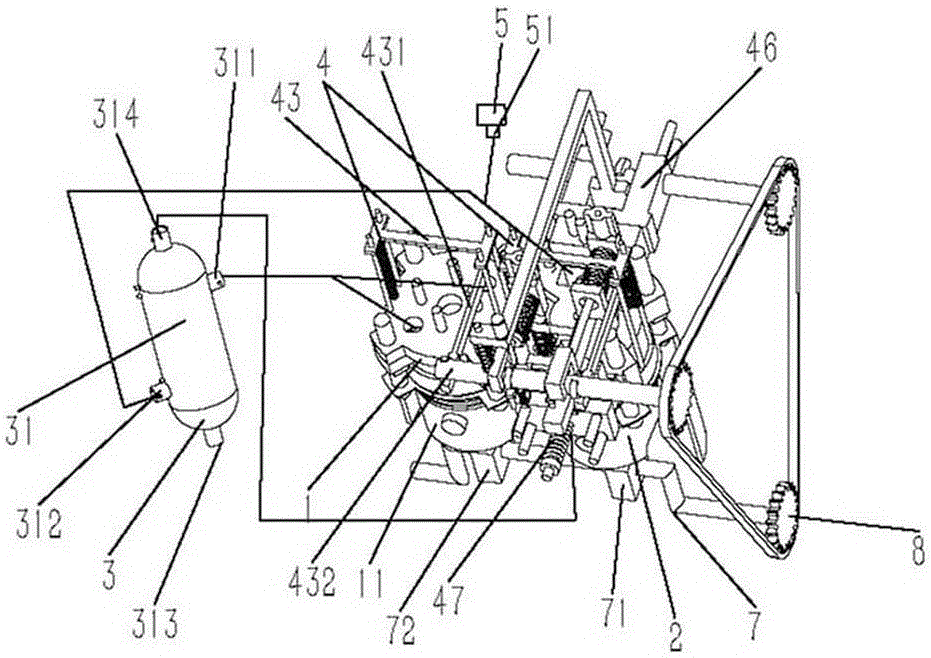

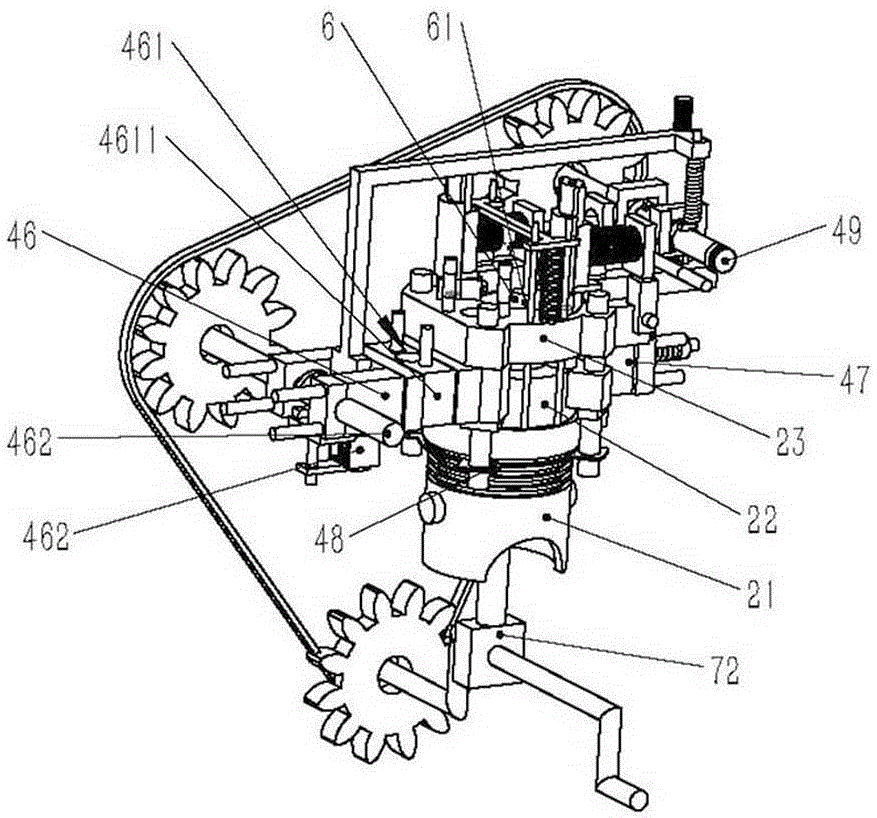

[0032] Example 1: Reference figure 1 , including the first cylinder 1, the second cylinder 2, the temperature control device 3, the valve device 4, the fuel device 5 and the ignition device 6, the first cylinder 1 is used for intake and compression strokes, and the second cylinder is used for combustion and exhaust stroke.

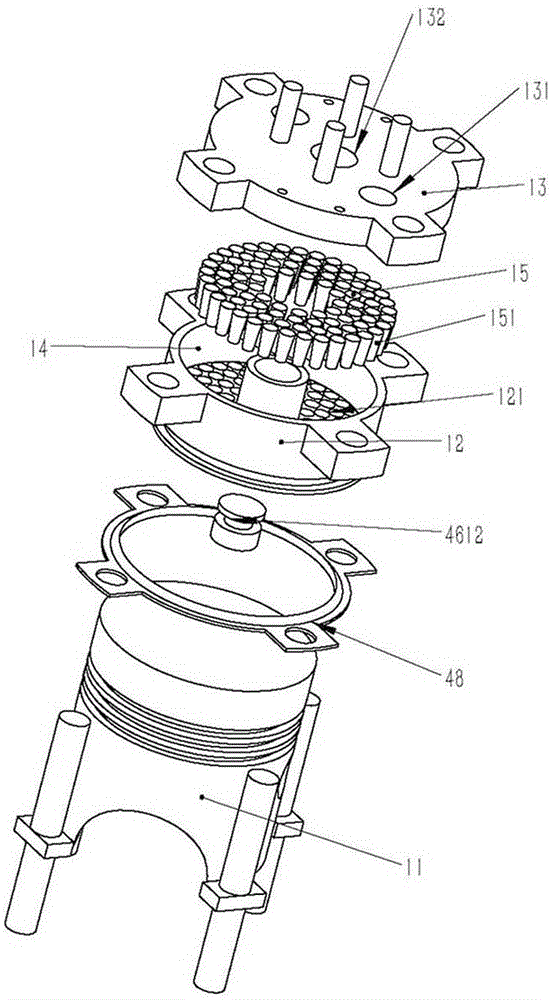

[0033] The first cylinder 1 comprises a first piston 11, a first cylinder head 12 and a first cylinder cover 13 arranged in the first cylinder, the bottom of the first cylinder head is provided with a tapered notch 121, the first cylinder head 12 and the first cylinder head The cylinder head 13 forms a gas storage chamber 14, and the gas storage chamber is provided with a check structure 15 for placing compressed gas backflow. The check structure is composed of a check plug 151 arranged in a notch. The air outlet 131 and the oil outlet 132 of the air storage chamber.

[0034] The second cylinder 2 includes a second piston 21 , a second cylinder head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com