Static levelling instrument system having automatic water supplementing and draining functions

A hydrostatic level, supplementary drainage technology, applied in the direction of hydrostatic pressure, can solve the problems of inability to read the liquid level and the amount of liquid level change normally, large resistance, hidden safety hazards, etc., to ensure the normal reading of liquid level and liquid level. The effect of bit change, improving response speed, and avoiding security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

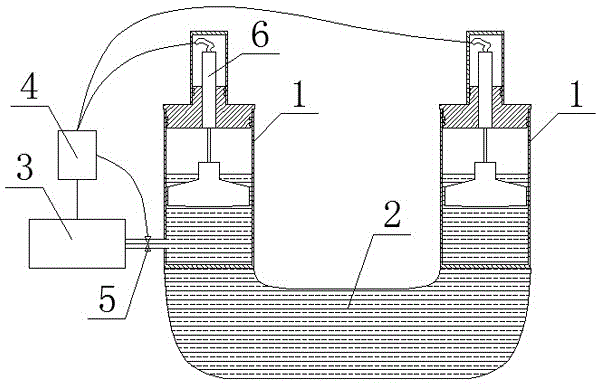

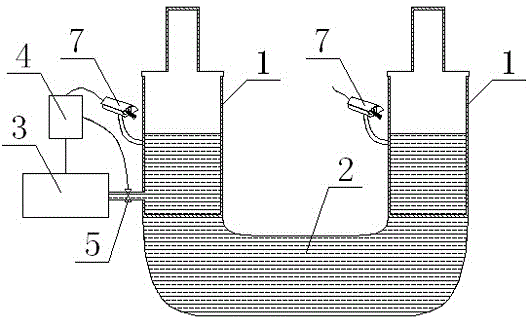

[0054] [Example 6] such as Image 6 As shown, the static level system with automatic replenishment and drainage function includes two static levels and an automatic replenishment and drainage device. The static level includes a displacement gauge 6 and a liquid storage tank 1. The displacement gauge 6 is fixedly installed in the storage tank through a mounting base. On the liquid barrel 1, the liquid storage barrels 1 of the two static levels are connected through the liquid pipe 2; diameter of. The diameter of the liquid pipe 2 is thickened, the resistance when the liquid in the liquid storage tank 1 flows into the liquid pipe 2 is greatly reduced, and at the same time, the flow rate of the liquid in the liquid pipe 2 is ensured, and the response speed of the static level system is improved , to realize the dynamic measurement.

[0055] The described automatic replenishment and drainage device comprises a water tank 3, a controller 4, a data acquisition assembly and a solen...

Embodiment 8

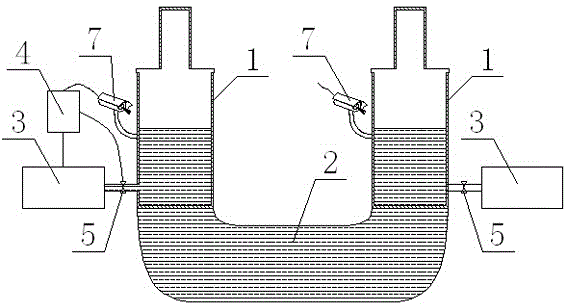

[0060] [Embodiment 8] A static level system with automatic replenishment and drainage function, including two static levels and an automatic replenishment and drainage device, the liquid storage tanks 1 of each static level are connected through the liquid pipe 2; the automatic replenishment The drainage device is used for automatically replenishing water in the liquid storage tank 1 or automatically draining the water in the liquid storage tank 1 according to the liquid level in the liquid storage tank 1 .

[0061]Such as Figure 8 As shown, the automatic replenishment and drainage device includes a water tank 3, a limit drainage hole 9 and a water supply assembly. The limit drainage hole 9 is arranged on the wall of the liquid storage tank 1, and the height of the limit drainage hole 9 is determined according to the range of the static level. It is determined that the limit drain hole 9 is connected to the water tank 3 through a drain pipe, and when the liquid level in the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com