Optical fiber gyroscope with optical fiber ring adopting double-ring design

A fiber-optic gyroscope and fiber-optic ring technology, which is applied in Sagnac effect gyroscopes, gyroscopes/steering sensing devices, measuring devices, etc., can solve problems such as unsatisfactory results, unusable use, and large data volume, and achieves a solution to the problem. Temperature distribution symmetry problem, the effect of solving temperature drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] The purpose of the present invention is to provide a fiber optic gyro device with better temperature stability and suitable for mass production.

[0018] The purpose of the present invention is achieved like this:

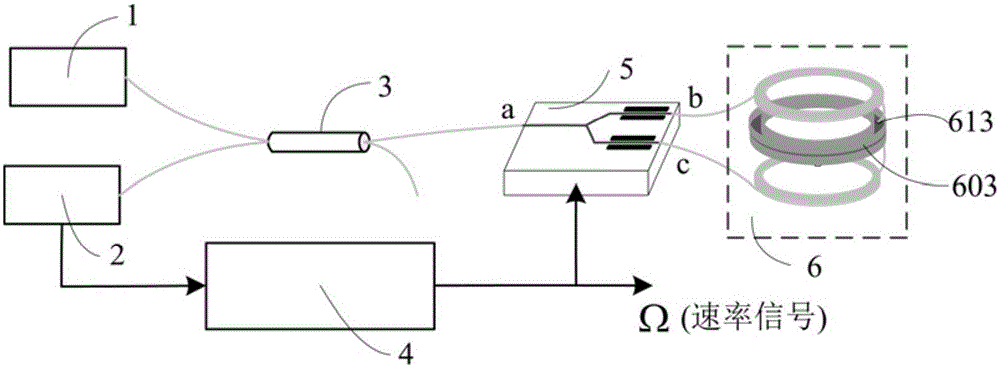

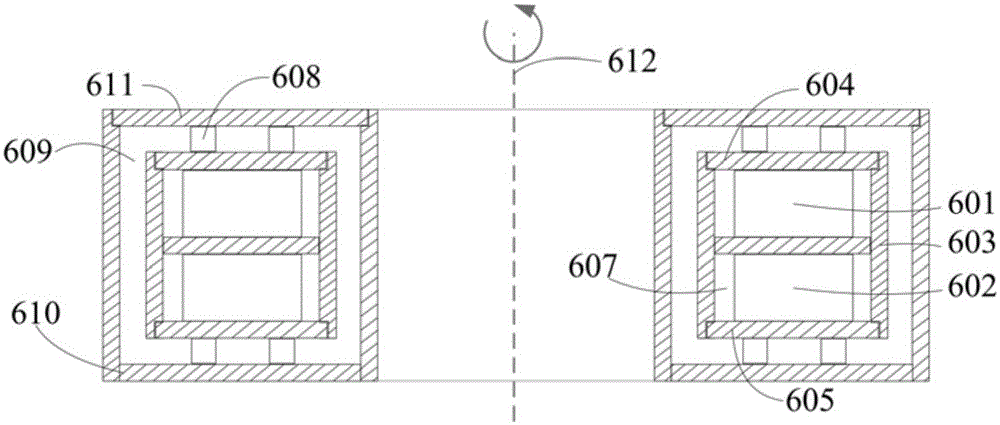

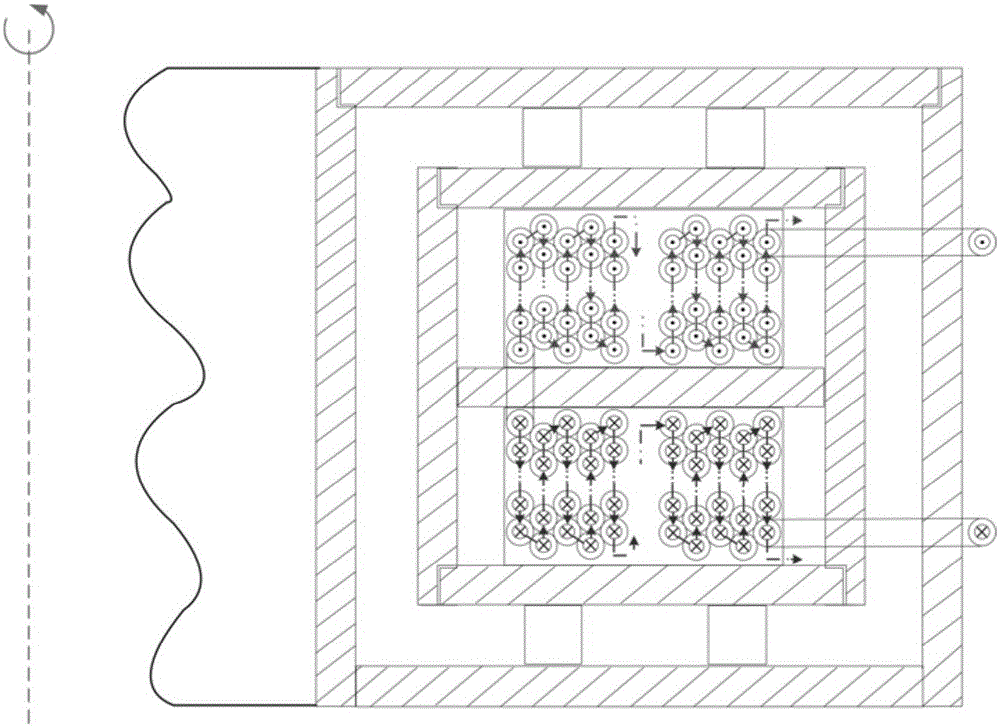

[0019] It includes a light source 1 connected by connecting optical fibers, a photoelectric detector 2, a polarization-maintaining fiber coupler 3, an all-digital closed-loop processing circuit 4, and an optical modulator 5. It also includes a pair of optical fiber rings and a matching heat insulation device. The interference component 6. The assembly method of the interference component is to take two identical optical fiber rings 601 and 602 and place them in two back-to-back heat conduction grooves 603 respectively, and one of the rings is turned 180° to ensure that each ring of the two optical fiber rings is symmetrical to each other. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com