A spectrophotometric water quality automatic testing process

A spectrophotometry and automatic test technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of large measurement error, increased hardware setup complexity and hardware cost, large measurement error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

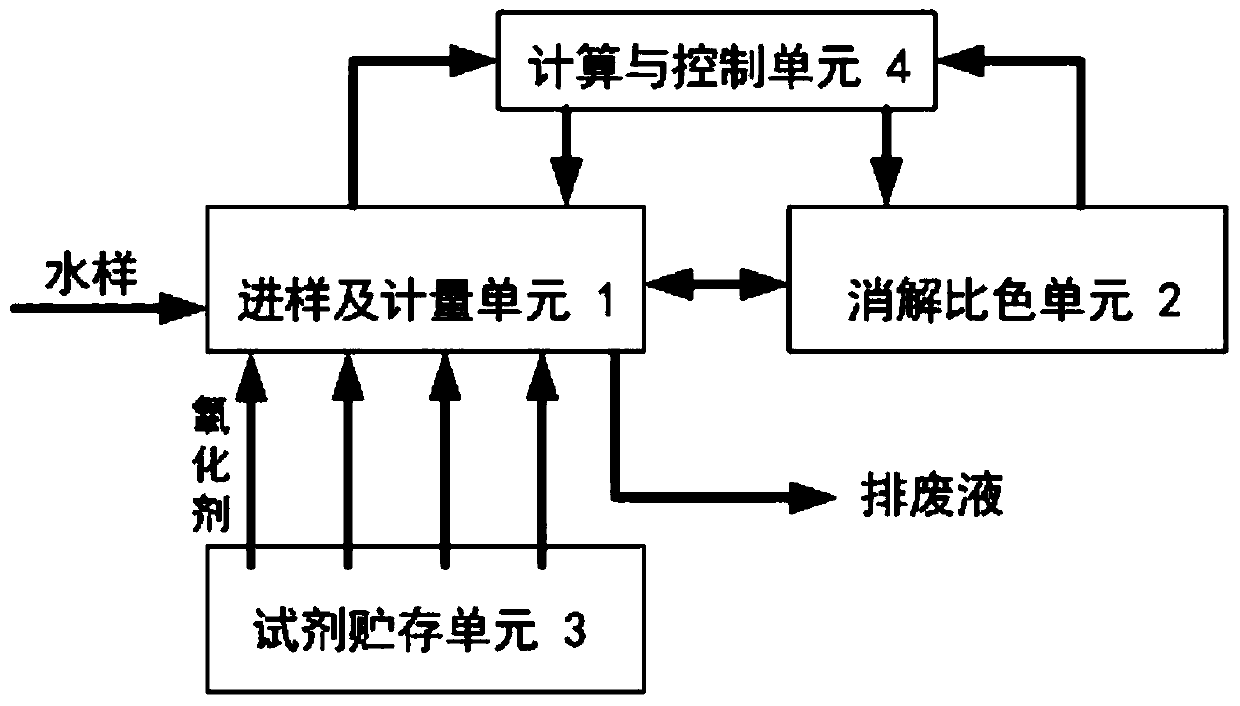

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A spectrophotometric water quality automatic testing process, including but not limited to the following steps:

[0047] S100. The sampling and metering unit 1 extracts a specified dose of water sample and injects it into the digestion and colorimetric unit 2, and bubbling evenly;

[0048] S200. The sampling and metering unit 1 extracts a specified dose of oxidant from the reagent storage unit 3 and injects it into the digestion colorimetric unit 2, and bubbles evenly;

[0049] S300. measure the light intensity that the digestion colorimetric unit 2 passes through the sample chamber 21 sample output before digestion, and record it as the reference light intensity I parameter;

[0050] S400. The digestion colorimetric unit 2 digests the sample in the sample chamber 21;

[0051] S500. After the digestion is completed, the digestion sample is left to stand for a period of time;

[0052] S600. After standing still, the sample injection and metering unit 1 re-bubbles the d...

Embodiment 2

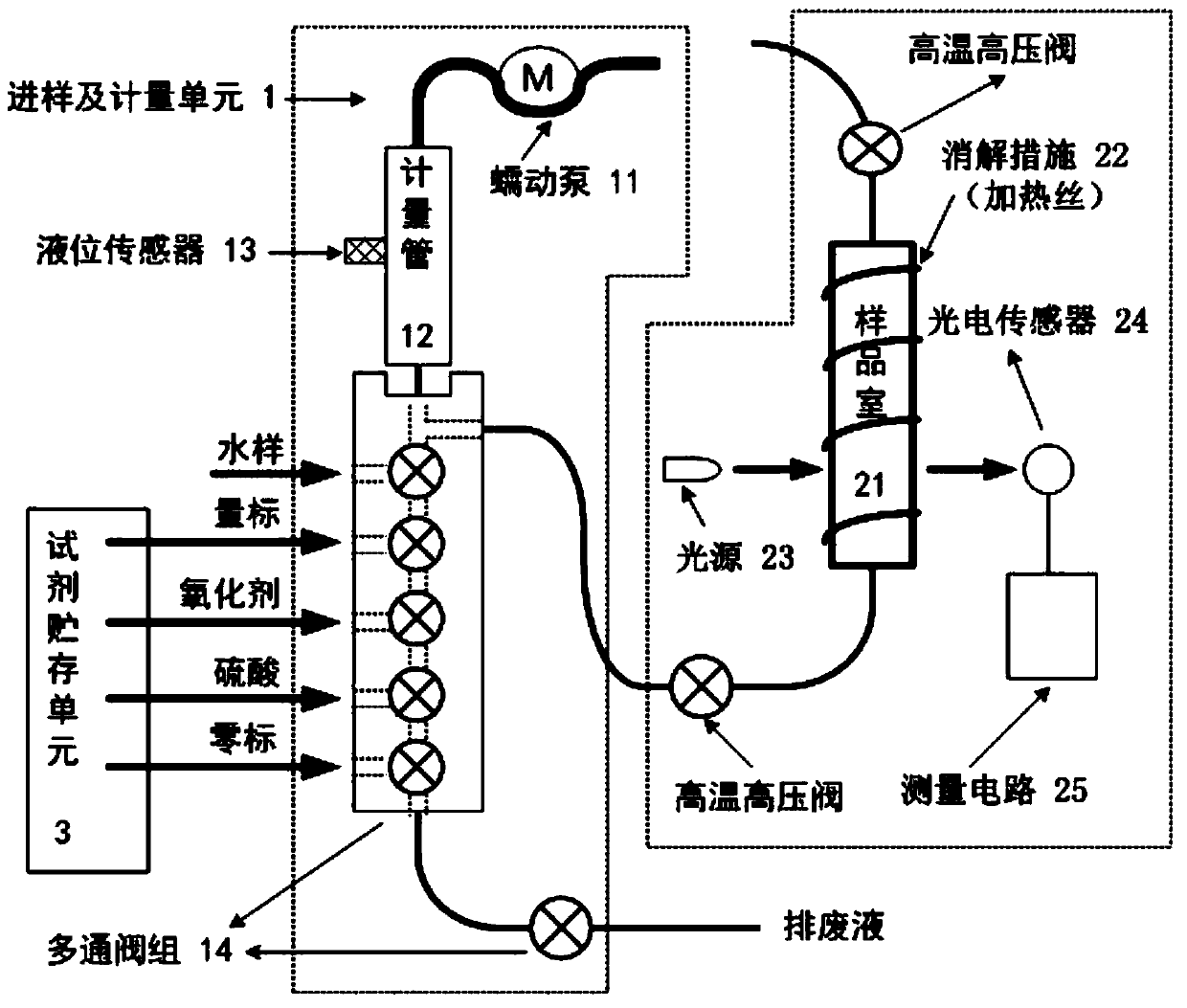

[0062] This embodiment is basically the same as Embodiment 1, the difference is that: the digestion measure 22 adopts a high temperature and high pressure method, such as figure 2 shown.

Embodiment 3

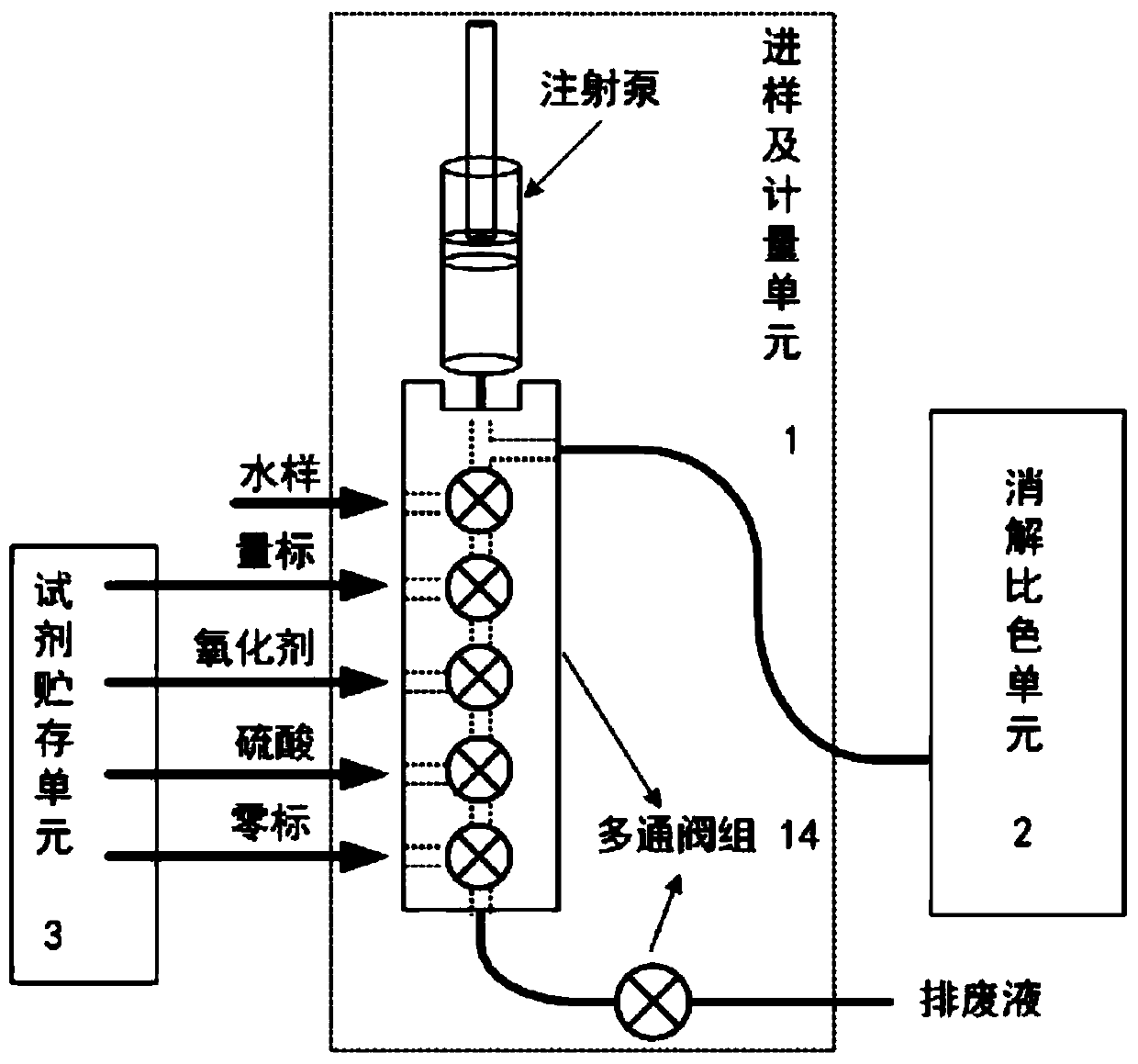

[0064] This embodiment is basically the same as Embodiment 1, except that the "peristaltic pump 11+metering tube 12+liquid level sensor 13" in the device is replaced by a syringe pump, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com