Accelerated on-line test system for service life of LED

An online testing and lifespan technology, which is applied in the direction of single semiconductor device testing, etc., can solve problems such as difficult LED temperature control, inconvenient simultaneous control, and deviation of test results, etc., to achieve accurate and stable temperature control, complete test parameters, and accurate prediction of life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0034] (1) Select 20-30 samples from the same batch, and store them at 100°C for 100 hours for pre-aging, and remove the samples that fail quickly.

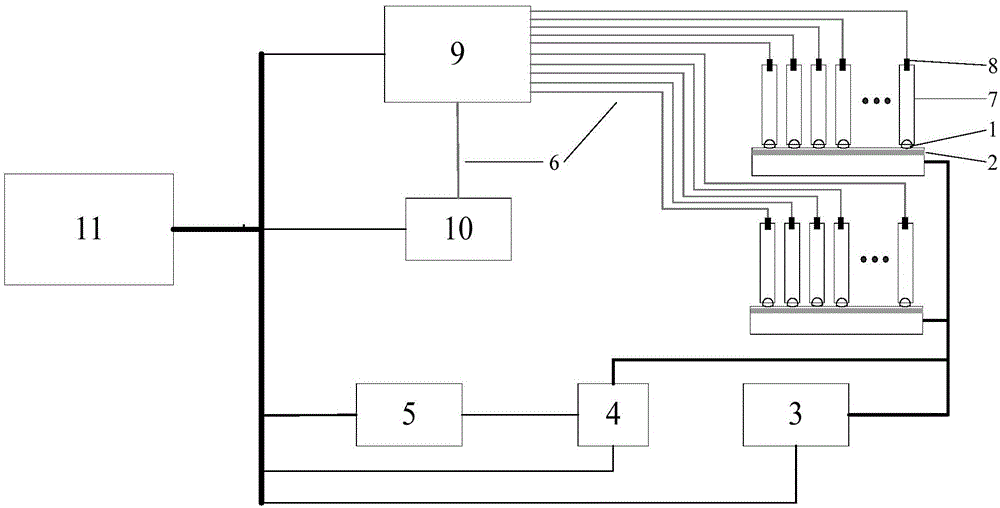

[0035] (2) Fix the sample on the sample holder, and press figure 1 Connect the test equipment. The pre-aging samples were tested and screened, and 16 samples with similar properties were selected as experimental samples.

[0036] (3) Select the experimental stress. Select 2 to 4 temperature points or current points as the acceleration stress according to the sample, set the temperature and current through the computer, control the temperature of the LED heat sink, and light the LED through the aging constant current source. For example, according to the TM-21 standard, the three temperature points of 55°C, 85°C, and 115°C are selected as the accelerated stress, and the rated current is used to supply power, and the number of samples in each group is 5, 5, and 6 respectively, and the test is carried out.

[0037] (4) Testing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com