Reliability evaluation method for top beam of hydraulic bracket

A hydraulic support, reliable technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

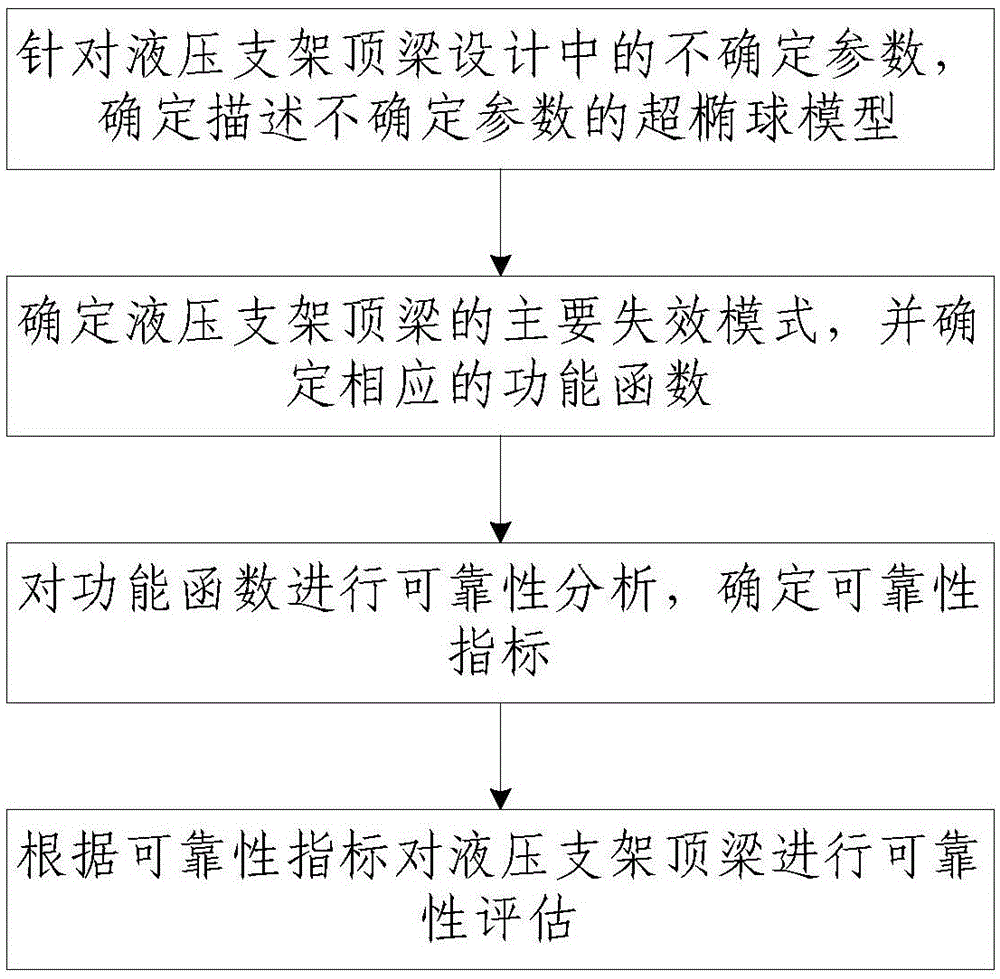

[0043] like figure 1 Shown, reliability evaluation method of the present invention, comprises the following steps:

[0044] Step 1. Aiming at the uncertain parameters in the design of the hydraulic support top beam, determine the hyperellipsoid model describing the uncertain parameters. The specific process is:

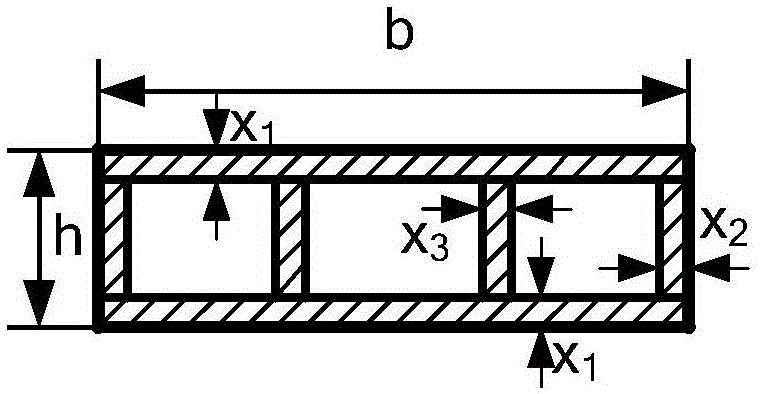

[0045] Step 101, for the uncertain parameter vector x=[x 1 ,x 2 ,...,x k ] T Using a hyperellipsoid model to describe, determine the center of the hyperellipsoid The semi-axis of the hyperellipsoid a=[a 1 ,a 2 ,...,a k ] T , the semi-axis of the hyperellipsoid and x 1 ,x 2 ,...,x k-1 Angle α in the positive direction of the corresponding coordinate axis 1 ,α 2 ,...,α k-1 ; Wherein, k is the number of uncertain parameters in the hydraulic support top beam structure;

[0046] Step 102, through linear transformation L(x), construct a local coordinate system with the center of the hyperellipsoid as the origin and the semi-axis of the hyperellipsoid as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com