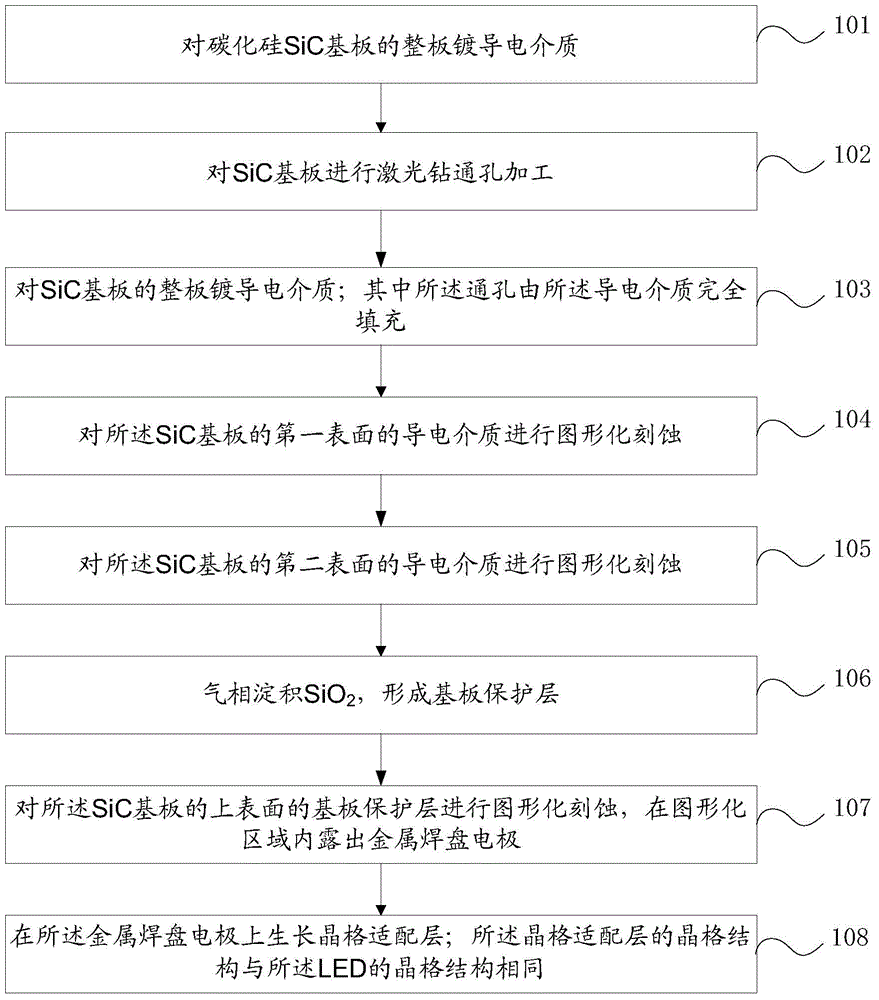

Method of manufacturing LED laminated circuit board based on inorganic substance

A manufacturing method and circuit board technology, which is applied to circuits, electrical components, semiconductor devices, etc., can solve problems such as inability to guarantee performance consistency, cumbersome bonding process, and hidden dangers of product stability and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

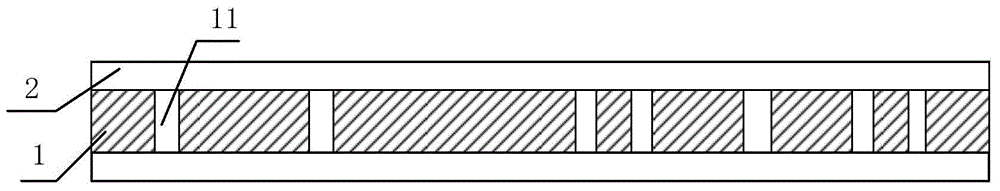

[0067] The preparation method of the above step 101-step 108 provides a method for preparing a single-layer LED substrate. If a multi-layer substrate is to be prepared, the following steps can be performed before the above step 106:

[0068] 1) Vapor deposition of SiC to form the filling layer of the patterned etching area and the surface insulating layer of the SiC substrate;

[0069] 2) performing patterned etching on the surface insulating layer of the SiC substrate, and etching until the conductive medium is exposed in the patterned area;

[0070] 3) Plating a conductive medium on the entire board of the SiC substrate;

[0071] 4) performing patterned etching on the conductive medium on the first surface of the SiC substrate;

[0072] 5) Perform patterned etching on the conductive medium on the second surface of the SiC substrate.

[0073] The above steps 1)-5) can be repeated multiple times according to the required number of substrate layers.

[0074] The method for m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com