Food drying processing device

A technology of a processing device and a drying device, which is applied in food processing, food drying, food preservation and other directions, can solve the problems of unguaranteed drying quality, high food oil content, incomplete food drying, etc., and is easy to popularize. Use, high evaporation strength, reasonable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

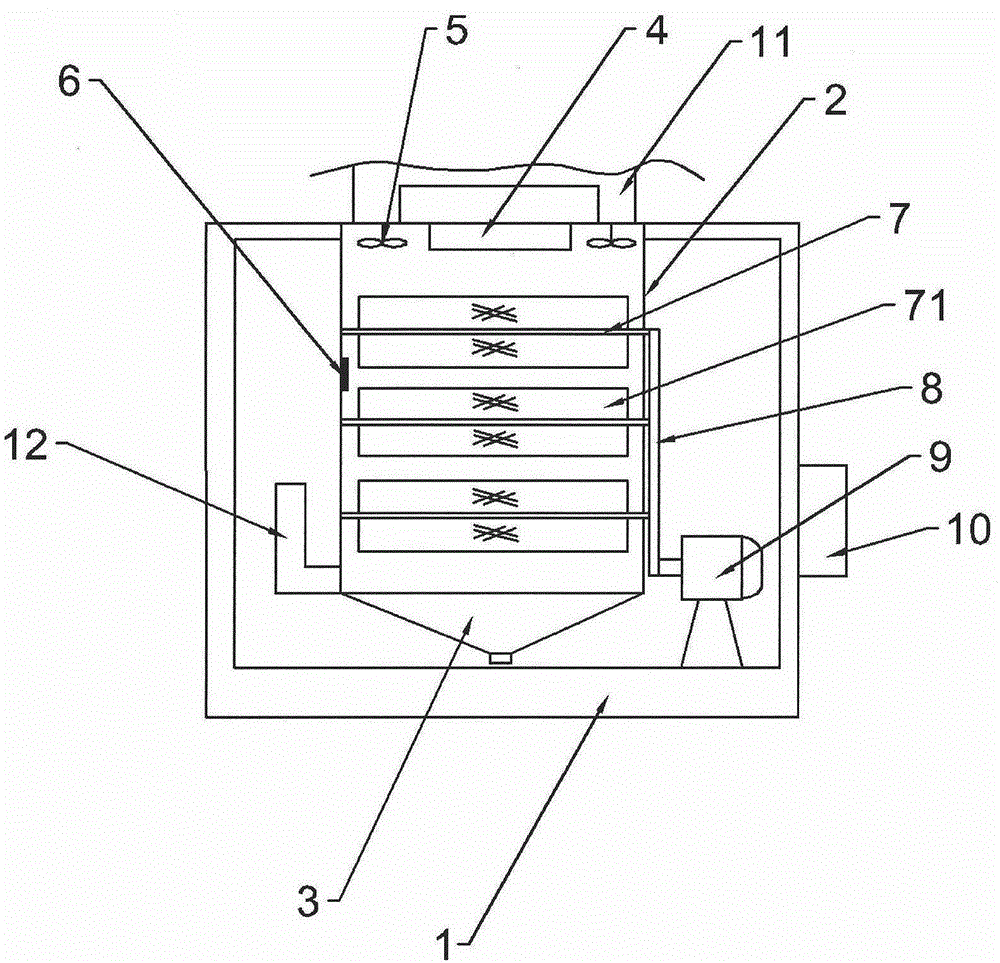

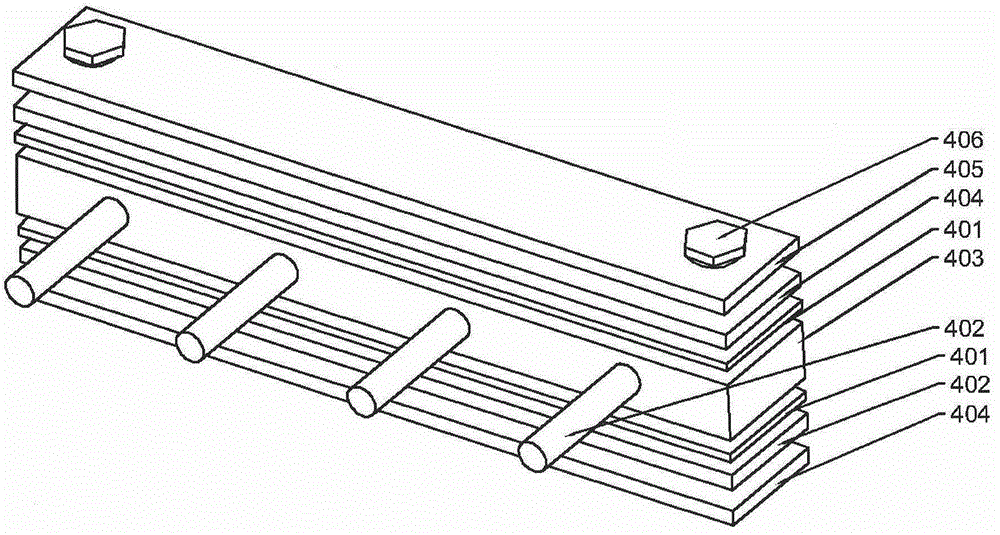

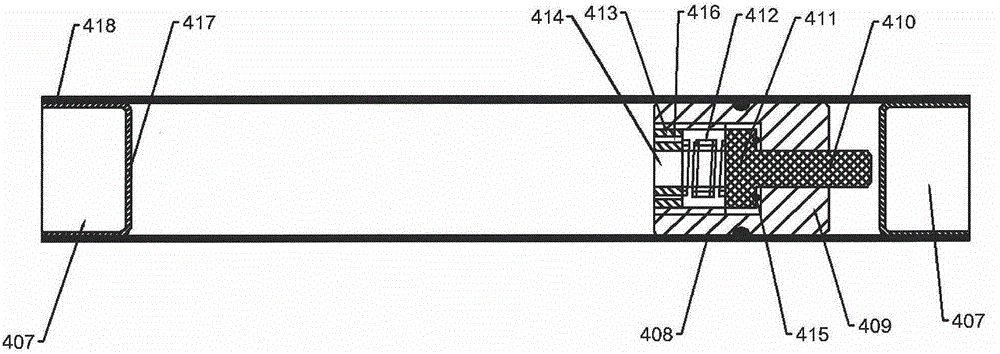

[0018] see Figure 1-3 , a food drying and processing device, comprising a support 1, a body 2 fixed on the support 1, a superconducting heating device 24, a drying device, a driving device and a control box 10, the superconducting heating device 4 is fixed on the top of the body 2, The superconducting heating device 4 is electrically connected to the control box 10, and the superconducting heating device 4 includes a PTC heating sheet 401, an energy-saving superconducting heat transfer pipe 402, a heat exchange plate 403, an insulating layer 404, a fixing plate 405 and fastening bolts 406, the upper and lower ends of the heat exchange plate 403 are respectively fixedly connected with the PTC heating plate 401, the side walls of the heat exchange plate 403 are evenly provided with sockets, and the energy-saving superconducting heat transfer pipes 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com