Spray-drying device

A drying device and drying chamber technology, applied in the directions of spray evaporation, evaporator accessories, liquid separation into droplets and granulation, etc., can solve the problem of inability to obtain high-quality raw materials, etc., and achieve fast drying speed, good uniformity, and increased surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following, numerous specific details are set forth in order to provide a thorough understanding of the concepts underlying the described embodiments. It will be apparent, however, to one skilled in the art that the described embodiments may be practiced without some or all of these specific details. In other instances, well known processing steps have not been described in detail.

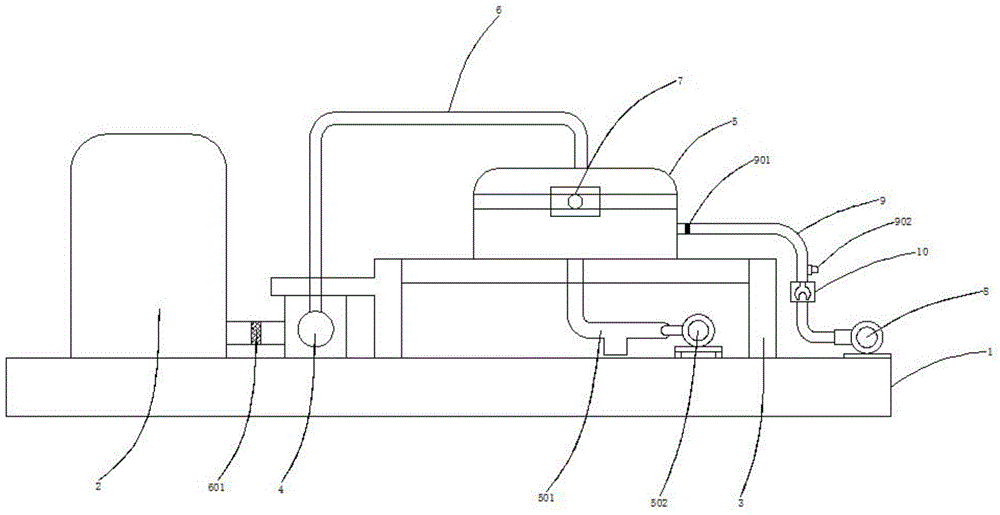

[0022] Such as figure 1 As shown, it includes a working table 1, a raw material tank 2, a frame 3, a centrifugal pump 4, a drying chamber 5, a feeding pipeline 6, an atomizer 7, a blower 8, a hot air pipeline 9, a heating plate 10, a discharge pipeline 501, and a draft Machine 502, steel wire mesh 601, canvas filter screen 901, temperature limiter 902, frame 3 is located at the top of worktable 1, centrifugal pump 4 is located at the outlet of raw material tank 2, which is connected with frame 3 by threads, and drying chamber 5 is located at At the center of the top of the frame 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com