Device and technological method for repairing organic contaminated soil and underground water

A technology of organic pollution and process method, applied in the field of remediation of organic polluted soil, can solve the problems of high treatment cost, complicated process, secondary pollution, etc., and achieve the effect of simple device design, avoiding secondary pollution, and reducing treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

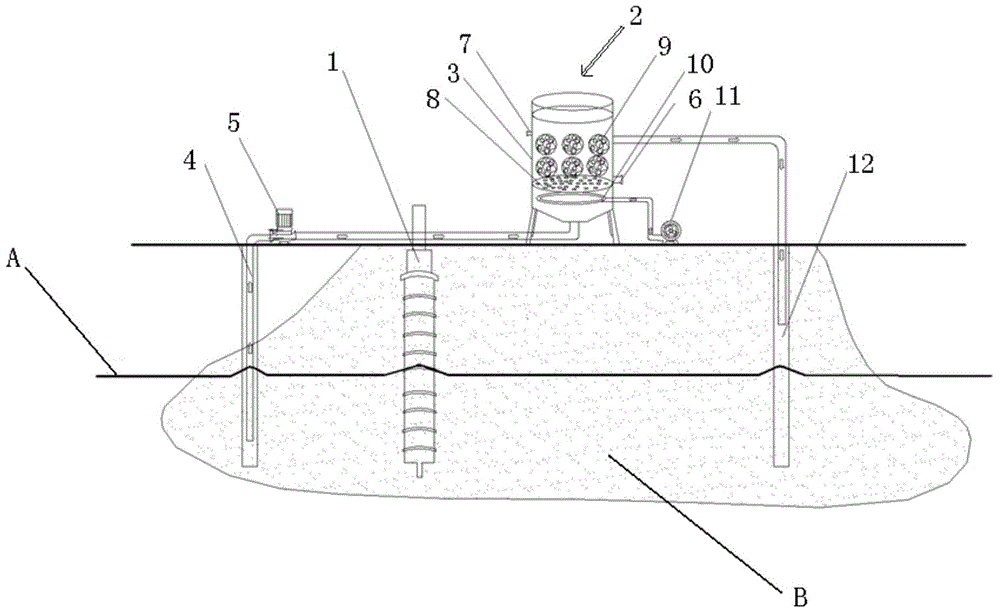

Embodiment 1

[0025] Embodiment 1: This embodiment is to remediate the soil polluted by o-(p) dinitrochlorobenzene with a concentration of 2000ppm, the groundwater depth is 2m, and the contaminated area covers an area of 1000m 2 , Drill 50 holes in the site, install an ultrasonic transmitter, the depth of the transmitter reaches 5m, turn on the ultrasonic frequency of 30kHz, and take out the ultrasonic transmitter after 0.5 months of operation. Install pumping pipelines in 25 evenly distributed boreholes, connect to surface self-priming pumps, and carry out microbial enhanced reaction, and install drainage pipelines in the other 25 boreholes. The domesticated Acinetobacter high-efficiency aerobic degrading bacteria attached to the filler is installed in the microbe-enhanced reactor. Add nutrient solution to ensure the C:N:P=(100~120):(4~8):(0.5~2) of the total nutrients in the container. At the same time, adjust the internal pH to 6~7.5 and control the temperature at 10 At ~30°C, the aer...

Embodiment 2

[0026]Embodiment 2: This embodiment is to remediate the soil polluted by HCHs (HCHs) with a concentration of 2500ppm, the groundwater depth is 4m, and the contaminated area covers an area of 500m 2 . Drill 30 holes in the site, install an ultrasonic transmitter, turn on the ultrasonic frequency of 50kHz, and take out the ultrasonic transmitter after 2 months of operation. Install pumping pipelines in 15 evenly distributed boreholes, connect to surface self-priming pumps, and carry out microbial enhanced reaction, and install drainage pipelines in the other 15 boreholes. The domesticated Pseudomonassp efficient aerobic degrading bacteria attached to the filler is installed in the microbe enhanced reactor. Add nutrient solution to ensure the C:N:P=(100~120):(4~8):(0.5~2) of the total nutrients in the container. At the same time, adjust the internal pH to 6~7.5 and control the temperature at 20 At ~35°C, the aerator is turned on and ventilated into the device at 200L / min. Gr...

Embodiment 3

[0027] Embodiment 3: This embodiment is to remediate the soil polluted by DDTs (DDTs) with a concentration of 1000ppm, the groundwater depth is 1m, and the contaminated area covers an area of 200m 2 . Drill 10 holes in the site and install ultrasonic transmitters with a depth of 3m. Turn on the ultrasonic frequency of 35kHz, and take out the ultrasonic transmitter after 1.5 months of operation. Install pumping pipelines in 25 evenly distributed boreholes, connect to surface self-priming pumps, and carry out microbial enhanced reaction, and install drainage pipelines in the other 25 boreholes. The domesticated Enterobactersp high-efficiency aerobic degrading bacteria attached to the filler is installed in the microbe-enhanced reactor. Add nutrient solution to ensure the C:N:P=(100~120):(4~8):(0.5~2) of the total nutrients in the container. At the same time, adjust the internal pH to 6~7.5 and control the temperature at 20 At ~35°C, the aerator is turned on and the air is v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com