A classification treatment method for saline-alkali land

A technology for grading treatment and saline-alkali land, applied in chemical instruments and methods, restoration of polluted soil, and other chemical processes. The degree of salinity and the effect of enhancing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

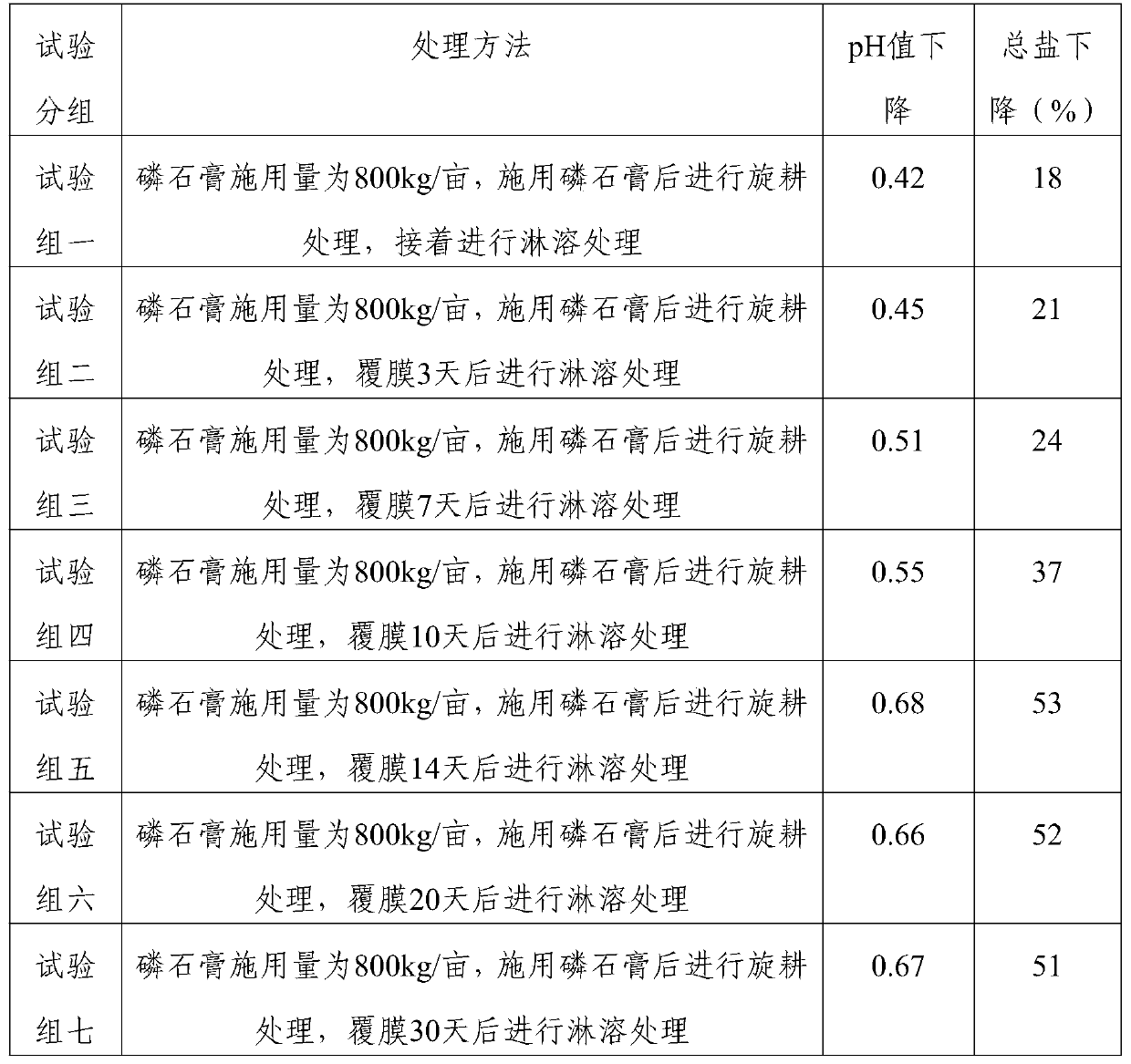

Embodiment 1

[0056] A graded treatment method for saline-alkali land, comprising the following steps:

[0057] (1) Rectorite pretreatment: use a ball mill to grind rectorite into a fine powder with a fineness of ≤0.05mm, then send it into an ultrasonic device, process it for 20min at an ultrasonic power of 600w, and then send it into a calcination tower with a temperature of 300°C. Calcined at high temperature for 2 hours, cooled and sent to the reaction tank, and then acidified by adding acid for 30 minutes to obtain rectorite powder, the weight ratio of rectorite to acid is 60:10, and the acid is 30% concentration nitric acid;

[0058] (2) Fermentation: send the oil sour, fungal chaff and EM bacterial agent into the fermentation tank and mix evenly, adjust the water content of the mixture to 50%, and control the fermentation temperature to 40°C within 4 days of fermentation, and control the fermentation temperature for the next 8 days At 55°C, the fermentation material was obtained, and...

Embodiment 2

[0064] A graded treatment method for saline-alkali land, comprising the following steps:

[0065](1) Rectorite pretreatment: use a ball mill to grind rectorite into a fine powder with a fineness of ≤0.05mm, then send it into an ultrasonic device, treat it for 40min at an ultrasonic power of 1000w, and then send it into a calcination tower with a temperature of 600°C. Calcined at high temperature for 3 hours, cooled and sent to the reaction tank, and then acidified by adding acid for 100 minutes to obtain rectorite powder, the weight ratio of rectorite to acid is 80:20, and the acid is 30% concentration sulfuric acid;

[0066] (2) Fermentation: send the oil sour, fungal chaff and EM bacterial agent into the fermentation tank and mix them evenly, adjust the water content of the mixture to 60%, and control the fermentation temperature to 50°C within 6 days of fermentation, and control the fermentation temperature for the next 9 days at 70°C to obtain the fermentation material, t...

Embodiment 3

[0072] A graded treatment method for saline-alkali land, comprising the following steps:

[0073] (1) Rectorite pretreatment: use a ball mill to grind rectorite into a fine powder with a fineness of ≤0.05mm, then send it into an ultrasonic device, treat it at an ultrasonic power of 800w for 30min, and then send it into a calcination tower with a temperature of 600°C. Calcined at high temperature for 3 hours, cooled and sent to the reaction tank, and then acidified by adding acid for 80 minutes to obtain rectorite powder, the weight ratio of rectorite to acid is 70:15, and the acid is 35% concentration Nitric acid or 25% sulfuric acid;

[0074] (2) Fermentation: send the oil sour, fungus chaff and EM bacterial agent into the fermentation tank and mix evenly, adjust the water content of the mixture to 55%, within 5 days of fermentation, control the fermentation temperature to 45°C, and then control the fermentation temperature for 10 days The fermentation material was obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com