Double-piston metal laser selective melting molding equipment

A technology of laser selective melting and forming equipment, applied in the field of additive manufacturing, can solve the problems of internal structure of forming components, uneven distribution of stress and strain, waste of powder, insufficient consideration of preheating, etc., achieve good heat conduction characteristics, avoid material waste, The effect of high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing, the present invention will be further described:

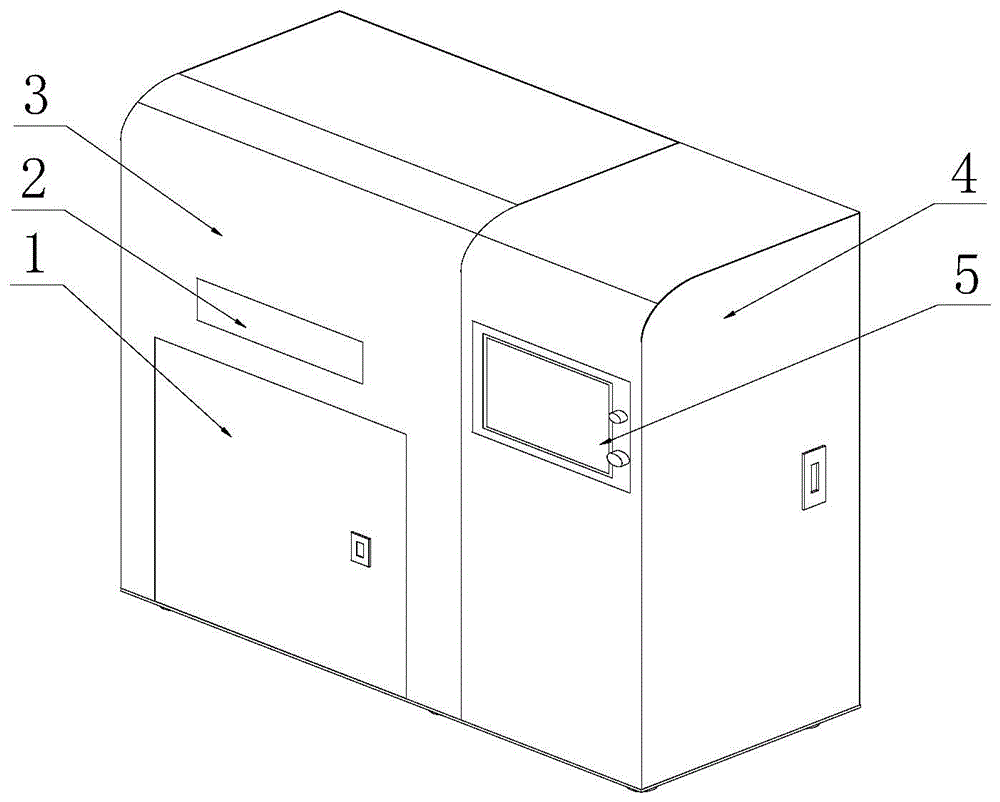

[0040] like figure 1 As shown, the present invention is a double-piston metal laser selective melting and forming equipment. The main body 1 and the auxiliary body 4 are fixed inside the casing 3 , and the main body 1 is on the left side of the auxiliary body 4 . The casing 3 of the main body 1 is provided with an observation window 2, and the observation window 2 is made of light green glass material, which can prevent 1030-1080nm laser radiation from causing harm to the human body. The casing 3 of the auxiliary body 4 is provided with an operation panel 5, the operation panel is a touch screen, and a keyboard is arranged under it for operating the forming equipment.

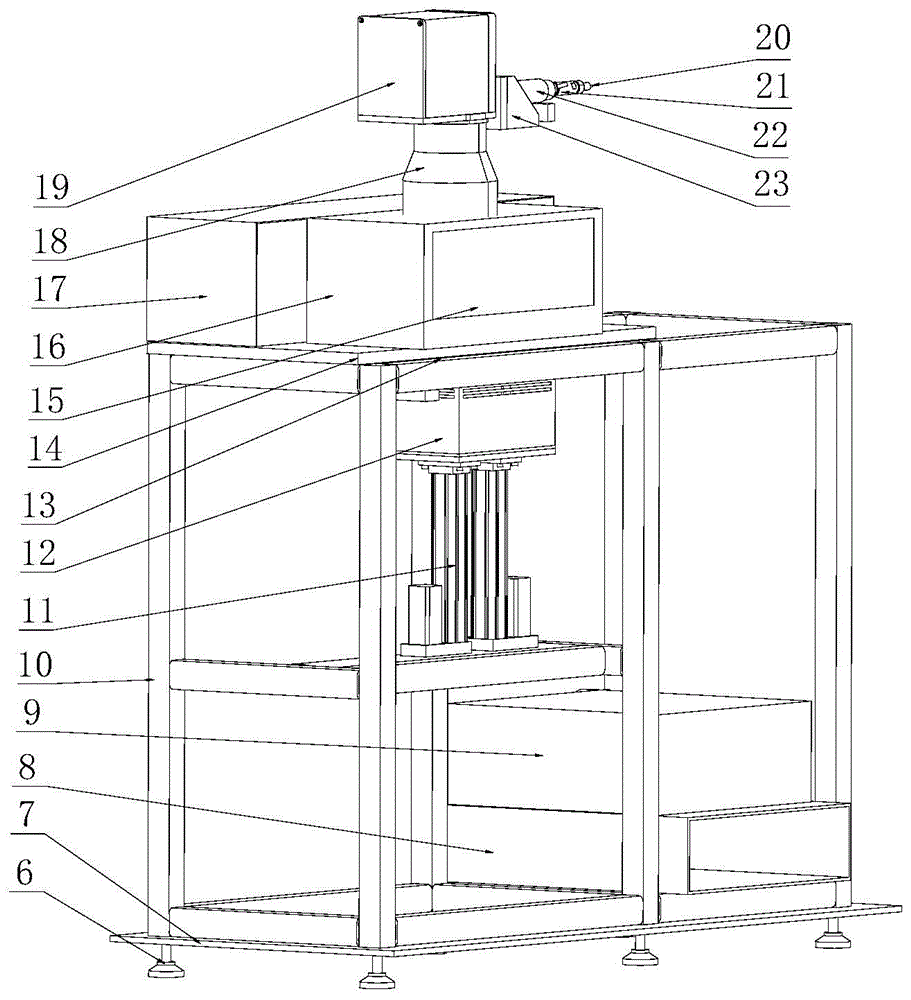

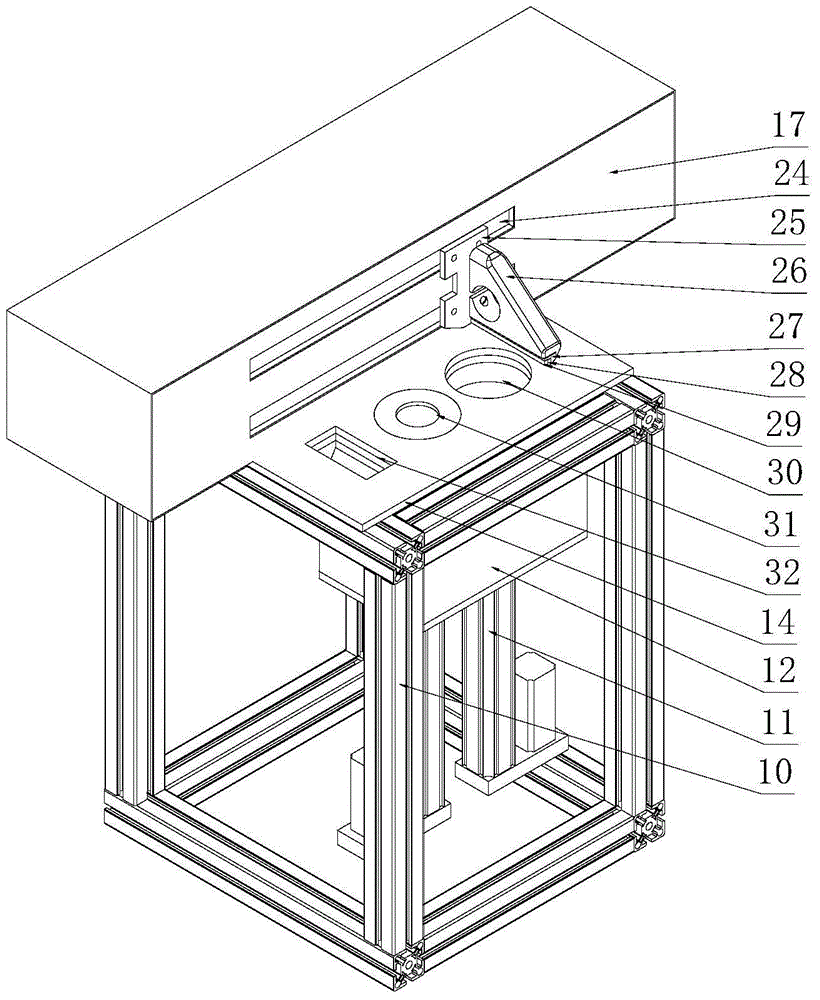

[0041] like figure 2 As shown, the frame 10 is formed by splicing aluminum alloy profiles or welding rectangular steel. A base plate 7 is provided at the bottom of the frame 10, and feet are installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com