A special tool for high-efficiency hole-making of fiber-reinforced composite materials

A composite material and fiber-reinforced technology, which is applied in metal processing and other directions, can solve problems such as delamination, burrs, tears, and poor hole wall quality, and achieve low-damage hole making, quality improvement, and reduction of drilling axial force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

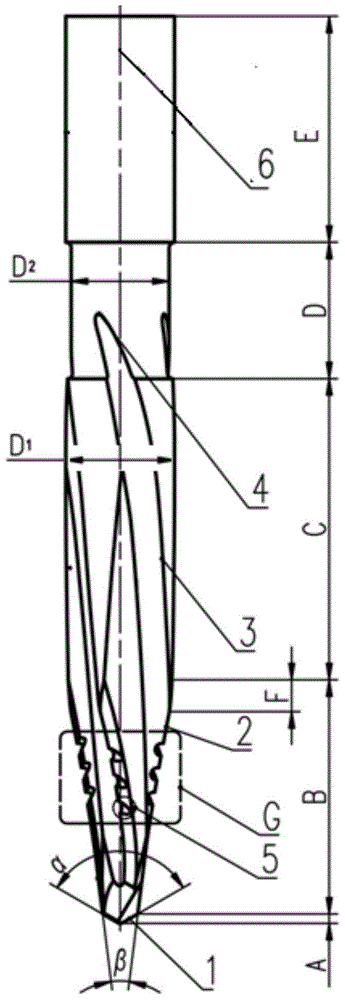

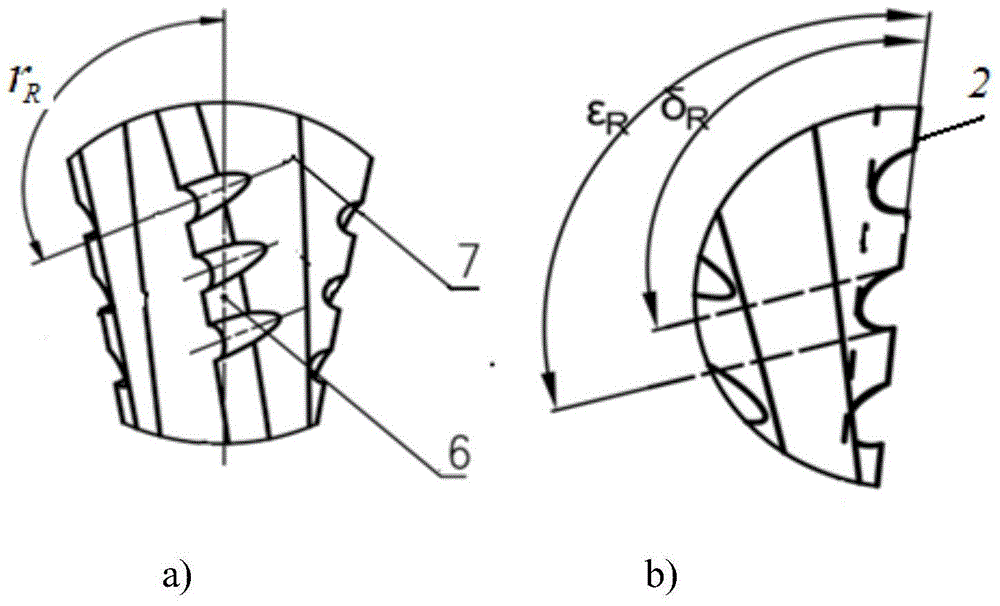

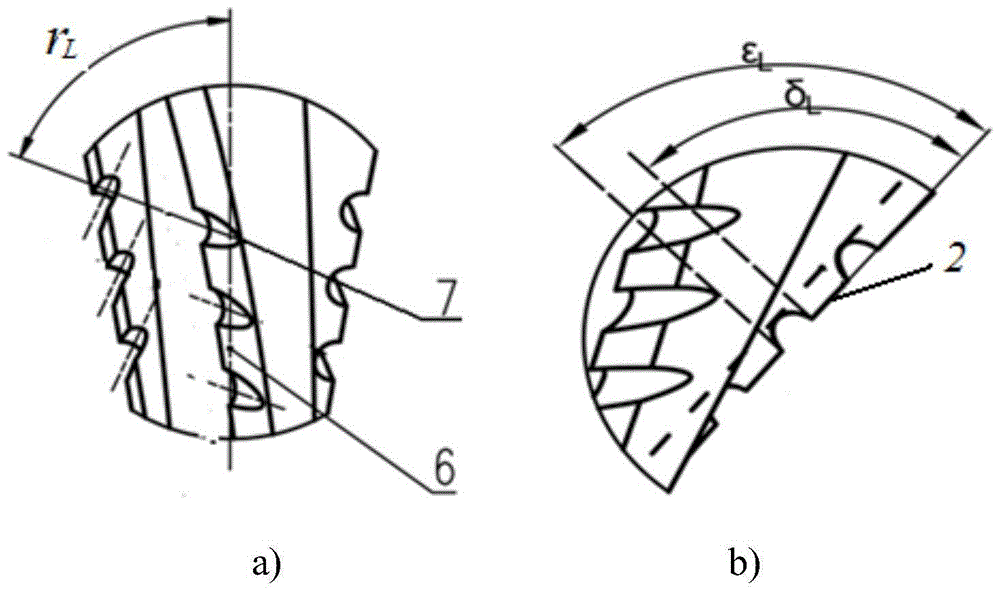

[0009] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions. A fiber-reinforced composite high-efficiency hole-making cutter, its specific embodiment cutter is as figure 1 As shown, the tool is divided into the first main cutting area A formed by the envelope of the first main cutting edge 1, the second main cutting area B formed by the envelope of the second main cutting edge 2, and the envelope is the end hole The size of the left-handed helix is the six areas of secondary cutting area C, variable diameter area D, clamping area E and micro-tooth cutting area G. Among them, the first main cutting area A has two first main cutting edges 1, and the apex angle α formed by them is an obtuse angle, so that the first main cutting edge 1 has high rigidity and can better center after drilling. function, to ensure the smooth progress of the drilling subsequent drilling process, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com