Composite material for yoga balls and preparation method of composite material

A technology of composite materials and mixtures, applied in the field of composite materials for yoga balls and its preparation, can solve the problems of dirty yoga balls, not easy to clean, and insufficient elasticity, and achieve low cost, good market prospects, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

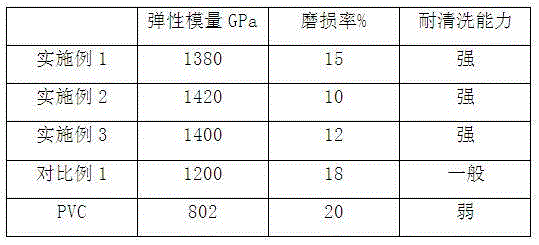

Examples

Embodiment 1

[0022] A composite material for a yoga ball, made of the following components in parts by weight: 40 parts of PVC, 1 part of anti-aging agent, 12 parts of carbon fiber, 5 parts of rubber powder 5 parts of sodium edetate, 1 part of glycerin, 0.1 part of 80 mesh talcum powder, 3 parts of olive oil, 1 part of 120 mesh plastic powder, and 0.2 part of acetic acid.

[0023] The preparation method of the above-mentioned yoga ball composite material comprises the following steps:

[0024] Step 1, mix PVC, rubber powder, talcum powder, and plastic powder and put them into a grinder to grind through a 400-mesh sieve to obtain the first mixture;

[0025] Step 2, adding carbon fiber, sodium edetate, glycerin and acetic acid to the first mixture, stirring at 340rpm, transferring to a reaction kettle, and heating in vacuum to 200-350°C to obtain the second mixture;

[0026] In step 3, olive oil is added to the second mixture by spraying, and after stirring, transfer to a granulator to gran...

Embodiment 2

[0028] A composite material for a yoga ball, made of the following components in parts by weight: 48-52 parts of PVC, 2-4 parts of anti-aging agent, 14-4 parts of carbon fiber 16 parts, 8-12 parts of rubber powder, 6-8 parts of sodium edetate, 2-4 parts of glycerin, 0.1-0.2 parts of 100 mesh talcum powder, 4-6 parts of olive oil, 4-6 parts of 180 mesh plastic powder Parts, 0.3-0.4 parts of acetic acid.

[0029] The preparation method of the above-mentioned yoga ball composite material comprises the following steps:

[0030] Step 1, mix PVC, rubber powder, talcum powder, and plastic powder and put them into a grinder to grind through a 400-mesh sieve to obtain the first mixture;

[0031] Step 2, adding carbon fiber, sodium edetate, glycerin and acetic acid to the first mixture, stirring at 400rpm, transferring to a reaction kettle, and heating to 200-350°C under vacuum to obtain the second mixture;

[0032] In step 3, olive oil is added to the second mixture by spraying, and ...

Embodiment 3

[0034] A composite material for a yoga ball, made of the following components by weight: 40-55 parts of PVC, 1-5 parts of anti-aging agent, 12-5 parts of carbon fiber 18 parts, 5-12 parts of rubber powder, 5-9 parts of sodium edetate, 1-5 parts of glycerin, 0.1-0.5 parts of 100 mesh talcum powder, 3-6 parts of olive oil, 1-6 parts of 180 mesh plastic powder part, 0.2-0.5 part of acetic acid.

[0035] The preparation method of the above-mentioned yoga ball composite material comprises the following steps:

[0036] Step 1, mix PVC, rubber powder, talcum powder, and plastic powder and put them into a grinder to grind through a 400-mesh sieve to obtain the first mixture;

[0037] Step 2, adding carbon fiber, sodium edetate, glycerin and acetic acid to the first mixture, stirring at 420rpm, transferring to a reaction kettle, and heating in vacuum to 200-350°C to obtain the second mixture;

[0038] In step 3, olive oil is added to the second mixture by spraying, and after stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com