A kind of gas phase hydrogenation desulfurization process method of diesel oil

A diesel oil and hydrogenation treatment technology, applied in refining to remove heteroatoms, etc., can solve the problems of high equipment investment cost, high reaction pressure, etc., and achieve the effect of high reaction pressure and high vaporization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

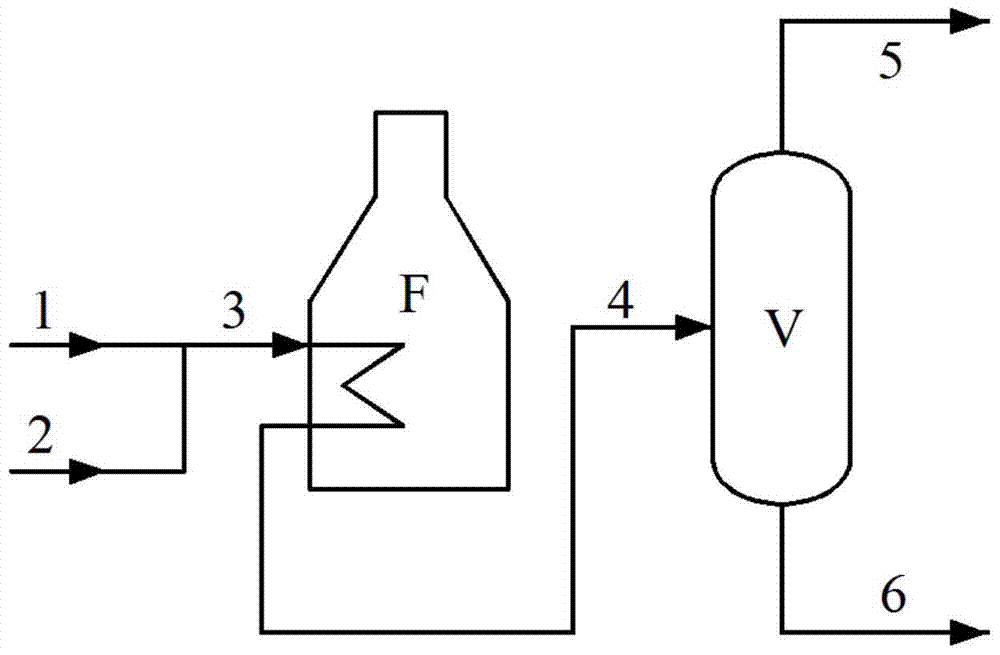

Method used

Image

Examples

Embodiment 1

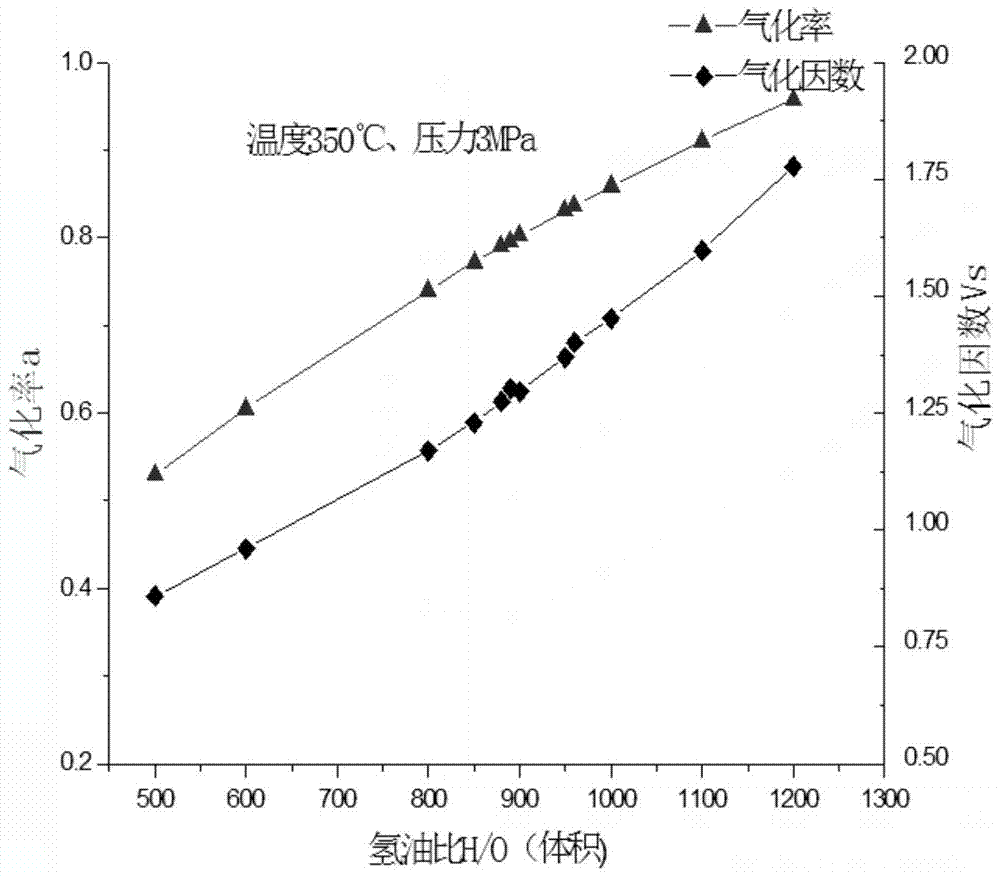

[0035] In this example, the reaction temperature is 350℃ and the space velocity is 1.5h -1 Under the conditions, the hydrodesulfurization effect of reaction pressure 6MPa and reaction pressure 3MPa. The hydrogen-to-oil ratio selected for the high-pressure 6MPa process is 600:1. According to the established model, the vaporization rate of the selected raw materials and the vaporization factors of three typical sulfides under this condition are calculated. Calculate the results of the vaporization rate of the raw materials and the vaporization factors of three typical sulfides with the ratio of hydrogen to oil at a low pressure of 3MPa. According to the analysis of the thermodynamic properties of the raw materials at 350℃, 4,6-dimethyldibenzothiophene is used as the global sulfide Substitutes. Such as figure 2 , Make the reaction pressure 6MPa, hydrogen-oil ratio 600:1, the product of reaction pressure and 4,6-dimethyldibenzothiophene vaporization factor and reaction pressure 3M...

Embodiment 2

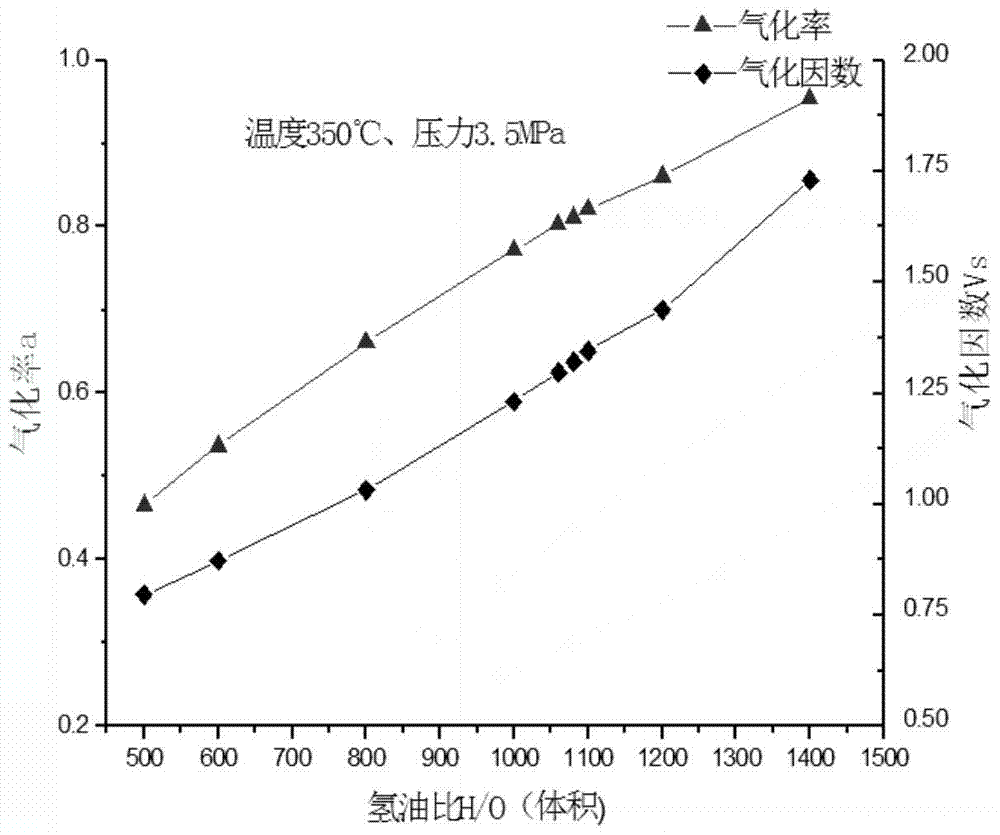

[0037] In this example, the reaction temperature is 350℃ and the space velocity is 1.5h -1 Under the conditions, the hydrodesulfurization effect of reaction pressure of 7MPa and reaction pressure of 3.5MPa. The hydrogen-to-oil ratio selected for the high-pressure 7MPa process is 600:1. According to the established model, the vaporization rate of the selected raw materials and the vaporization factors of three typical sulfides under this condition are calculated. Calculate the results of the vaporization rate of raw materials and the vaporization factors of three typical sulfides with the hydrogen-oil ratio under low pressure 3.5MPa. According to the analysis of the thermodynamic properties of raw materials at 350℃, 4,6-dimethyldibenzothiophene was used as a global sulfide substitute. Such as image 3 Under the conditions of reaction pressure of 7MPa and hydrogen-oil ratio of 600:1, the product of reaction pressure and 4,6-dimethyldibenzothiophene vaporization factor is equal to...

Embodiment 3

[0039] In this example, the reaction temperature is 350℃ and the space velocity is 1.5h -1 Under the conditions, the reaction pressure is 8MPa and the reaction pressure is 4MPa. The hydrogen-to-oil ratio selected for the high-pressure 8MPa process is 600:1. According to the established model, the vaporization rate of the selected raw materials and the vaporization factors of three typical sulfides under this condition are calculated. Calculate the results of the vaporization rate of the raw material and the vaporization factor of three typical sulfides with the hydrogen-oil ratio at a low pressure of 4MPa. According to the analysis of the thermodynamic properties of raw materials at 350℃, 4,6-dimethyldibenzothiophene was used as a global sulfide substitute. Such as Figure 4 , Make the reaction pressure 8MPa, hydrogen-oil ratio 600:1, the product of reaction pressure and 4,6-dimethyldibenzothiophene vaporization factor and reaction pressure 4MPa, hydrogen-oil ratio n conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com