Brewage technique of soft red fresh wine

A wine, soft technology, applied in the field of soft red fresh wine brewing technology, can solve the problems of small share, low tannin, poor quality, etc., and achieve the effect of accelerating production and development, reducing waste of resources, and protecting profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

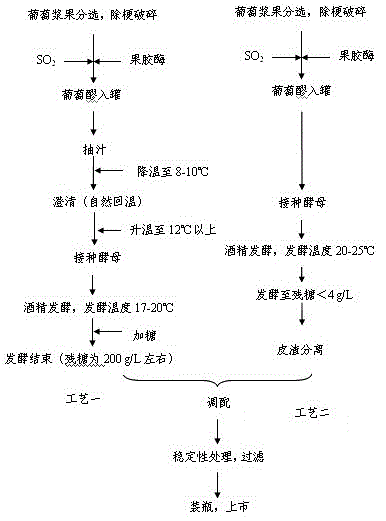

Image

Examples

Embodiment 1

[0020] A brewing process of soft red fresh wine, including the following steps: (1) raw material harvesting and sorting: no diseased fruit, moldy fruit, green fruit, and secondary fruit are required; (2) destemming and crushing: destemming and crushing, and at the same time Add 50mg / LSO2 and 30g / t pectinase, and then put it into the tank; (3) Without soaking: After the raw materials are put into the tank, immediately extract 15% of the grape juice; (4) Low-temperature clarification: Cool the extracted part of the grape juice to 8°C, add 30g / t pectinase for natural clarification; (5) inoculate yeast, alcoholic fermentation: return the grape juice to 12°C, separate the upper layer of grape juice, discard the lower layer of pulp, seeds, and high sediment content Add 250g / t active dry yeast D254 to the lower layer of grape juice, control the fermentation temperature at 20°C, add sugar after fermentation starts; do not extract juice from the mixed part of the skin juice, add 200g / t ...

Embodiment 2

[0022] A brewing process of soft red fresh wine, including the following steps: (1) raw material harvesting and sorting: no diseased fruit, moldy fruit, green fruit, and secondary fruit are required; (2) destemming and crushing: destemming and crushing, and at the same time Add 60mg / LSO2 and 20g / t pectinase, and then put it into the tank; (3) Without soaking: After the raw materials are put into the tank, immediately extract 16% grape juice; (4) Low-temperature clarification: cool down part of the extracted grape juice to 10°C, add 20g / t pectinase for natural clarification; (5) inoculate yeast, alcoholic fermentation: return the grape juice to 12°C, separate the upper layer of grape juice, discard the lower layer of pulp, seeds, and high sediment content Add 250g / t active dry yeast D254 to the lower grape juice, control the fermentation temperature at 17°C, add sugar after the fermentation starts; do not extract juice from the mixed part of the skin juice, add 200-250g / t active...

Embodiment 3

[0024]A brewing process of soft red fresh wine, including the following steps: (1) raw material harvesting and sorting: no diseased fruit, moldy fruit, green fruit, and secondary fruit are required; (2) destemming and crushing: destemming and crushing, and at the same time Add 55mg / LSO2 and 23g / t pectinase, and then put it into the tank; (3) Without soaking: After the raw materials are put into the tank, immediately extract 20% of the grape juice; (4) Low-temperature clarification: Cool the extracted part of the grape juice to 9°C, add 25g / t pectinase for natural clarification; (5) inoculate yeast, alcoholic fermentation: return the grape juice to 12°C, separate the upper layer of grape juice, discard the lower layer of pulp, seeds, and high sediment content Add 220g / t active dry yeast D254 to the lower grape juice, control the fermentation temperature at 17-20°C, add sugar after fermentation starts; do not extract juice from the mixed part of the skin juice, add 230g / t active ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com