High pressure air injection eddy making type eddy kinetic energy pulping equipment

A high-pressure air jet and vortex technology, which is applied in papermaking, textile and papermaking, and raw material separation, can solve the problems of high energy consumption and low efficiency, and achieve the effects of accelerating pulping efficiency, reducing kinetic energy loss, and improving pulping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

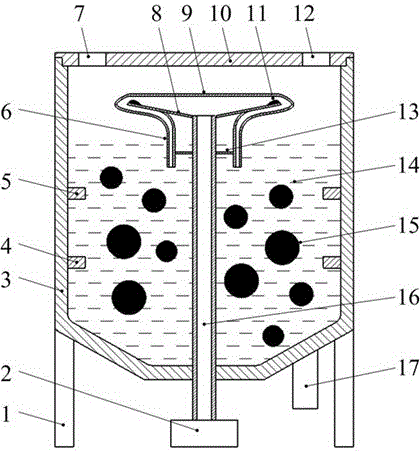

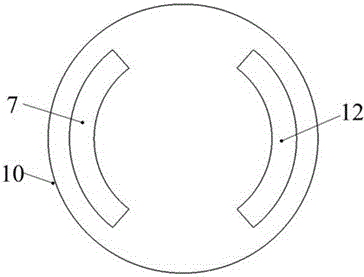

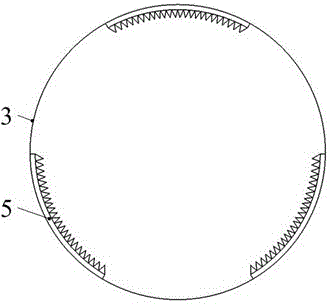

[0023] Such as figure 1 , figure 2 As shown, a high-pressure air-jet swirling-type vortex kinetic energy pulping equipment of the present invention mainly includes a slurry-slurry generating device, a high-pressure air supply device and a high-pressure air-jet swirling device. The high-pressure air supply device is mainly composed of an air compressor 2 and an air delivery pipe 16. The air compressor 2 is installed below the pulper barrel 3. The air delivery pipe 16 is drawn out from the air compressor 2 and goes deep into the pulper barrel 3. The air delivery pipe 16 Four supporting rods 13 uniformly distributed in the circumferential direction are installed on the upper end. Slurry The slurry generating device is mainly composed of a pulper cylinder 3 and a cylinder cover 10. The cylinder cover 10 is a disc-shaped structure, and the cylinder cover 10 is symmetrically opened with an arc-shaped feed and exhaust port A7 and a feed and exhaust port. Port B12; the pulper barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com