Composite heat-insulation plate cast-in-place concrete sandwiched wall structure

A concrete structure, composite thermal insulation technology, applied in thermal insulation, walls, building components, etc., can solve the problems of energy waste, reduce thermal insulation performance, heat loss of wall thermal insulation system, etc., to avoid thermal bridges, structural safety and durability, The effect of avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

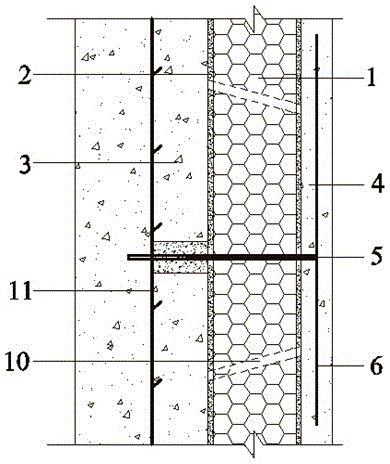

[0049] Such as Figure 1-Figure 3 As shown, a composite insulation board cast-in-situ concrete sandwich wall structure is composed of insulation board 1, fireproof layer 2, inner concrete structure layer 3, outer concrete protection layer 4 and tie positioning parts 5. The inner concrete structure layer 3 is used as the load-bearing structure of the building. The insulation board 1, the fireproof layer 2 and the outer concrete protection layer 4 together constitute the non-load-bearing insulation structure of the building. Reliable connection.

[0050] In order to increase the tie between the insulation board 1, the outer concrete protection layer 4 and the inner concrete structure layer 3, the tie positioning part 5 is installed after the insulation board 1 is arranged in the construction process, and they are tied together by the tie positioner 5 , tie locator 5 is made up of tie rod 12, locator piece 13 and concrete block 14, adopts reinforced composite concrete block, has...

Embodiment 2

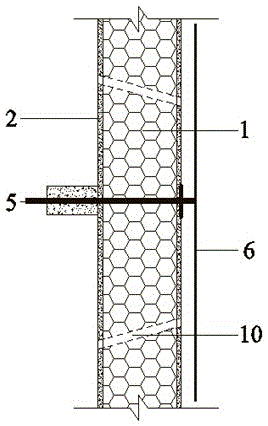

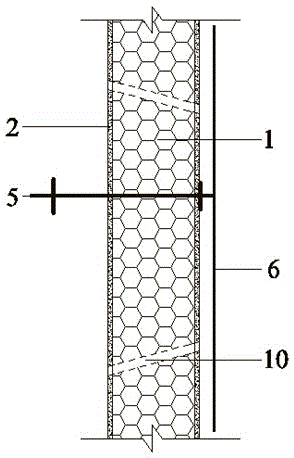

[0053] As shown in Figure 4-7, a composite insulation board cast-in-place concrete sandwich wall structure is composed of insulation board 1, fireproof layer 2, inner concrete structure layer 3, outer concrete protection layer 4 and tie positioning parts 5, The inner concrete structure layer 3 is used as the load-bearing structure of the building. The insulation board 1, the fireproof layer 2 and the outer concrete protection layer 4 together constitute the non-load-bearing insulation structure of the building. Reliable connection.

[0054] In order to increase the tie between the insulation board 1, the outer concrete protection layer 4 and the inner concrete structure layer 3, they are tied together through the tie locating piece 5, and the diameter of the steel bar used for the tie locating piece 5 is not less than 6mm. According to the height of the building and The thickness of the outer concrete protective layer 4, the tie anchors 5 extending into the inner concrete stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com