Basement sealing door

A technology for sealing doors and basements, which is applied in windows/doors, door/window applications, building components, etc., and can solve problems such as unreasonable use of materials and waste of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

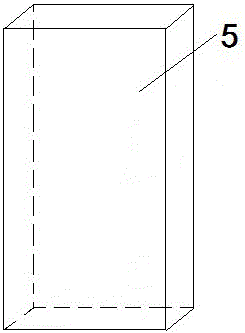

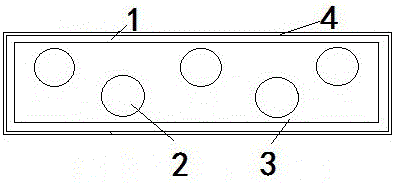

[0043] A basement airtight door, the airtight door includes a concrete airtight door blank and a titanium alloy plate wrapped outside the concrete airtight door blank, the concrete door blank includes a circular steel pipe and concrete wrapped around the circular steel pipe, the outer surface of the titanium alloy plate is coated Corrosion-resistant coating,

[0044] The element composition of titanium alloy plate is: Ni5%, Si2%, V0.6%, Co0.1%, Cr0.08%, Nb0.06%, Mn0.04%, Ce0.02%, the balance is titanium and unavoidable The non-metallic inclusions are smelted according to the composition of the above elements, poured into slabs, and hot-rolled on the slabs. The hot-rolling temperature is 900°C, the deformation of each pass is 15%, and the total deformation is 60%. After hot-rolling, it is air-cooled to room temperature. , remove the oxide film on the surface of the plate, then cold-roll the plate to reduce the thickness of the plate by 6%, then carry out stress relief annealing...

Embodiment 2

[0056] A basement airtight door, the airtight door includes a concrete airtight door blank and a titanium alloy plate wrapped outside the concrete airtight door blank, the concrete door blank includes a circular steel pipe and concrete wrapped around the circular steel pipe, the outer surface of the titanium alloy plate is coated Corrosion-resistant coating,

[0057]The element composition of titanium alloy plate is: Ni6%, Si3%, V0.7%, Co0.2%, Cr0.09%, Nb0.07%, Mn0.05%, Ce0.03%, the balance is titanium and unavoidable The non-metallic inclusions are smelted according to the composition of the above elements, poured into slabs, and hot-rolled on the slabs. The hot-rolling temperature is 900°C, the deformation of each pass is 15%, and the total deformation is 60%. After hot-rolling, it is air-cooled to room temperature. , remove the oxide film on the surface of the plate, then cold-roll the plate to reduce the thickness of the plate by 6%, then carry out stress relief annealing ...

Embodiment 3

[0069] A basement airtight door, the airtight door includes a concrete airtight door blank and a titanium alloy plate wrapped outside the concrete airtight door blank, the concrete door blank includes a circular steel pipe and concrete wrapped around the circular steel pipe, the outer surface of the titanium alloy plate is coated Corrosion-resistant coating,

[0070] The element composition of the titanium alloy plate is: Ni5.5%, Si2.5%, V0.65%, Co0.15%, Cr0.085%, Nb0.065%, Mn0.045%, Ce0.025%, and the balance is Titanium and unavoidable non-metallic inclusions are smelted according to the composition of the above elements, poured into slabs, and the slabs are hot-rolled. The hot-rolling temperature is 900°C, the deformation of each pass is 15%, and the total deformation is 60%. Hot-rolled After air cooling to room temperature, the oxide film on the surface of the plate is removed, and then the plate is cold rolled to reduce the thickness of the plate by 6%, and then the plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com