A grid lining structure for tunnels and its installation method

A network frame and tunnel technology, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems that the steel arch is not easy to be locally strengthened, the lateral stiffness of the steel arch is low, and the plane of the weak axis is twisted and unstable, so as to prevent The effect of destabilizing the pressure bar, improving the stability of the rock mass, and saving support costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

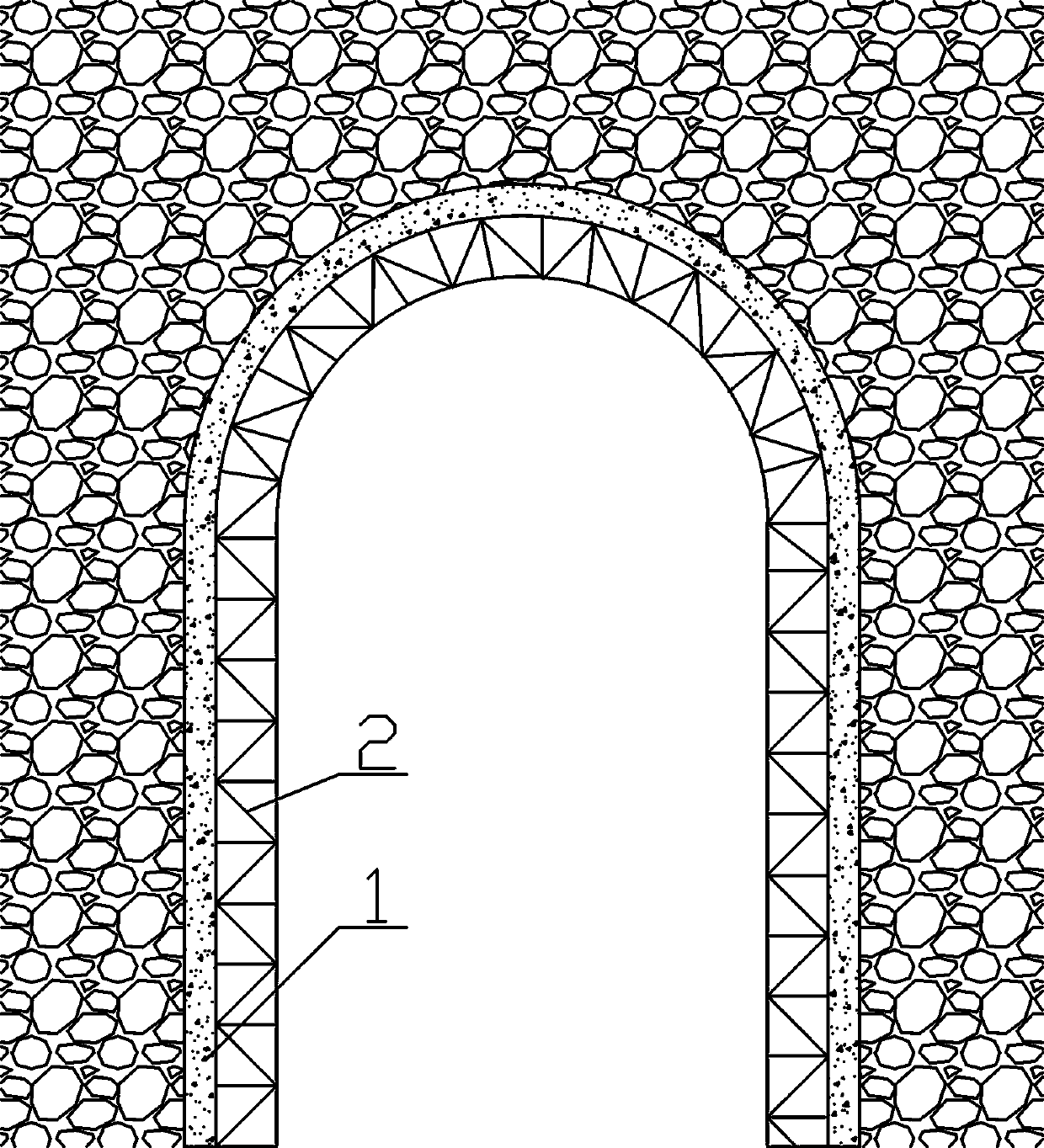

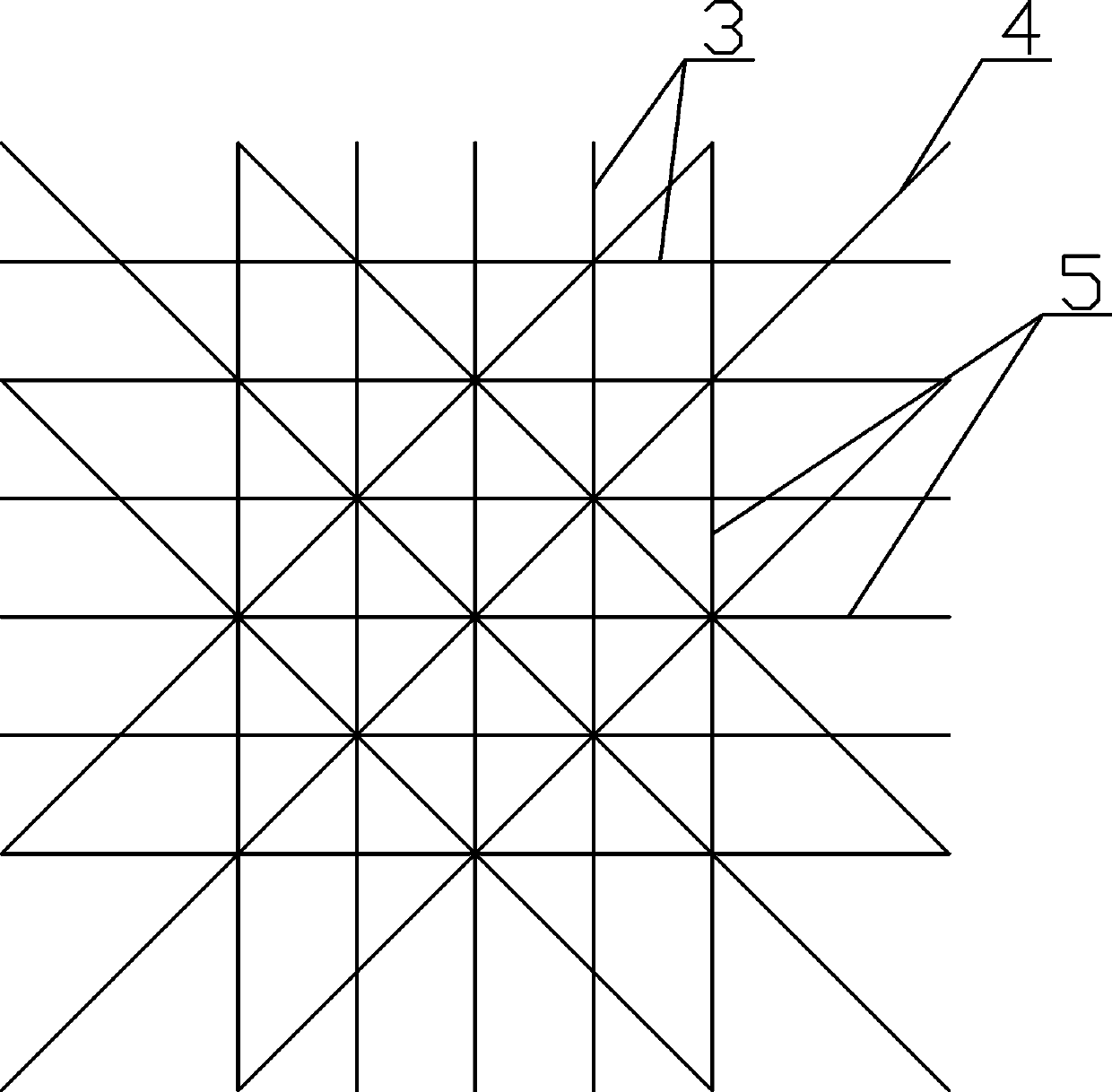

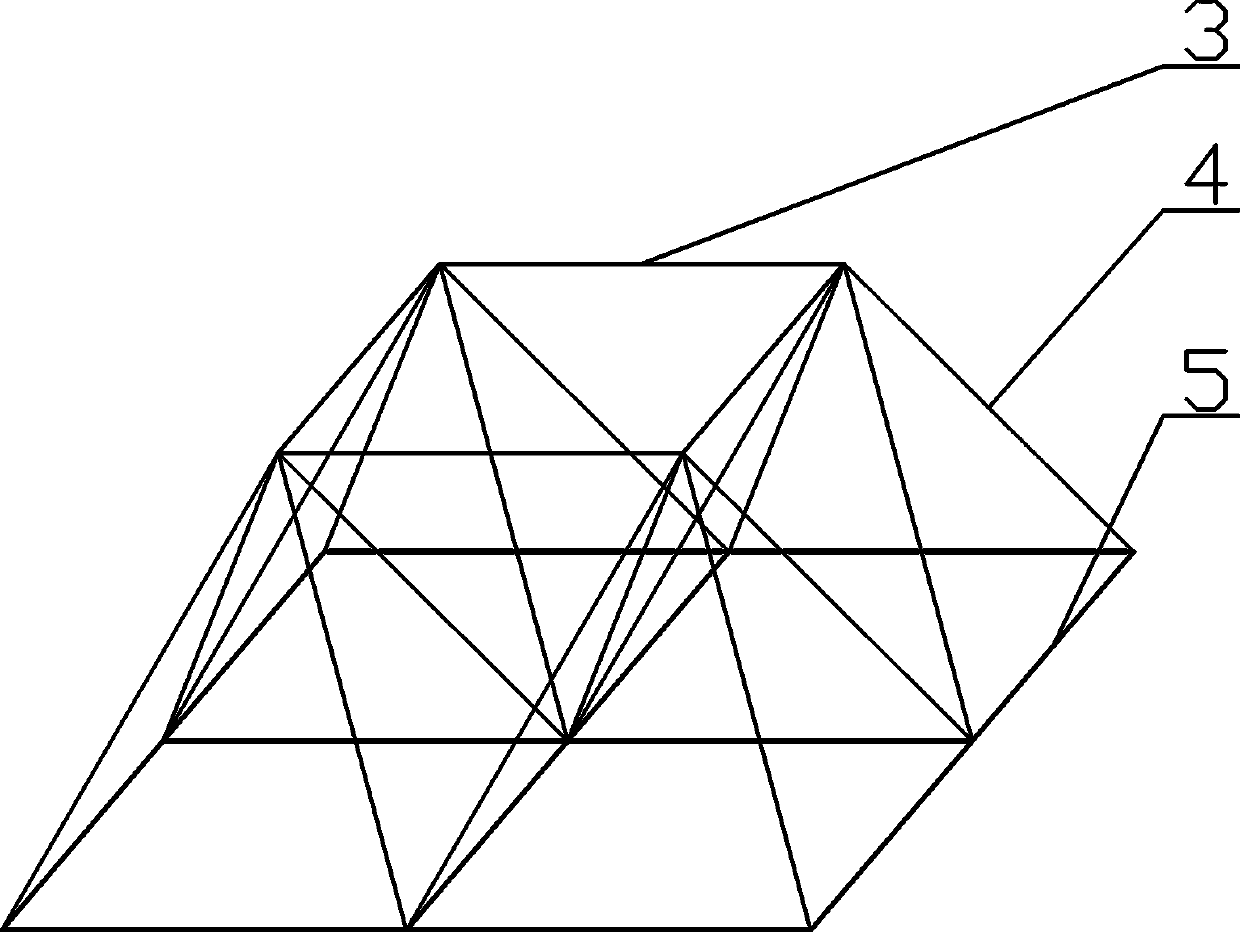

[0027] As shown in the figure, a grid lining structure for a tunnel includes a grid 2, the grid 2 is composed of an inner chord 4, an outer chord 5 and a web 3, and the outer chord 5 and the inner chord 4 form two two mesh surfaces, connected by web bars 3 between the two mesh surfaces;

[0028] The grid frame 2 is arched, and the outer chord 5 is in contact with the surrounding rock.

[0029] In a preferred solution, the network frame 2 is composed of a plurality of quadrangular pyramid units, the bottom surface of the quadrangular pyramid is the outer chord 5 , the four edges are the webs 3 , and the vertices of the quadrangular pyramid are connected by the inner chord 4 .

[0030] In a preferred solution, pressure bars 7 are also provided on both sides of the grid frame 2 .

[0031] In a preferred solution, the pressure rod 7 is a hollow steel pipe, and the pressure rod 7 is filled with expansive concrete 6 .

[0032] In a preferred solution, the 2 legs of the grid frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com