An intake supercharging heating system for a micro internal combustion engine

A technology of air intake pressurization and heating system, applied in the direction of fuel heat treatment device, charging system, combustion engine, etc. Air heating problems, avoiding insufficient air intake, and improving overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

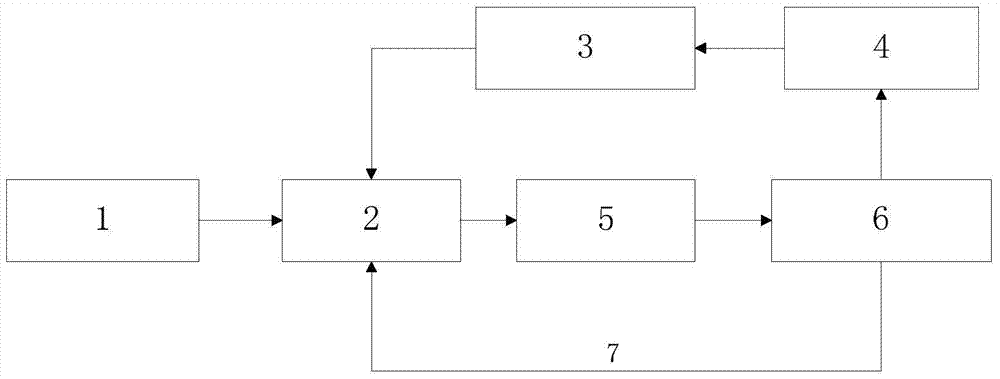

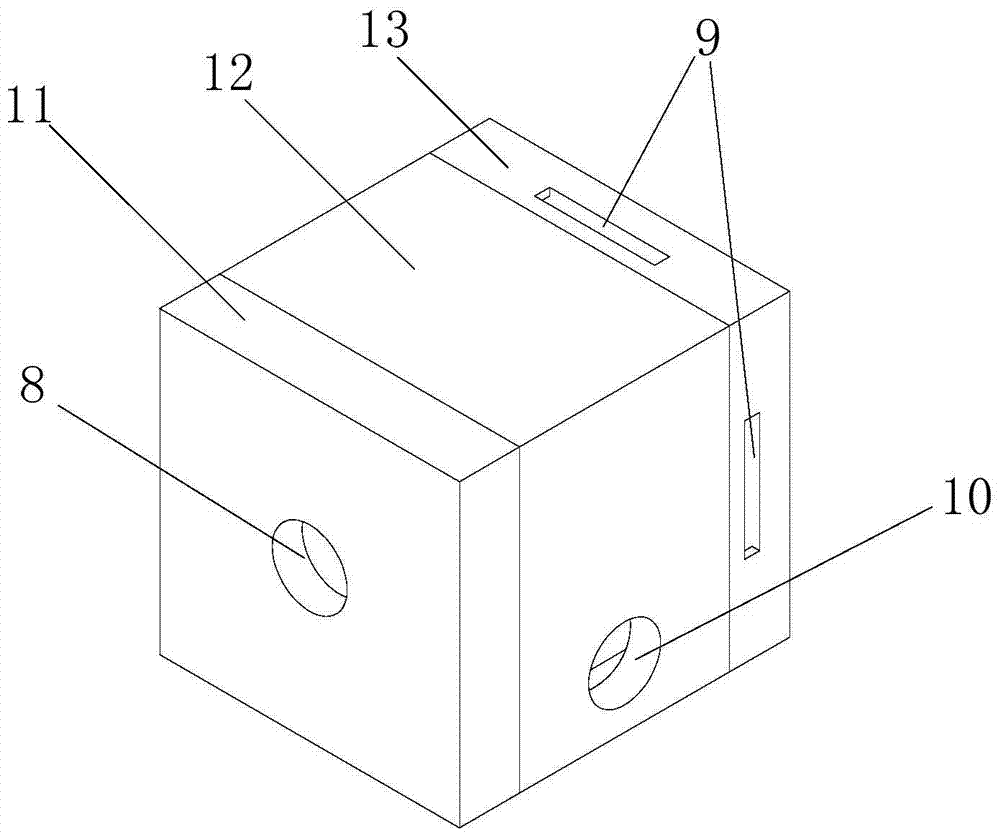

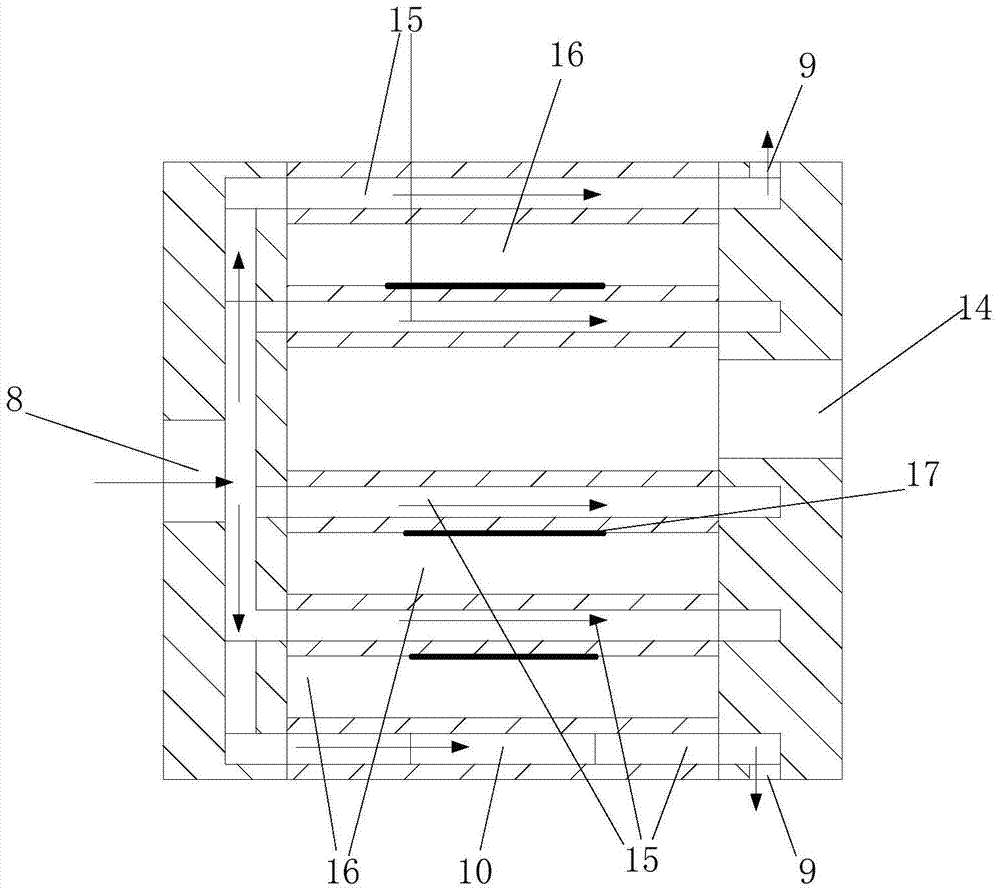

[0036] An intake charge heating system for micro internal combustion engines, such as figure 1 As shown, it includes a booster device 1 , a heating device 2 , an electric heating controller 3 , a thermocouple temperature sensor 4 and an exhaust gas conduit 7 . The outlet of the supercharging device 1 is connected with the supercharged air inlet 10 of the heating device 2 , and the supercharged air exhaust port 14 of the heating device is connected with the carburetor of the miniature internal combustion engine 6 . The thermocouple temperature sensor 4 is arranged at the exhaust port of the micro internal combustion engine 6 , and the exhaust port of the micro internal combustion engine 6 is connected to the high temperature exhaust gas inlet 8 of the heating device 2 through the exhaust gas conduit 7 . The electric heating controller 3 is electrically connected with the thermocouple temperature sensor 4 to receive the temperature signal monitored and transmitted by the thermoc...

Embodiment 2

[0043] An intake air supercharging heating system for a micro internal combustion engine, comprising a supercharging device 1, a heating device 2, an electric heating controller 3, a thermocouple temperature sensor 4, a micro internal combustion engine 6 and an exhaust gas conduit 7;

[0044]The supercharging device 1, the heating device 2 are connected with the miniature internal combustion engine 6 in sequence; the thermocouple temperature sensor 4 collects the exhaust temperature of the miniature internal combustion engine 6, and then transmits it to the electric heating controller 3; the electric heating controller 3 controls the electric heating wire in the heating device 2 Whether 17 is working; the waste gas discharged by the miniature internal combustion engine 6 is discharged into the heating device 2 through the waste gas conduit 7;

[0045] The air intake supercharging heating system also includes a pressure stabilizing valve 5, which is installed between the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com